Oscillating-buoy wave power device with hinged angle slide bar

A wave energy and float technology, which is applied in the field of floating wave energy power generation devices, can solve the problems of poor wave adaptability of floats, cable entanglement and damage, maintenance and repair difficulties, etc. The effect of drag and drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

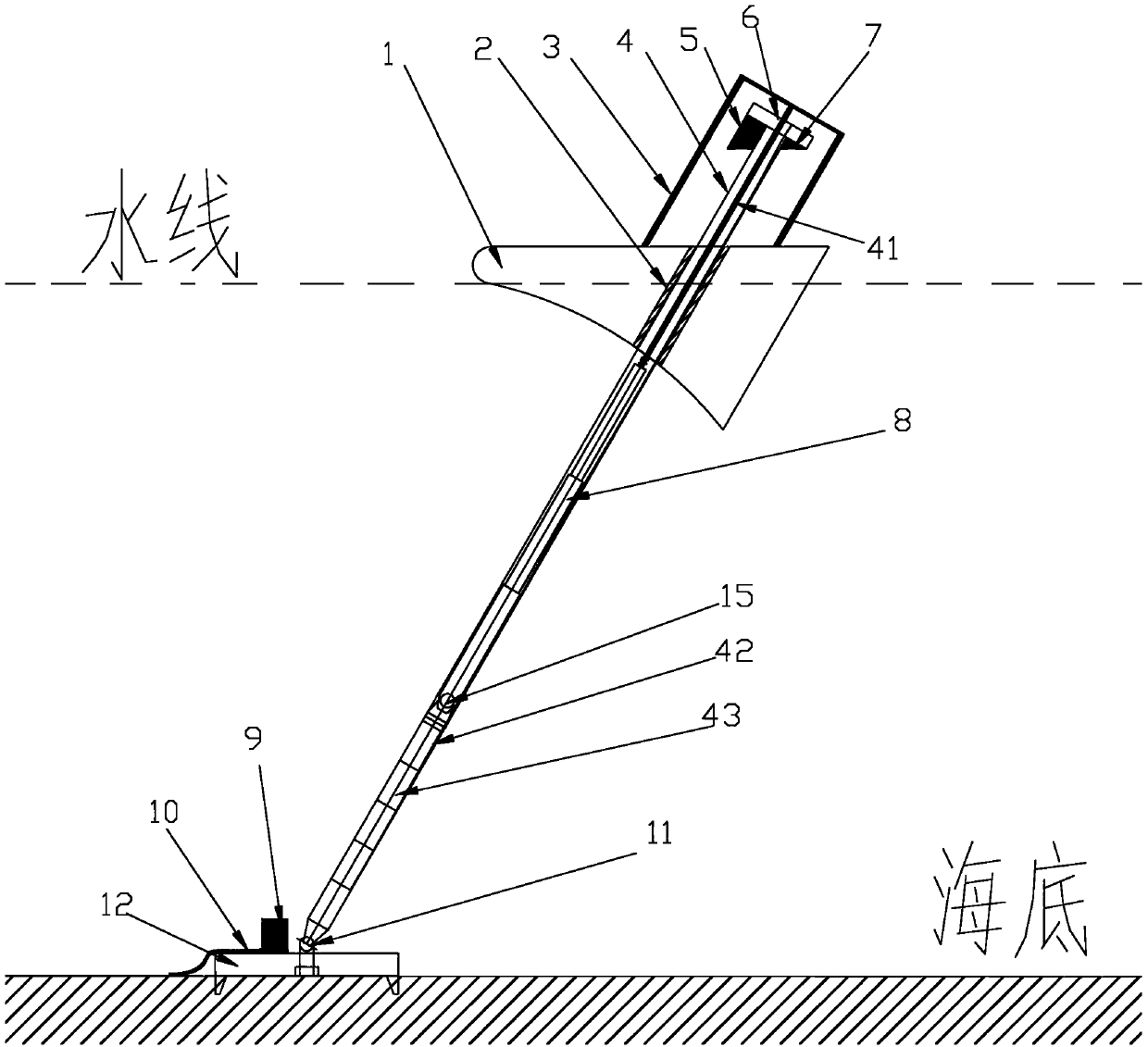

[0041] see figure 1 As shown, the wave energy device with oscillating buoy with hinged inclined slide bar includes an underwater appendage 12, a float 1, an energy conversion system 9 is arranged on the platform of the underwater appendage 12, and a linear bearing is installed on the central axis of the float 1 2. It also includes a sliding rod 4 with a hydraulic cylinder 8 inside. The sliding rod 4 forms an angle of less than 90 degrees with the horizontal line. The upper end of the sliding rod 4 is equipped with a gantry 3. The gantry 3 is connected with a pull rod 41, and the pull rod 41 extends into the slide. The rod 4 is connected with the rod end of the hydraulic cylinder 8, and the rodless end of the hydraulic cylinder 8 is installed on the platform vertical to the center line of the hydraulic cylinder 8 in the slide rod 4 through the hinge point 15, and the center line of the hydraulic cylinder 8 is connected to the center line of the slide rod 4 The center line coinc...

