Method and apparatus for treating a bed of particulated material

A technology for granular materials and equipment, which is used in the field of processing granular material beds and equipment, and can solve problems such as high pressure loss and excessive fan design size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

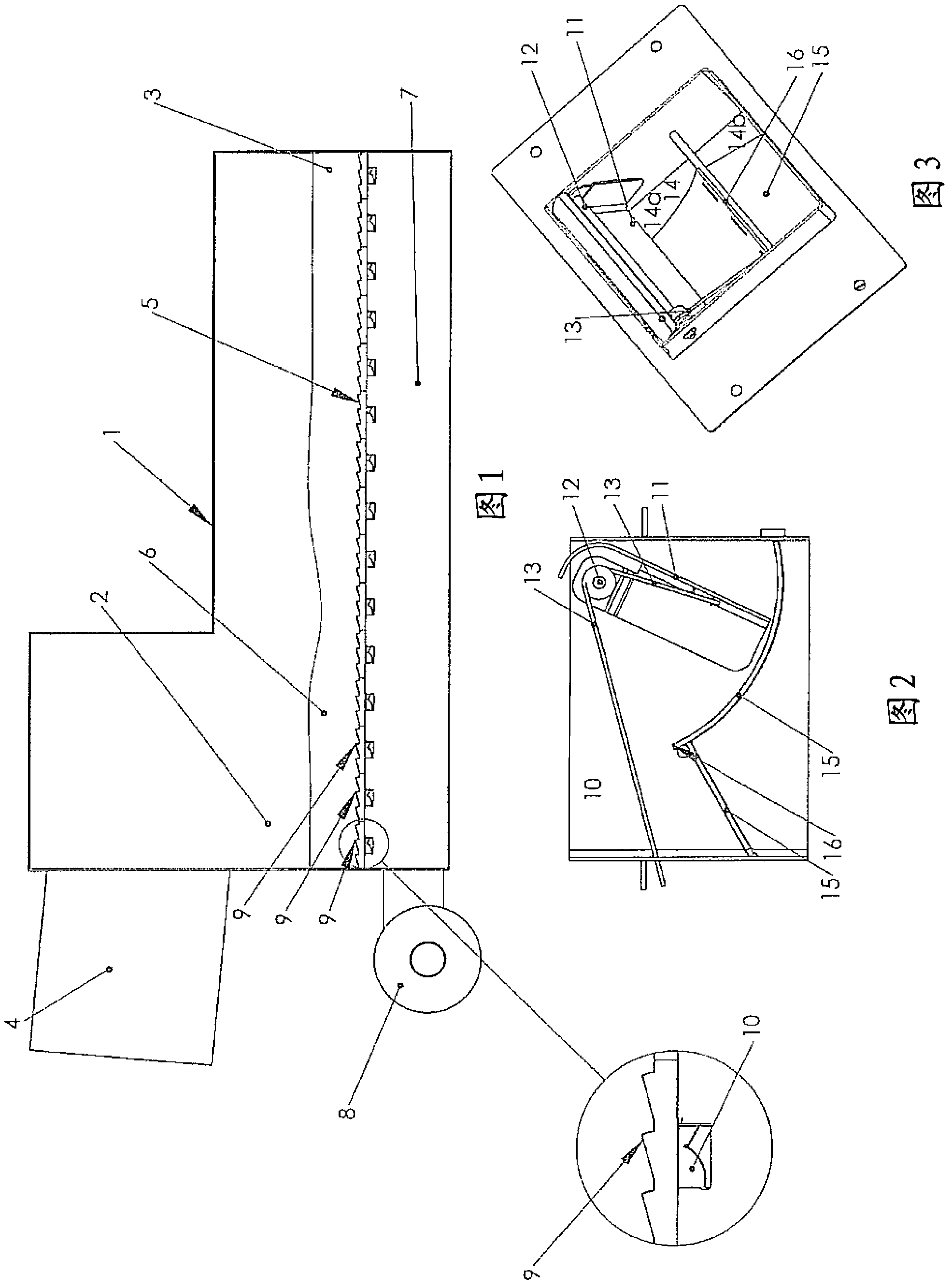

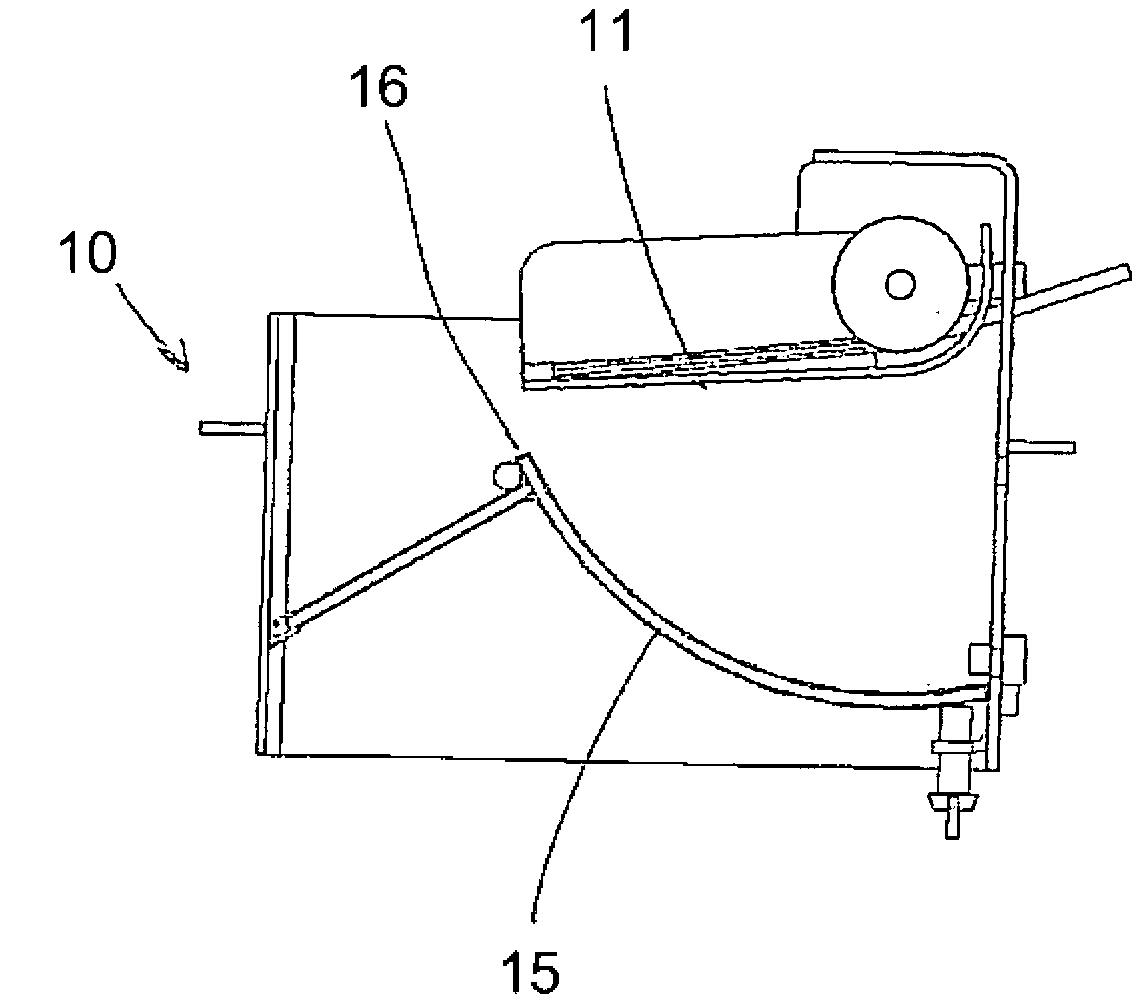

[0032] figure 1A cooler 1 is shown comprising an inlet port 2 and an outlet port 3 . The cooler is connected to the rotary kiln 4 from which the cooler receives the hot material to be cooled. The material coming from the rotary kiln 4 falls on the distribution bottom 5 arranged in the cooler 1 and the material is conveyed as a material layer 6 on the distribution bottom 5 from the inlet port 2 to the outlet by means of transport means (not shown) End 3. The transport device may be, but is not limited to, a reciprocating grate, a reciprocating pole, or a ground running device. The cooler 1 comprises one or more compartments 7 below the distribution bottom 5 , wherein each compartment is supplied with cooling air from a fan arrangement 8 . The compartment 7 may be divided into a plurality of smaller compartments (not shown) longitudinally and transversely of the cooling machine 1, and if so divided, cooling air is supplied to each individual compartment. The distribution bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

