Permanent-magnet suction lift device utilizing magnetic module

A permanent magnet suction lifter, magnetic technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of reduced suction and lifting capacity, poor suction and lifting capacity of thin plates, large loss of magnetic system suction, etc. Lowering, good suction and lifting capacity, simple and clear control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific implementation examples.

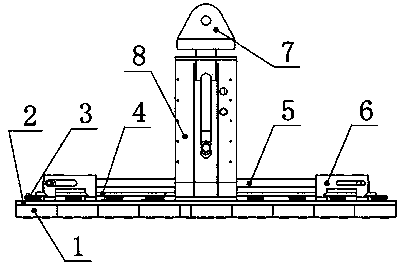

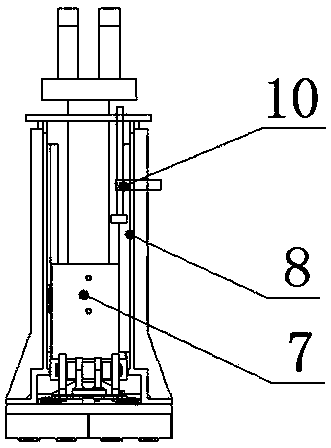

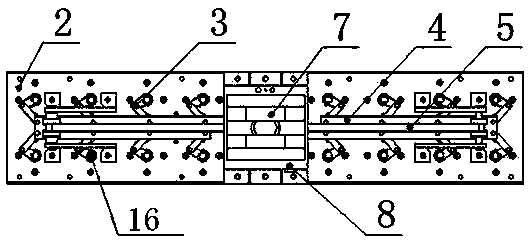

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the permanent magnet hanger of the present invention consists of a magnetic module 1, a top plate 2, a double connecting rod 3, a main connecting module 4, a pull rod 5, a main connecting module limiting unit 6, an up and down sliding module 7, and an up and down sliding module limiting unit 8 , self-locking unit 9, and magnetic modulation unit 10.

[0028] Depend on Figure 6 Schematic leverage 11, Figure 7 Schematic lever gear rack combination 12, Figure 8 Schematic connecting rod combination 13, Figure 9 The illustrated rack and pinion combination 14 and the pull rod 5 all belong to the linear motion conversion module, and their functions are to convert the up and down motion of the up and down sliding module 7 into the horizontal linear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com