Embodiment 2

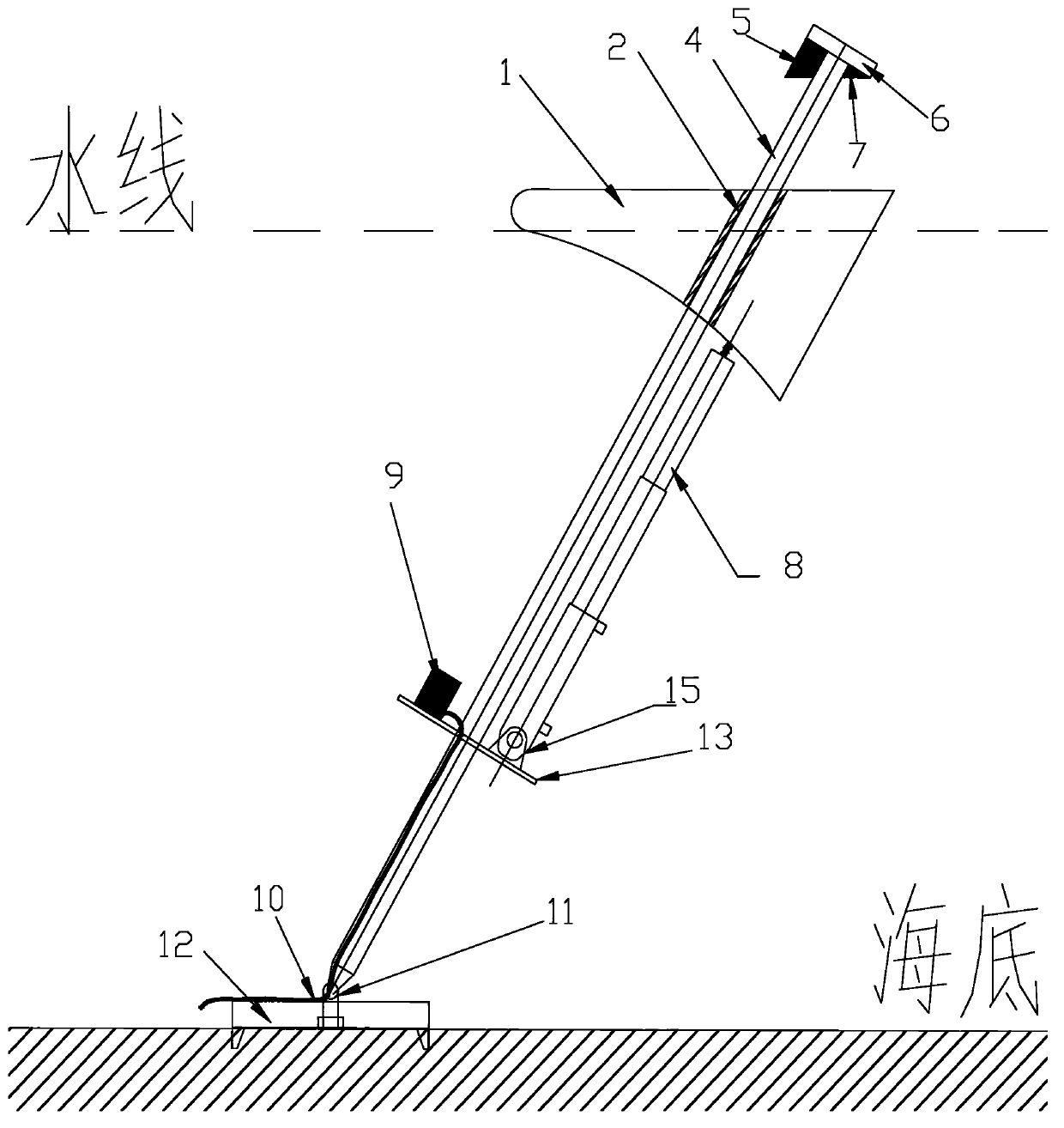

[0048] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that another linking method is adopted between the float 1 and the hydraulic cylinder 8, and the working principle is the same as that of the first embodiment. figure 2 Among them, a hydraulic cylinder 8 (which may be a multi-stage hydraulic cylinder) is installed on the platform 13 and beside the slide bar 4, the bottom end of the hydraulic cylinder 8 is connected to the platform 13 through a hinge point 15, and the top end of the hydraulic cylinder 8 is connected to the float 1 , the hydraulic cylinder 8 and the sliding rod 4 are in a parallel position, the hydraulic cylinder 8 is connected to the energy conversion system 9 through a hydraulic pipe; the energy conversion system 9 is connected to a cable 10, and the cable 10 falls directly from the underwater appendage 12 to the seabed and leads to the shore . With the axis of the slide bar 4 as the center, multiple hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com