Knitted fabric and application thereof

A technology of knitted fabric and section, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of low dyeing fastness, low dyeing fastness, mildew and deterioration of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

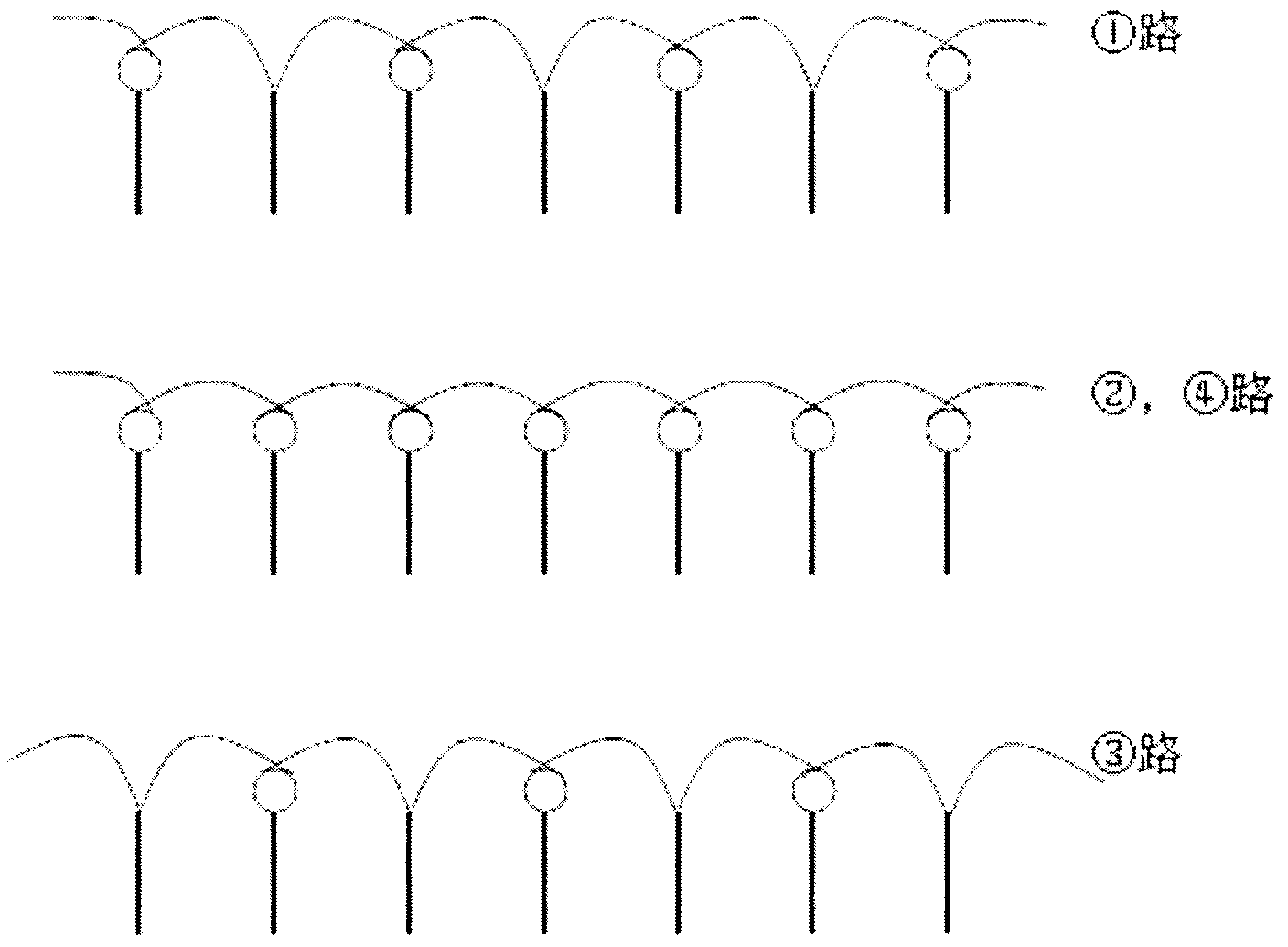

[0038] Using 40S PET MVS yarn and 75D-24f-high-shrinkage PET yarn for cross-knitting, the weave is beaded weave, knitting on a 32G single-jersey machine to form a knitted gray fabric, and the obtained knitted gray fabric contains 75D-24f-high-shrinkage PET yarn The blending rate of the high-shrinkage yarn is 32%, and the boiling water shrinkage rate of its high-shrinkage yarn is 38%. After scouring and desizing in the cylinder (scouring agent 0.5g / l), dyeing with disperse dyes at 130 degrees, resin finishing (hydrophilic agent 10g / l, pH regulator 1g / l), finishing and shaping at 160 degrees, the gram weight is about 200g / m 2 of knitted fabrics. The underfill coefficient of the knitted fabric is 12, and the loop shrinkage rate of the knitted fabric is 14% compared with that before dyeing.

[0039] The knitted fabric has a pilling resistance of grade 4, and the change rate of the washing inch method is -0.7% in the warp direction and -0.2% in the weft direction. The stiffness ...

Embodiment 2

[0041] Using 60S PET MVS yarn and 50D-24f-high-shrinkage PET yarn for cross-knitting, the weave is beaded weave, knitting on a 36G single-jersey machine to form a knitted gray fabric, and the obtained knitted gray fabric contains 50D-24f-high-shrinkage PET yarn The blending rate of the high-shrinkage yarn is 54%, and the boiling water shrinkage rate of its high-shrinkage yarn is 33%. After scouring and desizing in the tank (scouring agent 0.5g / l), dyeing with disperse dyes at 130 degrees, resin finishing (hydrophilic agent 10g / l, PH value regulator 1g / l), finishing and shaping at 160 degrees, the gram weight is about 180g / m 2 of knitted fabrics. The underfill coefficient of the knitted fabric is 15, and the loop shrinkage rate of the knitted fabric is 12% compared with that before dyeing.

[0042] The knitted fabric has a pilling resistance of 4 grades, and the change rate of the washing inch method is -2.0% in the warp direction and -0.3% in the weft direction. The stiffne...

Embodiment 3

[0044] Using 75D-96f-special-shaped section PET DTY yarn and 75D-24f-high-shrinkage PET yarn for interknitting, the weave adopts 1:1 plain jersey weave, and knits it on a 36G single-jersey machine to form a knitted gray fabric. The mixing rate of 75D-24f-high shrinkage PET yarn is 50%, and the boiling water shrinkage rate of its high shrinkage yarn is 38%. After scouring and desizing in the tank (scouring agent 0.5g / l), dyeing with disperse dyes at 130 degrees, resin finishing (hydrophilic agent 10g / l, PH value regulator 1g / l), finishing and shaping at 160 degrees, the gram weight is about 180g / m 2 of knitted fabrics. The underfill coefficient of the knitted fabric is 18, and the loop shrinkage rate of the knitted fabric is 10% compared with that before dyeing.

[0045]The pilling resistance of the knitted fabric is grade 4, and the change rate of the washing inch method is -0.2% in the warp direction and -0.6% in the weft direction. The stiffness in the warp direction is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling water shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com