Rod tote box manipulator, circulation box and tote box filling level changing method

A technology for moving boxes and filling, which is applied in food science, applications, tobacco, etc., can solve problems such as downtime and difficult operation processes, and achieve the effects of reducing the number, improving process reliability, and optimizing space location requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

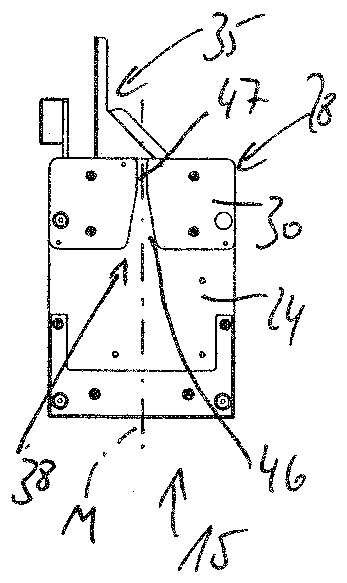

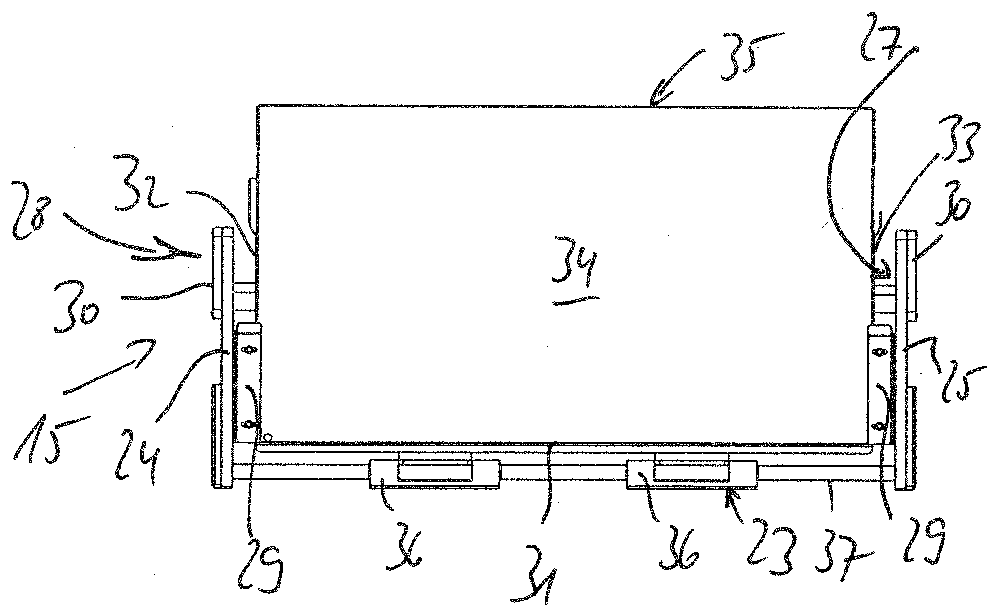

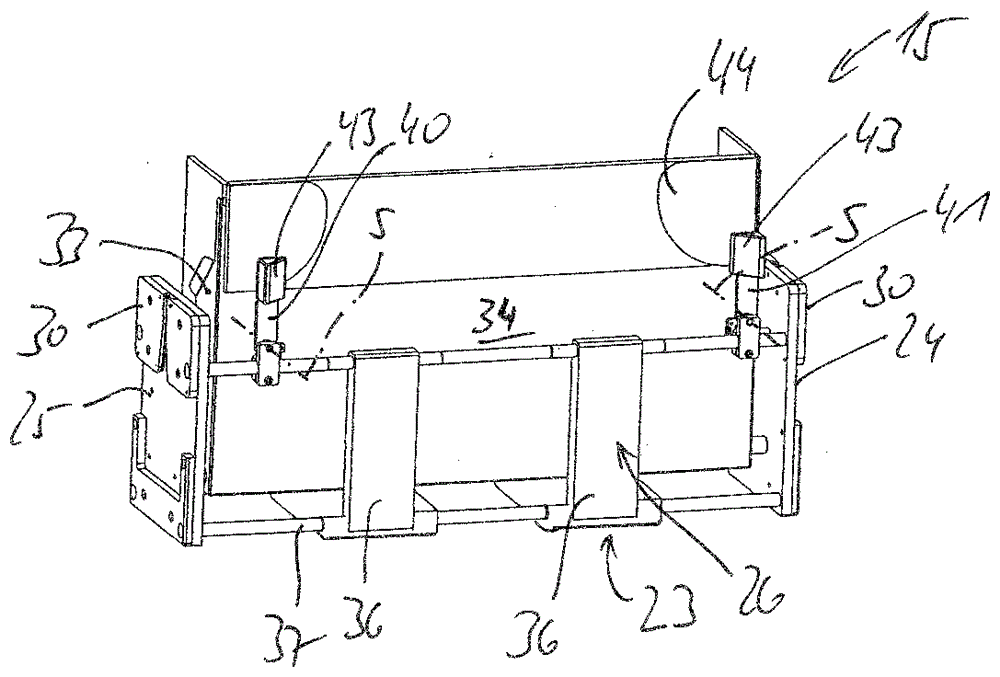

[0043] The device and the recycle box shown in the drawing are used for handling, in particular for emptying and filling shipping boxes made of cardboard, cardboard or the like, so-called cardboard with foldable or reversible lids Trays. Of course, the device and the recycle box are also suitable for handling uncovered tote boxes made of cardboard, cardboard or the like and also for handling conventional trays made of plastic.

[0044] Figures 1 to 5 Accordingly, a device 10 is shown, which is configured and provided for handling a handling case 11 for rod-shaped products for the tobacco processing industry. Said device 10 comprises a device 12 for varying the filling level of totes 11 which are empty or filled with rod-shaped products of the tobacco processing industry. exist figure 1 and 2 In this case, the device 12 is a so-called tray loader. exist Figures 3 to 5 In this case, the device 12 is a so-called pan emptyer. Furthermore, each device 10 comprises a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com