Embedded tensioner

A tensioner and tensioning technology, applied in the direction of wire tensioning appliances, manufacturing tools, etc., can solve the problems of distortion, low bearing capacity, and serious corrosion of the support seat, so as to improve the tensioning strength, improve the bearing strength, The effect of increasing the intensity of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

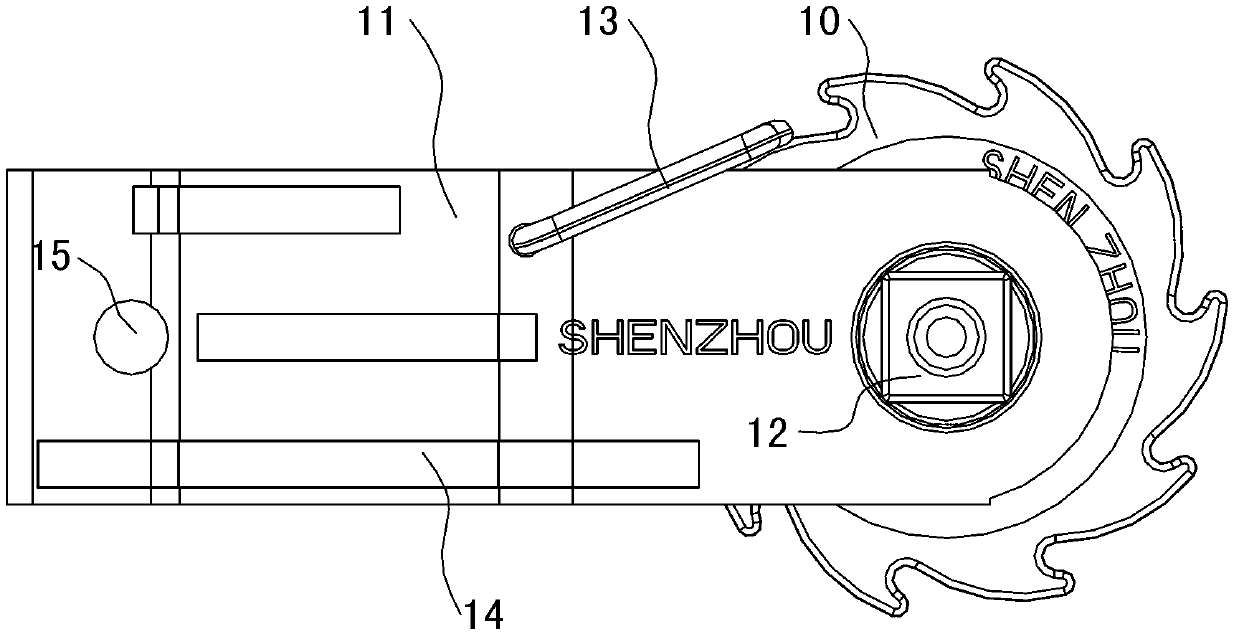

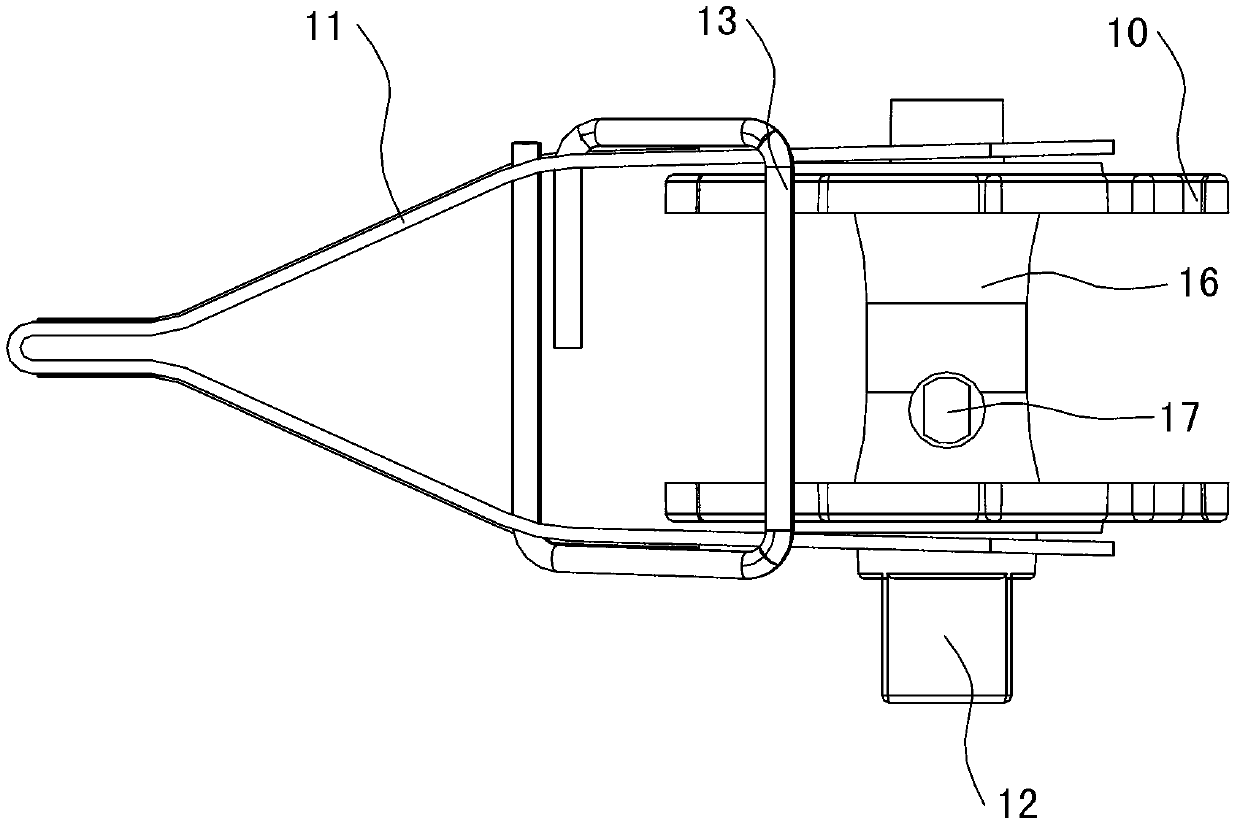

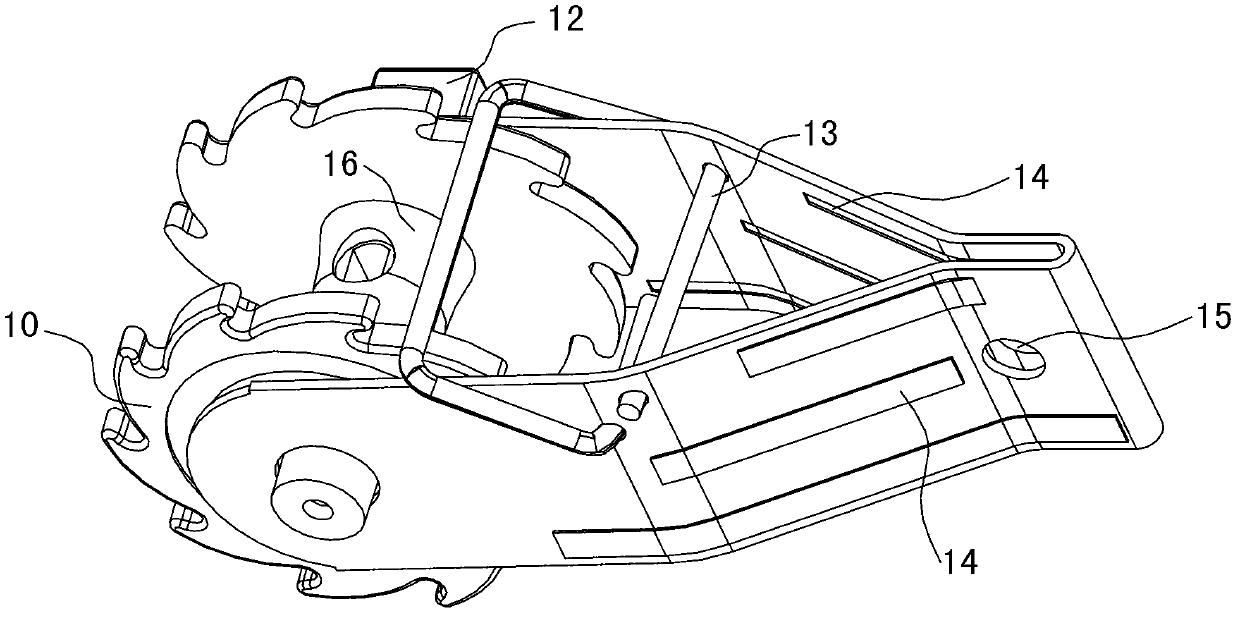

[0028] a kind of like Figure 1-3 , Figure 4-6 The embedded tensioner shown includes a support base 11, on which a ratchet shaft 16 at the movable end of the winding wire is rotated, and a tensioning ratchet 10 is provided at both ends of the ratchet shaft 16, and the support base 11 is provided with The anti-retraction pawl 13 that can cooperate with the tensioning ratchet 10 is provided with a wire fixed end fixing hole 15 and a wire movable end fixing hole 17 on the support base 11 and the ratchet shaft 16 respectively, wherein the wire fixing end fixing hole 15 The tensioning direction of the fixed line is on the vertical line of the ratchet shaft 16 between the tensioning ratchets 10, and the fixed hole 17 at the movable end of the line runs through the ratchet shaft 16 between the tensioning ratchets 10 at both ends , and the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com