Composite sealing device of Roots blower end cover

A technology of roots blower and sealing device, applied in the sealing device of piston pump, mechanical equipment, machine/engine, etc., can solve the problems of failure of sealing surface, not very good effect, poor effect, etc. Effect

Inactive Publication Date: 2013-05-29

YIXING UNITE MACHINERY

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, when transporting some special gases, mechanical seals are generally used for sealing. At present, mechanical seals are mainly added between the end cover and the bearing to isolate lubricating oil and gas in the market, but the effect is not good, and some gases will directly impact the mechanical seal. Long-term operation will lead to the failure of the sealing surface. Some manufacturers add a labyrinth seal in front of the mechanical seal, but the effect is not very good. The impact of the gas on the mechanical seal cannot be changed, which will eventually lead to the failure of the sealing surface.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

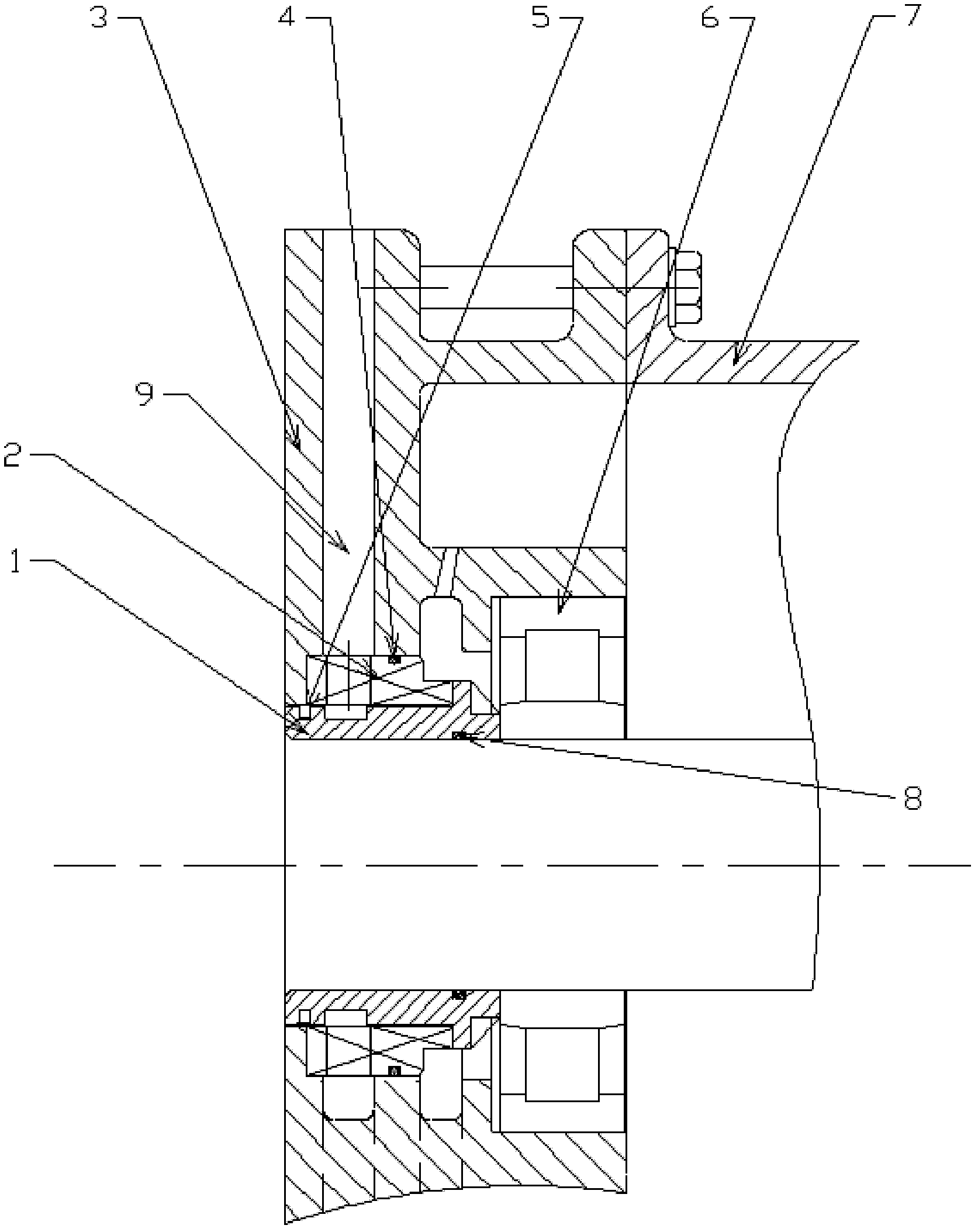

A composite sealing device of a Roots blower end cover is characterized by comprising a composite moving ring (1), a stationary ring (2), a stationary O-shaped ring (4), a moving O-shaped ring (8) and a pressure relief hole (9). The stationary ring (2) is mounted on the Roots blower end cover (3), the pressure relief hole (9) is reserved in the middle of the end cover (3), and the end cover (3) is sealed with the front portion of the stationary ring (2) through the stationary O-shaped ring (4). The composite moving ring (1) is a long sleeve and is connected with a shaft of the Roots blower through the moving O-shaped ring (8). The composite moving ring (1) is provided with a piston ring groove, and a piston ring (5) is mounted in the piston ring groove. By the aid of the composite sealing device of the Roots blower end cover, reliability of mechanical seal is improved, direct impacts to mechanical seal end surface by a small amount of gas leaked through piston ring seal are avoided, and especially when the Roots blower delivers special gas, security and reliability of oil and gas seal of the Roots blower are greatly improved.

Description

technical field [0001] The invention relates to the technical field of Roots blower sealing, in particular to a Roots blower end cover composite type for preventing the leakage risk of these special gases when the Roots blower is transporting special gases (such as methane, water vapor, etc.). Sealing means. Background technique [0002] Generally, Roots blowers are used for air transportation, which has very low requirements for sealing. The gas on the end cover is mainly sealed through the skeleton structure or the labyrinth. Generally, there are holes for the atmosphere on the end cover, allowing Part of the air leaks out from the hole, and an ordinary skeleton oil seal is used on the side close to the bearing to achieve the effect of oil sealing. The skeleton oil seal has high requirements on the size of the installation hole, and the rubber is easy to age when used at high temperature for a long time. The reaction between gas and rubber should also be taken into acco...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04C27/00

Inventor 朱文强毛法良蒋万军

Owner YIXING UNITE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com