Double-ejection device for improved-type injection mold

An injection mold and secondary ejection technology, applied in the field of plastic molds, can solve the problems of abnormal production, high repair rate, high labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

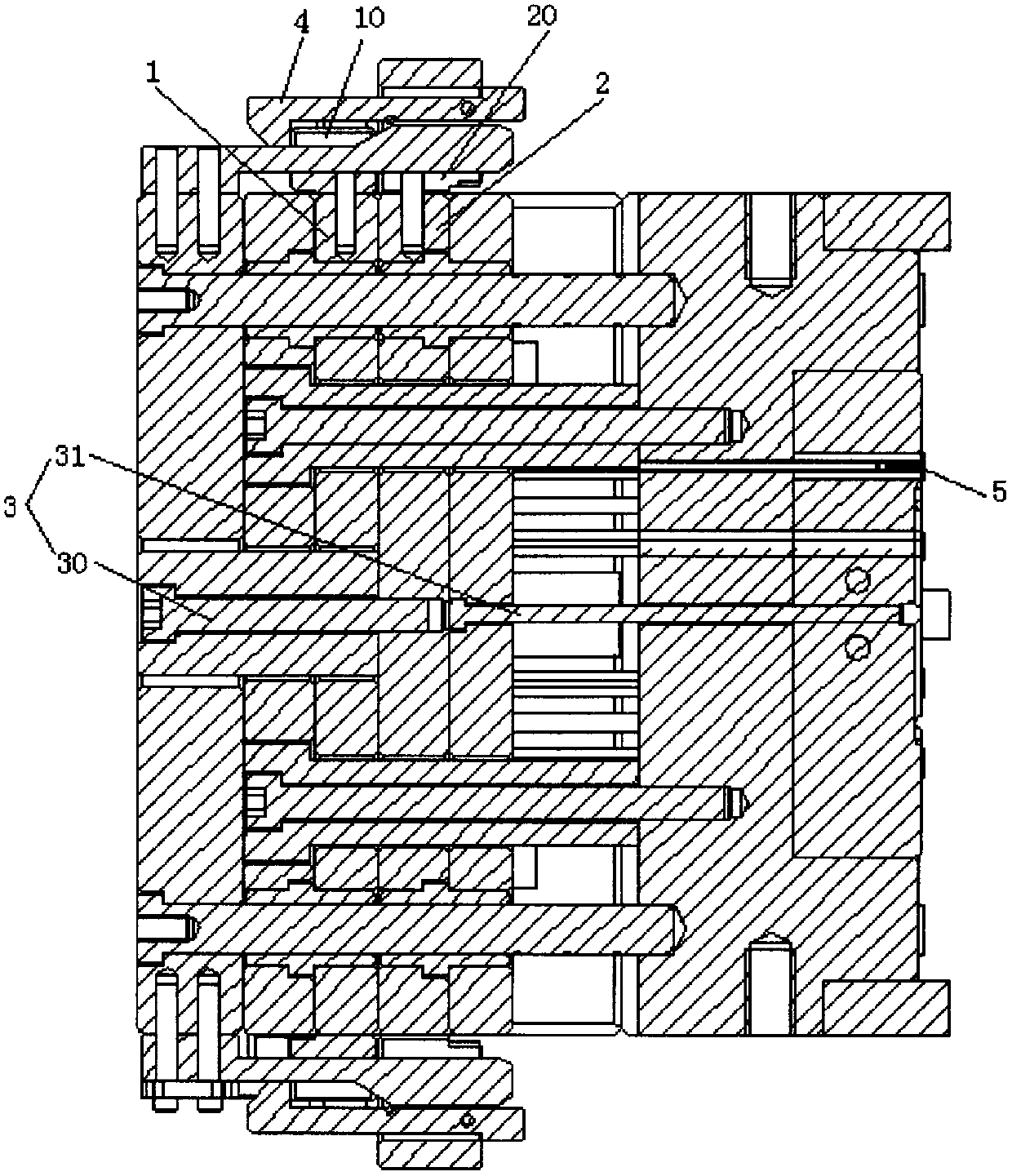

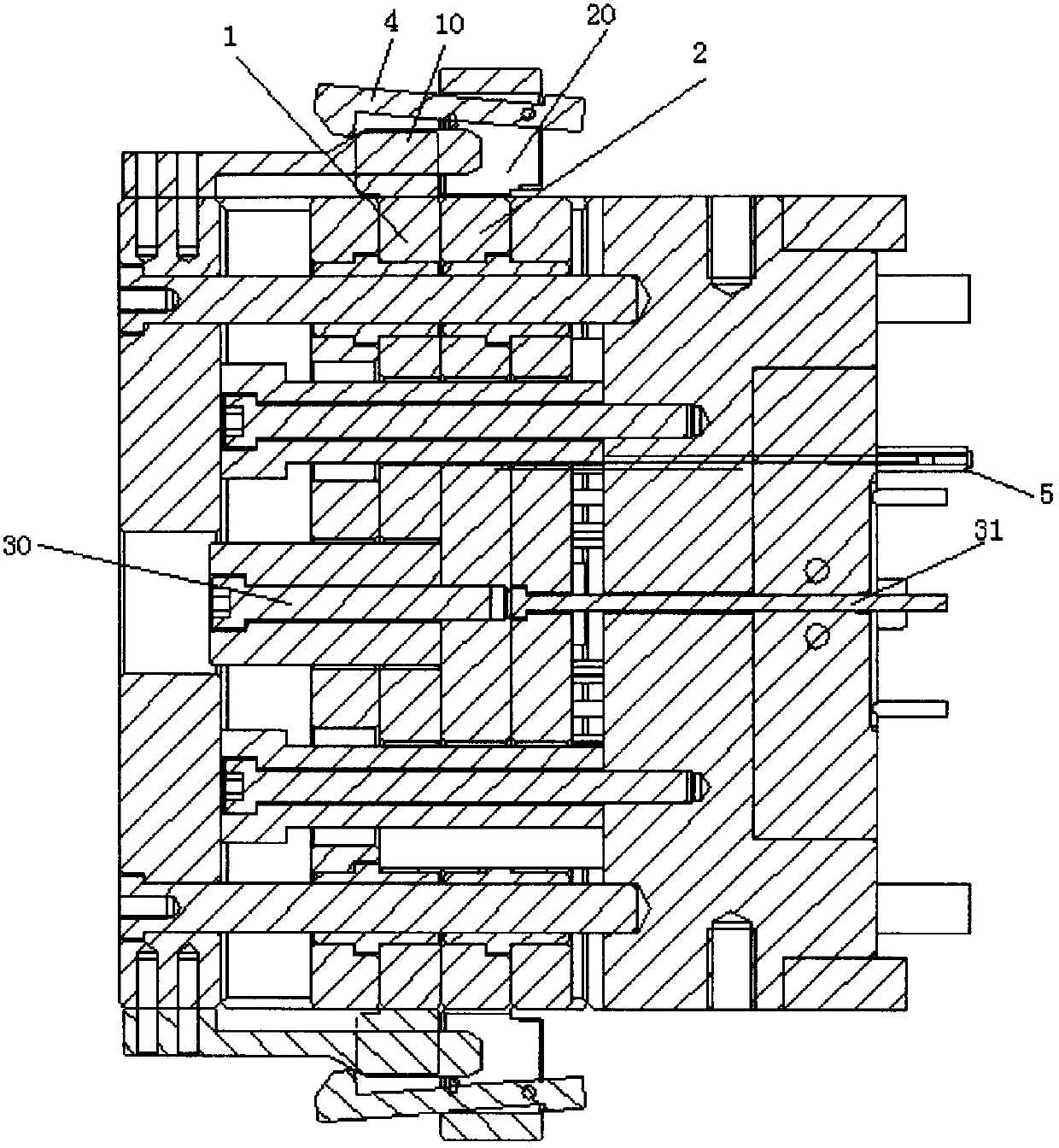

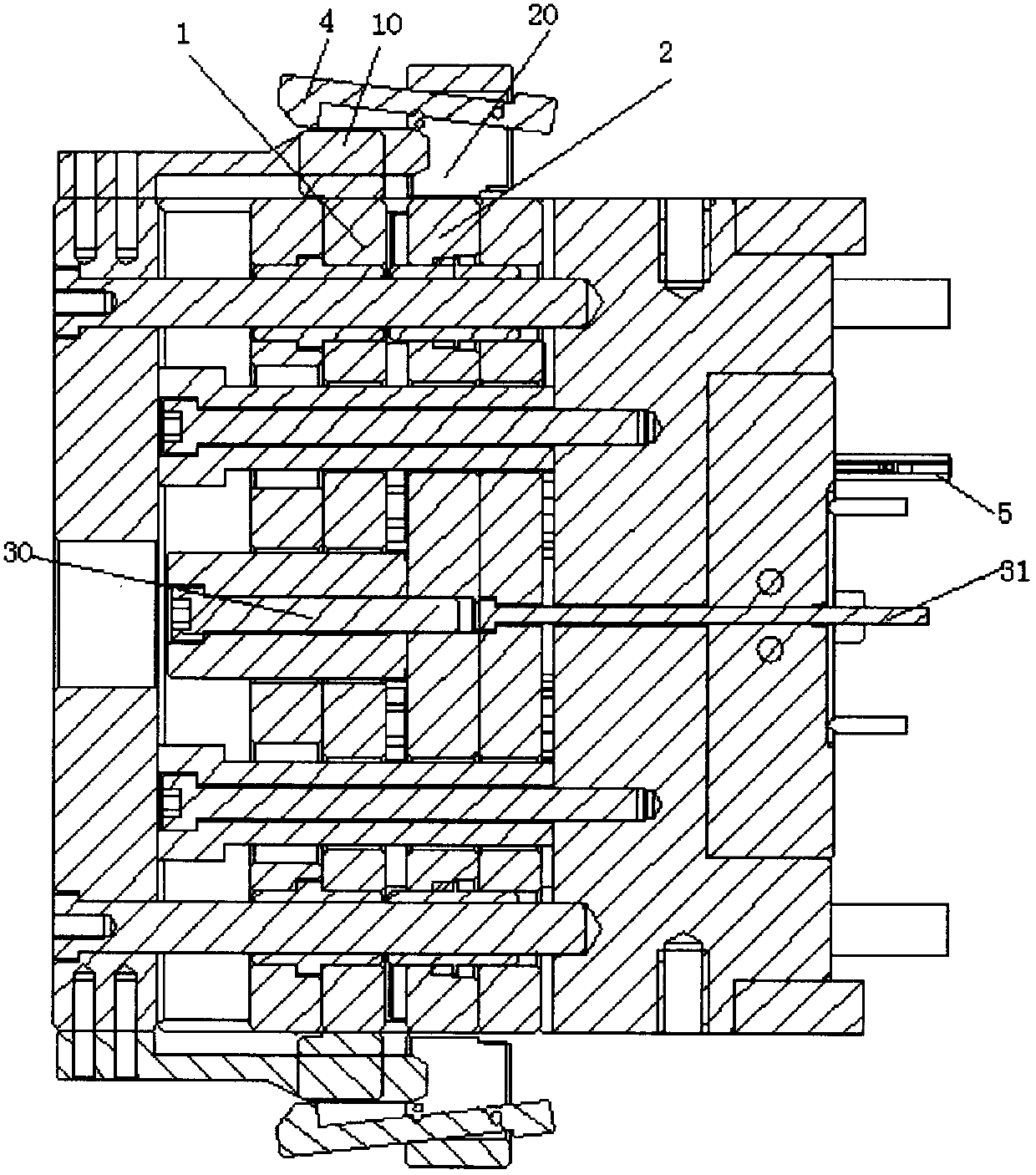

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0013] see figure 1 , figure 2 with image 3 , the embodiment of the present invention includes: a secondary ejection device for an improved injection mold, including: a first splint 1, a second splint 2, an ejector rod 3 and a hook 4, and first stops are respectively arranged on both sides of the first splint 1 Block 10, the two sides of the second splint 2 are respectively provided with second stoppers 20, the hook 4 is hooked on the first stopper 10 through the sliding support plate 5, and the push rod 3 is connected in series on the first splint 1 and the second splint at the same time. Middle of splint 2.

[0014] Further, the ejector ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com