Catalyst for arene shape selective reaction and preparation method thereof

A catalyst and reaction technology, used in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalyst strength, low catalyst shape selectivity, etc., and achieve simple preparation methods, low porosity, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

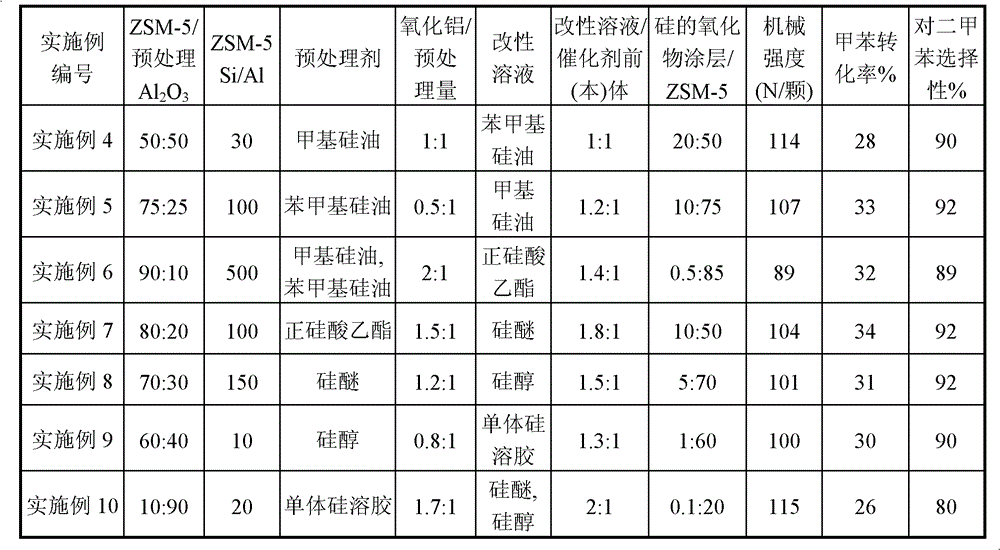

Examples

Embodiment 1

[0014] Mix 10g of alumina with 5g of methicone, grind for 20 minutes, and let stand for 2 hours. Then it is mixed evenly with 90 g of hydrogen-type ZSM-5 zeolite with a silicon-aluminum ratio of 60, shaped, dried, and calcined at 500° C. for 4 hours to obtain a catalyst precursor.

[0015] Put the catalyst precursor into 120g of methyl silicone oil solution, carry out the chemical liquid phase deposition reaction at 25°C for 3 hours, filter and dry it, and bake it in an air atmosphere at 500°C for 4 hours to obtain a catalyst body.

[0016] Then, the above-mentioned steps of the modified catalytic body were continued to be modified by chemical liquid phase deposition for 3 times. The mechanical strength of the obtained catalyst was 110N / particle. The catalyst was evaluated at 435°C and a pressure of 2.0mpa, using pure toluene as a raw material, and taking samples for analysis after 2 hours of reaction. It is calculated that the conversion rate of toluene in the toluene shape...

Embodiment 2

[0018] 20 g of alumina was mixed with 15 g of tetraethyl orthosilicate, milled for 60 minutes, and allowed to stand for 4 hours. Then it is mixed evenly with 80 g of hydrogen-type ZSM-5 zeolite with a silicon-aluminum ratio of 80, shaped, dried, and calcined at 450° C. for 3 hours to obtain a catalyst precursor.

[0019] Put the catalyst precursor into 140g of phenylmethyl silicone oil solution, carry out the chemical liquid phase deposition reaction at 25°C for 3 hours, filter and dry it, and roast it under the air atmosphere of 450°C for 3 hours to obtain the primary modified catalyst .

[0020] Then the catalyst body was modified by chemical liquid phase deposition for 2 times according to the above steps. The mechanical strength of the obtained catalyst was 105 N / particle. The catalyst was evaluated at 400°C and a pressure of 2.0mpa. Pure toluene and methanol were used as raw materials, and the molar ratio of toluene to methanol was 2:1. After 2 hours of reaction, sample...

Embodiment 3

[0022] Mix 30g of alumina with 30g of tetraethyl orthosilicate, grind for 45 minutes, and let stand for 4 hours. Then it is mixed evenly with 70 g of hydrogen-type ZSM-5 zeolite with a silicon-to-aluminum ratio of 75, shaped, dried, and calcined at 450° C. for 3 hours to obtain a catalyst precursor.

[0023] Put the catalyst precursor into 135g tetraethyl orthosilicate solution, carry out the chemical liquid phase deposition reaction at 25°C for 3 hours, filter, dry, and roast at 550°C for 3 hours in an air atmosphere to obtain the catalyst body.

[0024] Then the catalyst body was modified by chemical liquid phase deposition for one time according to the above steps. The mechanical strength of the obtained catalyst was 118N / particle. The catalyst was evaluated at 450°C and a pressure of 2.0mpa, using pure ethylbenzene as a raw material, and taking samples for analysis after 2 hours of reaction. It is calculated that the ethylbenzene conversion rate in the ethylbenzene selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com