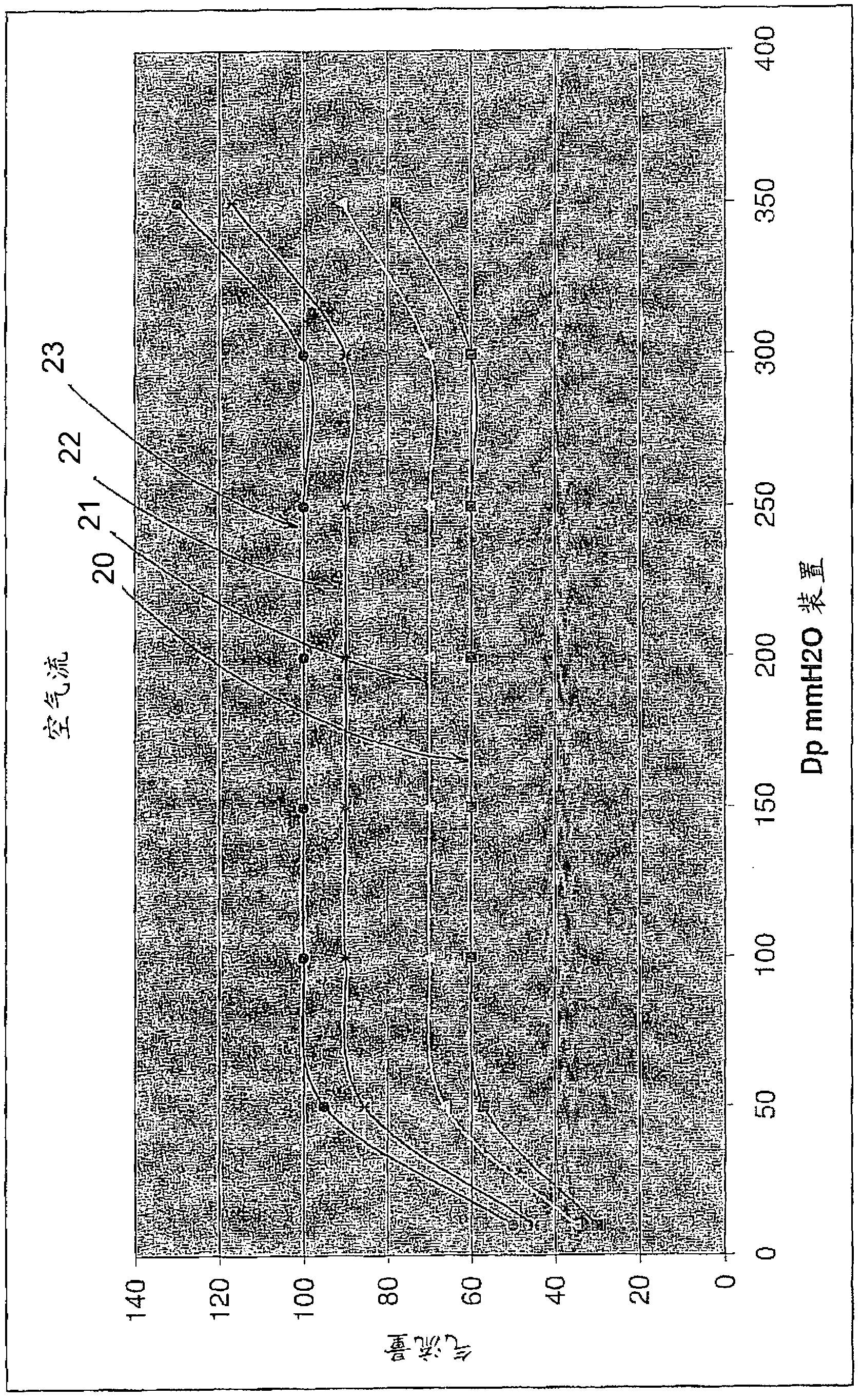

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com