System and method for side by side virtual-real image inspection of a device

A virtual image and image technology, applied in the direction of using optical devices, details related to 3D image data, image enhancement, etc., can solve problems such as difficult inspection and processing, difficult positioning, and complex shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

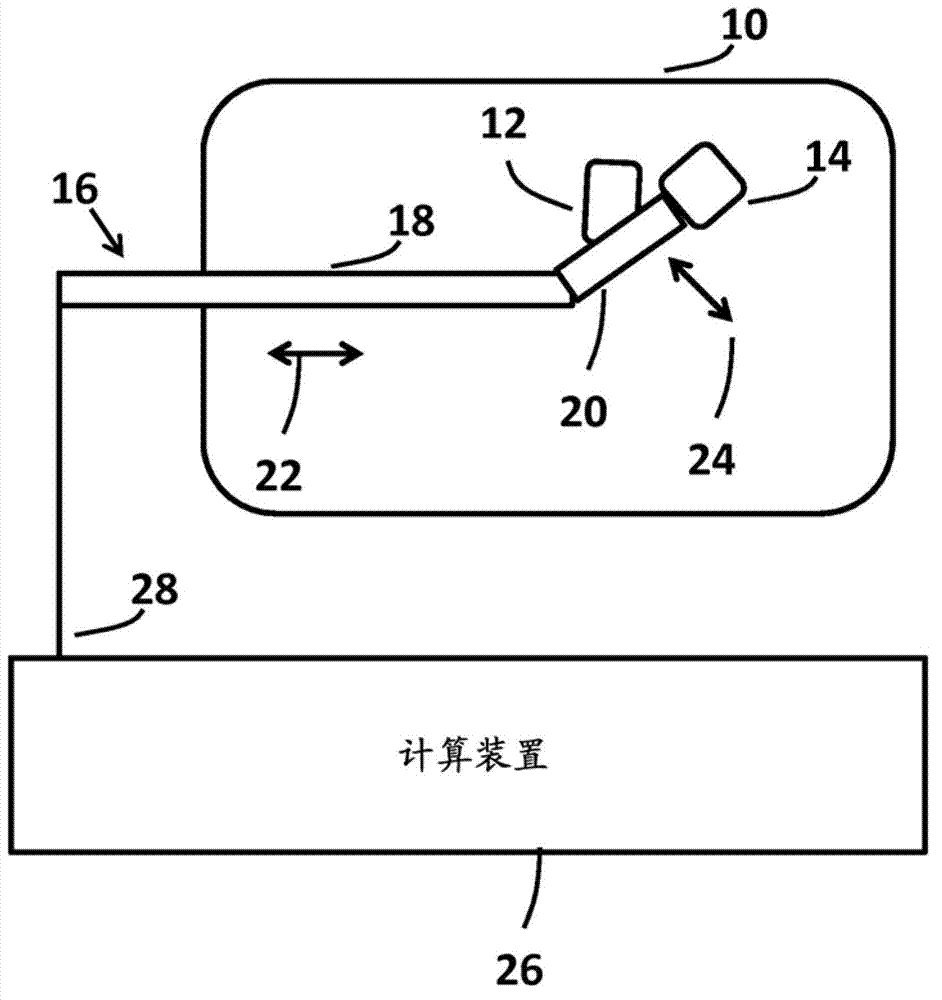

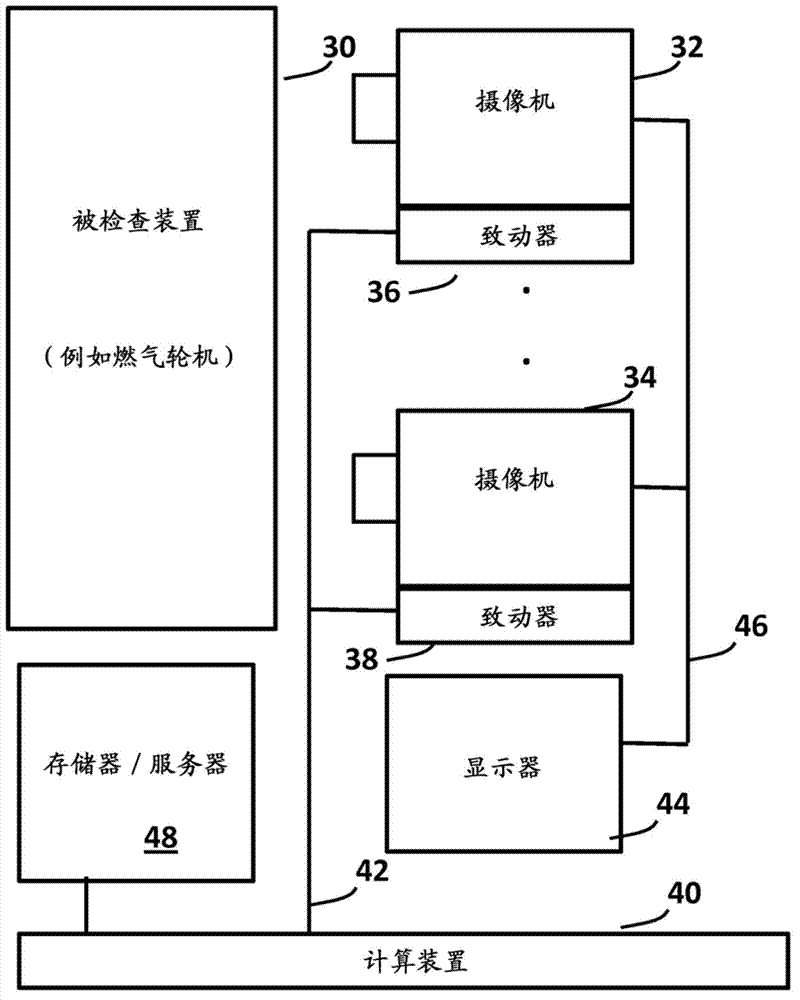

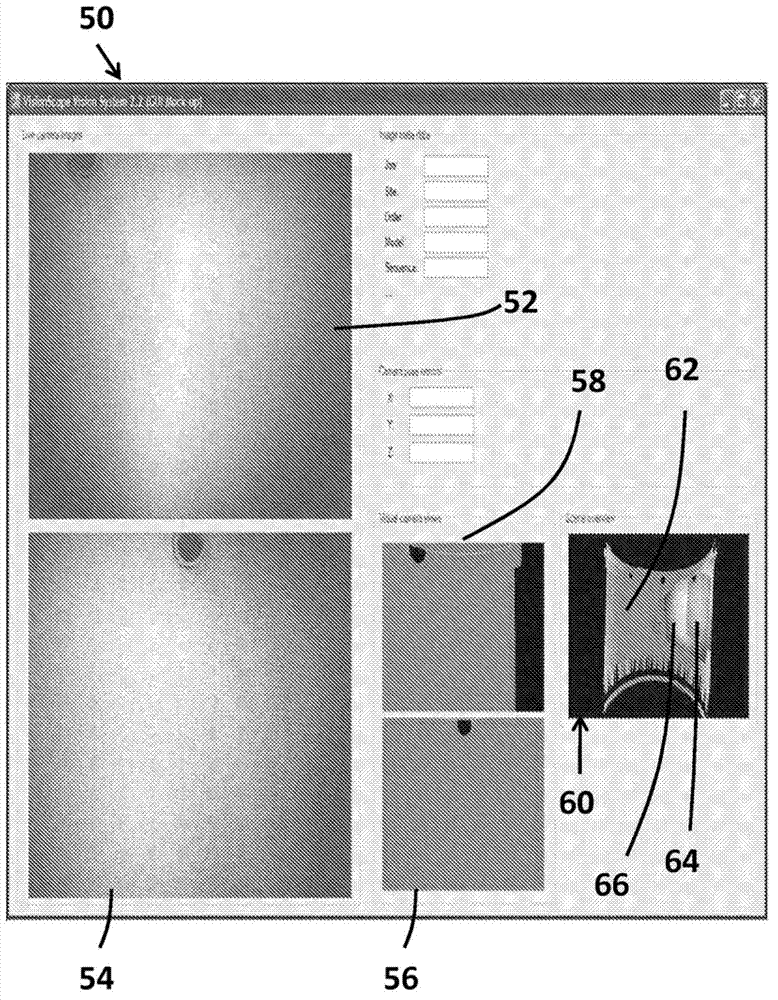

[0027] figure 1 A device under inspection and an inspection system according to an aspect of the present invention are illustrated. The device 10 is shown being inspected. Plant 10 may be any of a number of plants, including turbines, gas turbines, and the like. The inspected device can be quite complex in size as well as in shape. When using a video camera for inspection, it is fairly easy to lose track of where the defect is located. These defects may include damage, cracks, stains, and other defects.

[0028] A plurality of cameras 12, 14 are moved within the inspected device 10 for inspection. The cameras 12 , 14 are mounted on movable, controllable actuators 16 . According to one aspect of the invention, the actuator 16 includes a first arm 18 and a second arm 20 .

[0029] Although two cameras 12, 14 are shown, a single camera could also be used. Alternatively, more than two cameras can also be used.

[0030] The first arm 18 is controllable to move in the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com