Fiber preprocessing device

A pretreatment device and fiber technology, applied in the direction of raw material pretreatment, etc., can solve problems limited to mechanical refining, and achieve the effect of reducing dependence on chemicals, changing structural characteristics, and reducing use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

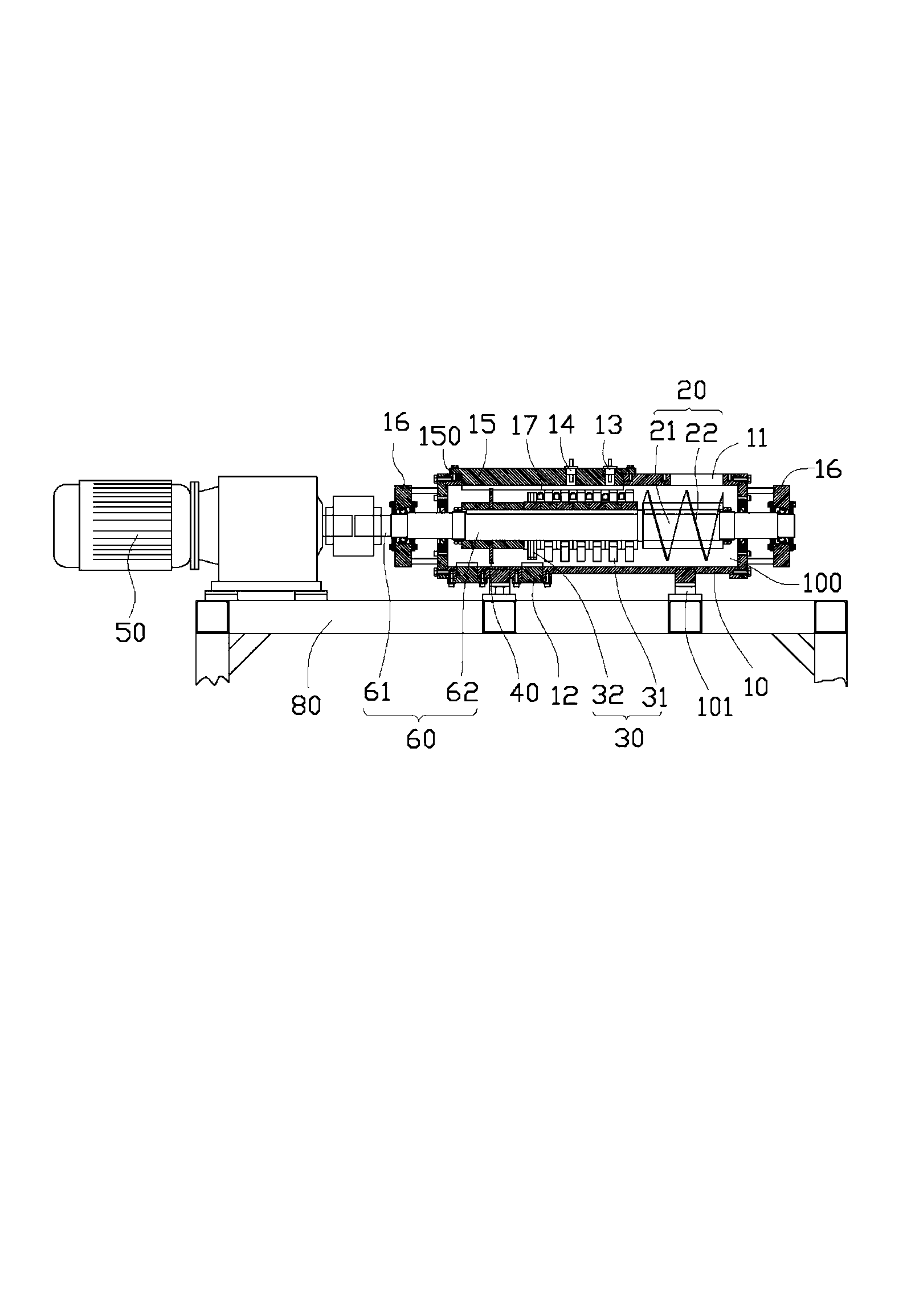

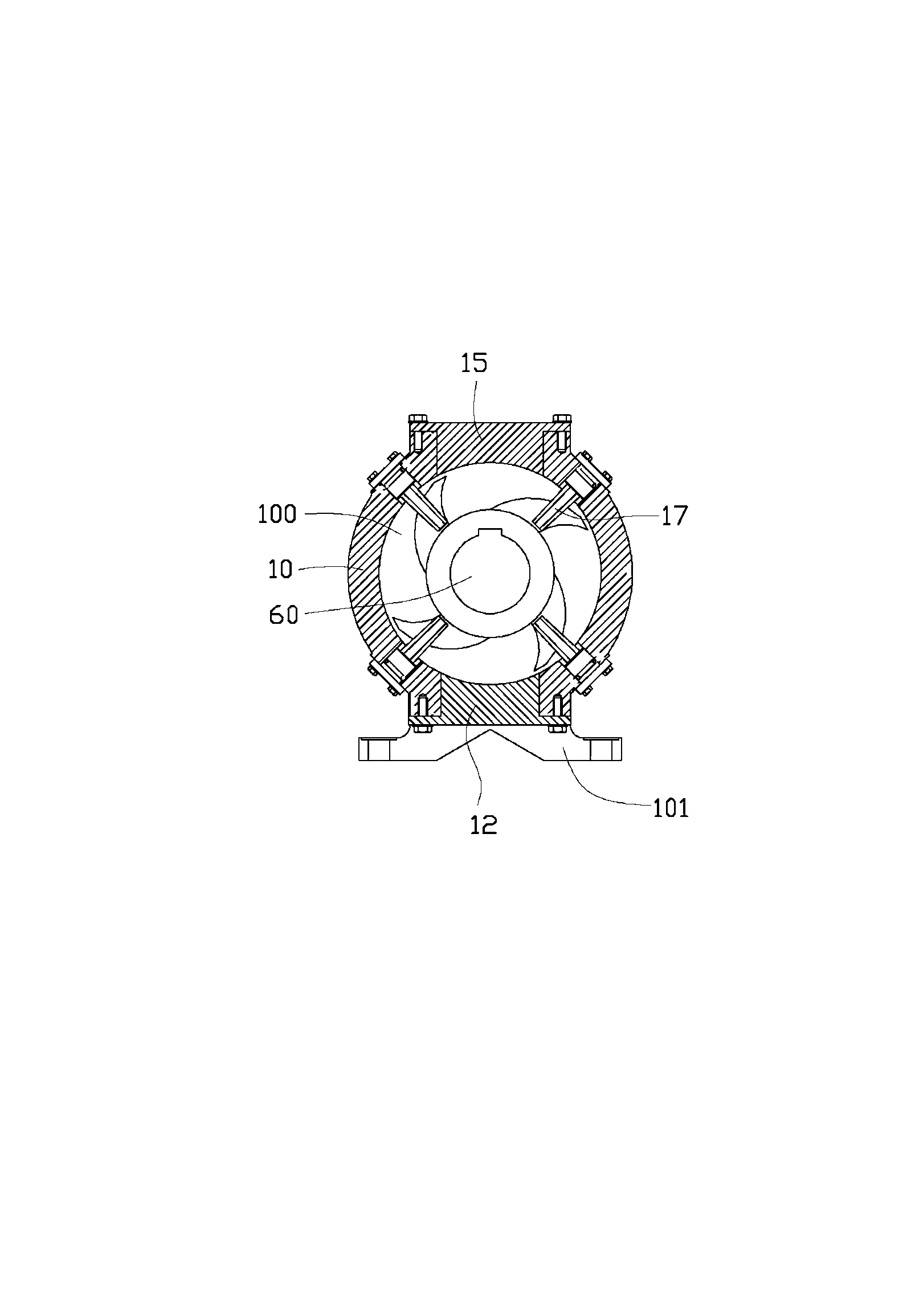

[0024] Please refer to figure 1 , The fiber pretreatment device according to one embodiment of the present invention includes a chamber body 10 , a screw mechanism 20 , a crimping mechanism 30 , a retaining plate 40 and a first power source 50 .

[0025] The cavity 10 is provided with a cavity 100, and the cavity 10 has a feed port 11 for the fiber raw materials used in papermaking to enter and a discharge valve 12 for the fibers to flow out. The discharge valve 12 is set with a predetermined pressure value. When the cavity When the pressure in the chamber 100 is greater than the predetermined pressure value, the discharge valve 12 is opened to allow the fibers to discharge.

