Airless tire

A technology of airless tires and outer belts, applied to non-pneumatic tires, tire parts, wheels, etc., can solve the problems of reducing driving performance and achieve the effect of improving uniformity and radial runout performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

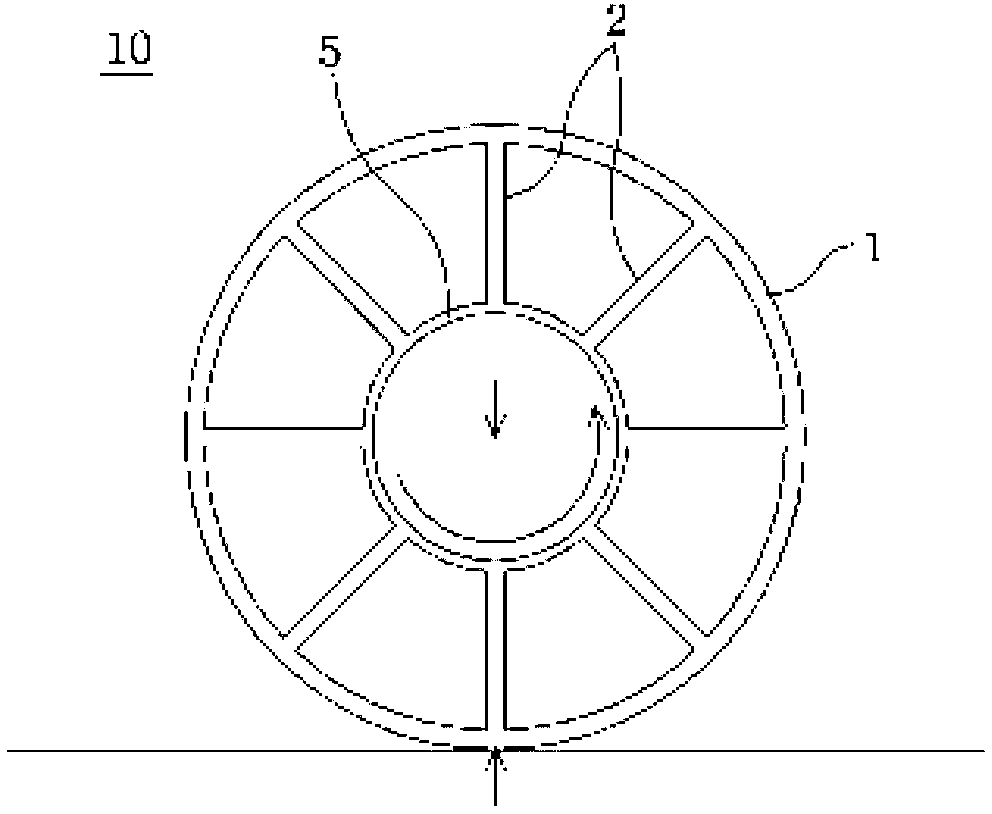

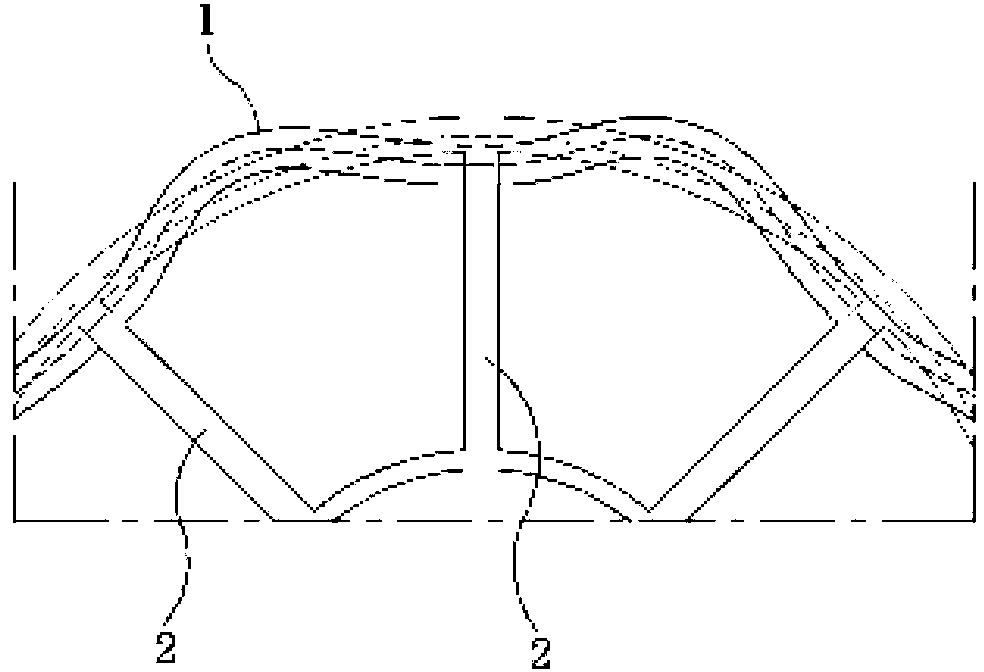

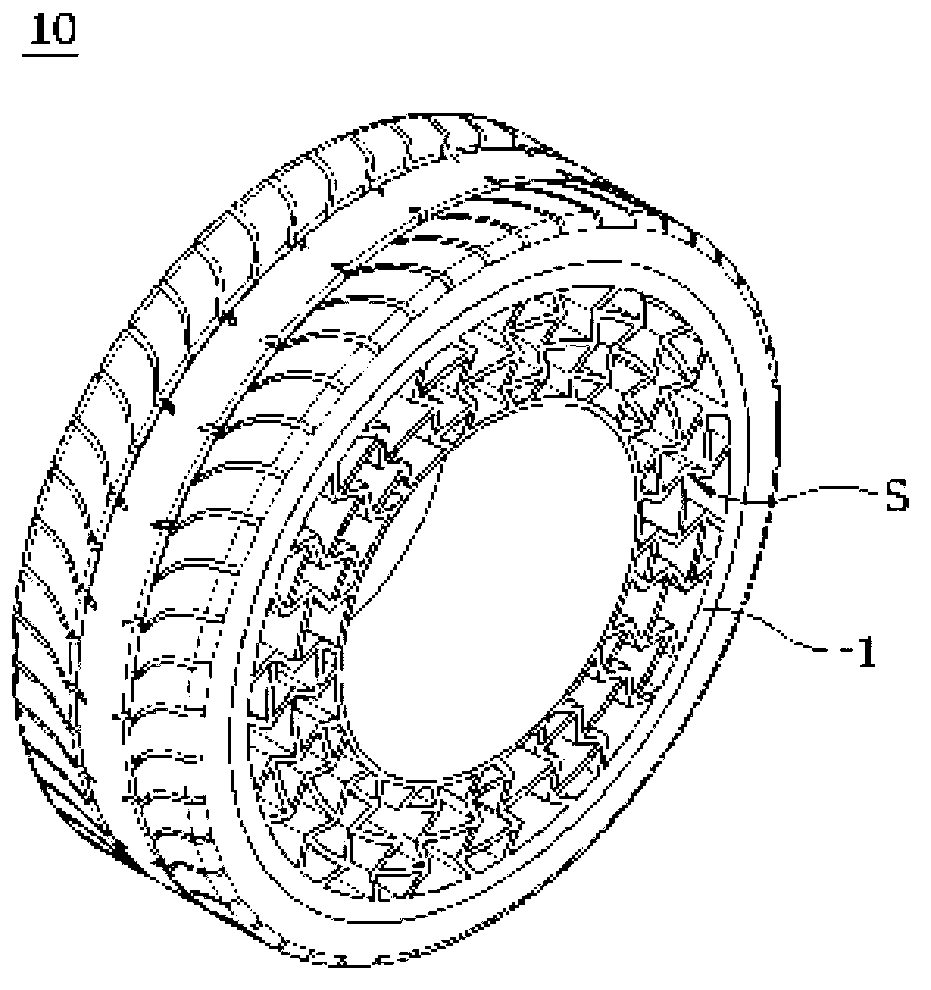

[0034] An airless tire according to the present invention includes an outer belt and a structure provided inside the outer belt. The structure is formed in the radial direction of the tire and includes a plurality of spokes attached to the inner side of the outer belt. Depending on the design of the airless tire, the shape and number of spokes can be changed in various ways.

[0035] The outermost spokes of the structure are connected to the inner side of the outer band. At this time, in order to increase the contact area between the spoke and the outer band, a leg portion is formed at the connection portion between the spoke and the outer band. By further forming the foot portion, the influence of the stress formed on the spoke on the inner surface of the outer band can be reduced. The pedestal portions may be manufactured separately from the spokes and then bonded or welded to the junctions of the spokes and the outer straps. Furthermore, the foot part can be manufactured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com