[0026] The screw mechanism 20 is disposed in the chamber 100 and adjacent to the feeding port 11 , and is used to push the fiber entering from the feeding port 11 into the chamber 100 .

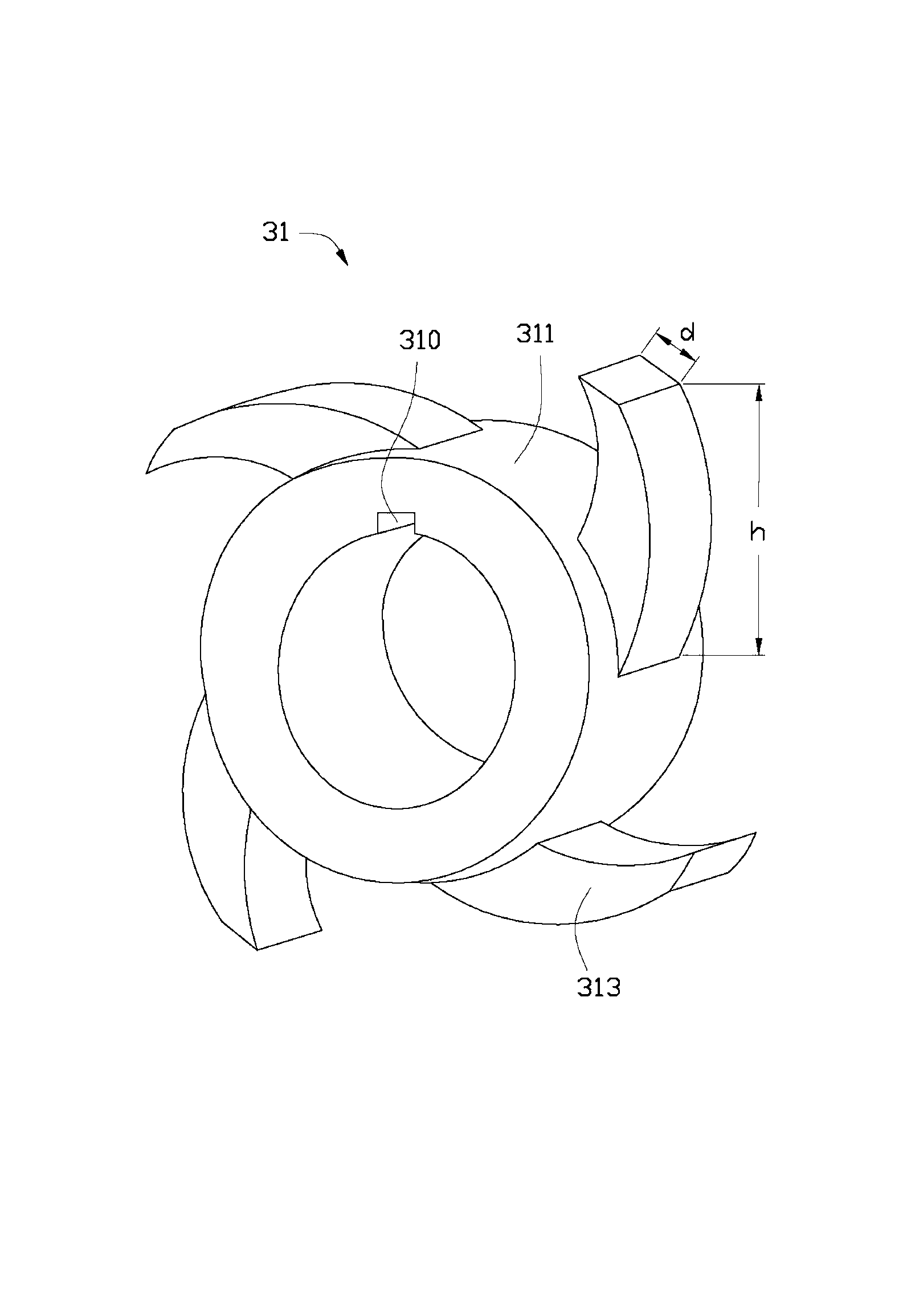

[0027] The crimping mechanism 30 is disposed in the chamber 100 and rubs, squeezes, and crimps the fiber propelled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com