Oil box position adjustment device

A technology for adjusting devices and oil boxes, which is applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., and can solve problems such as increasing the process, increasing production costs, and loss of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

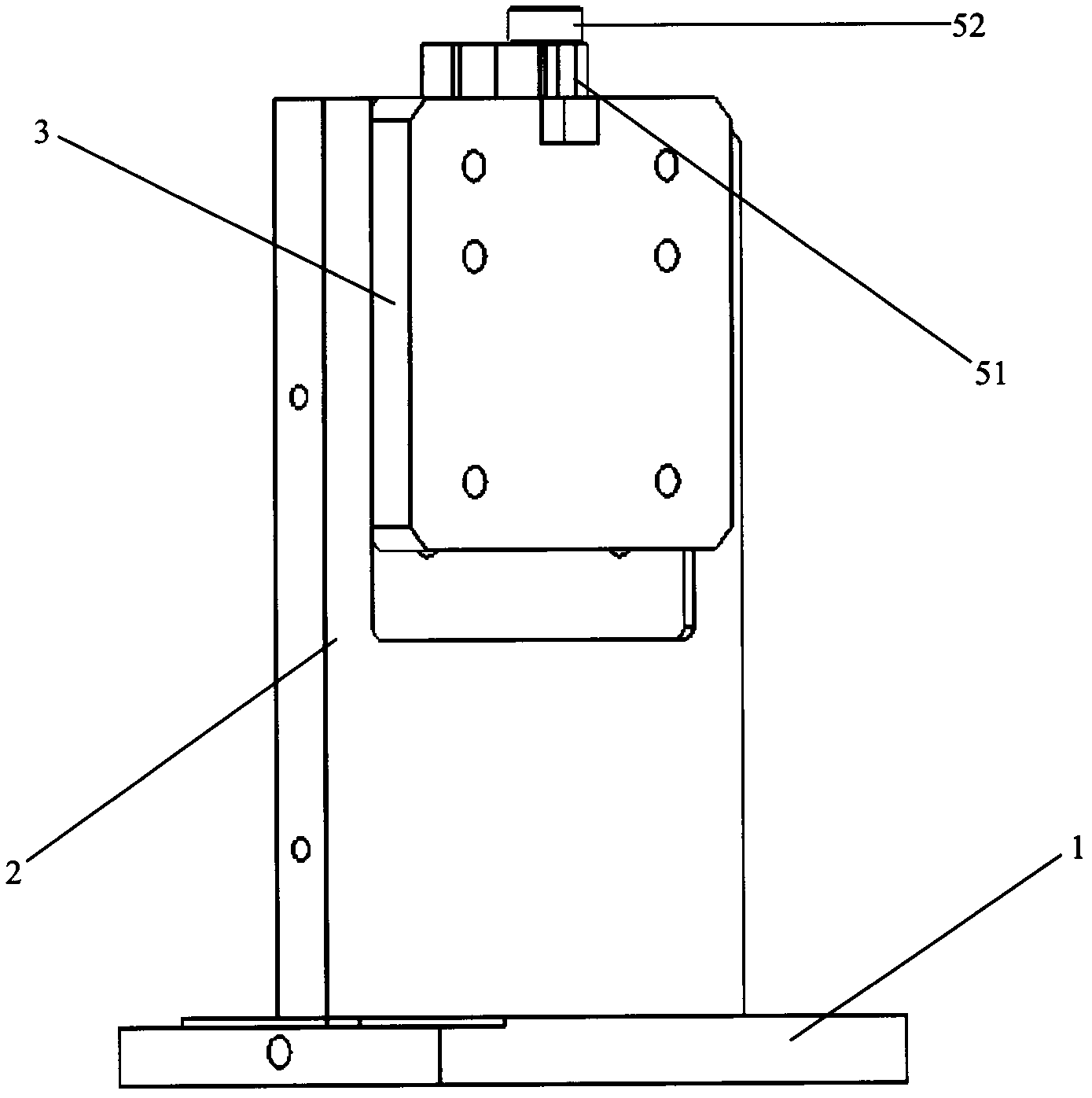

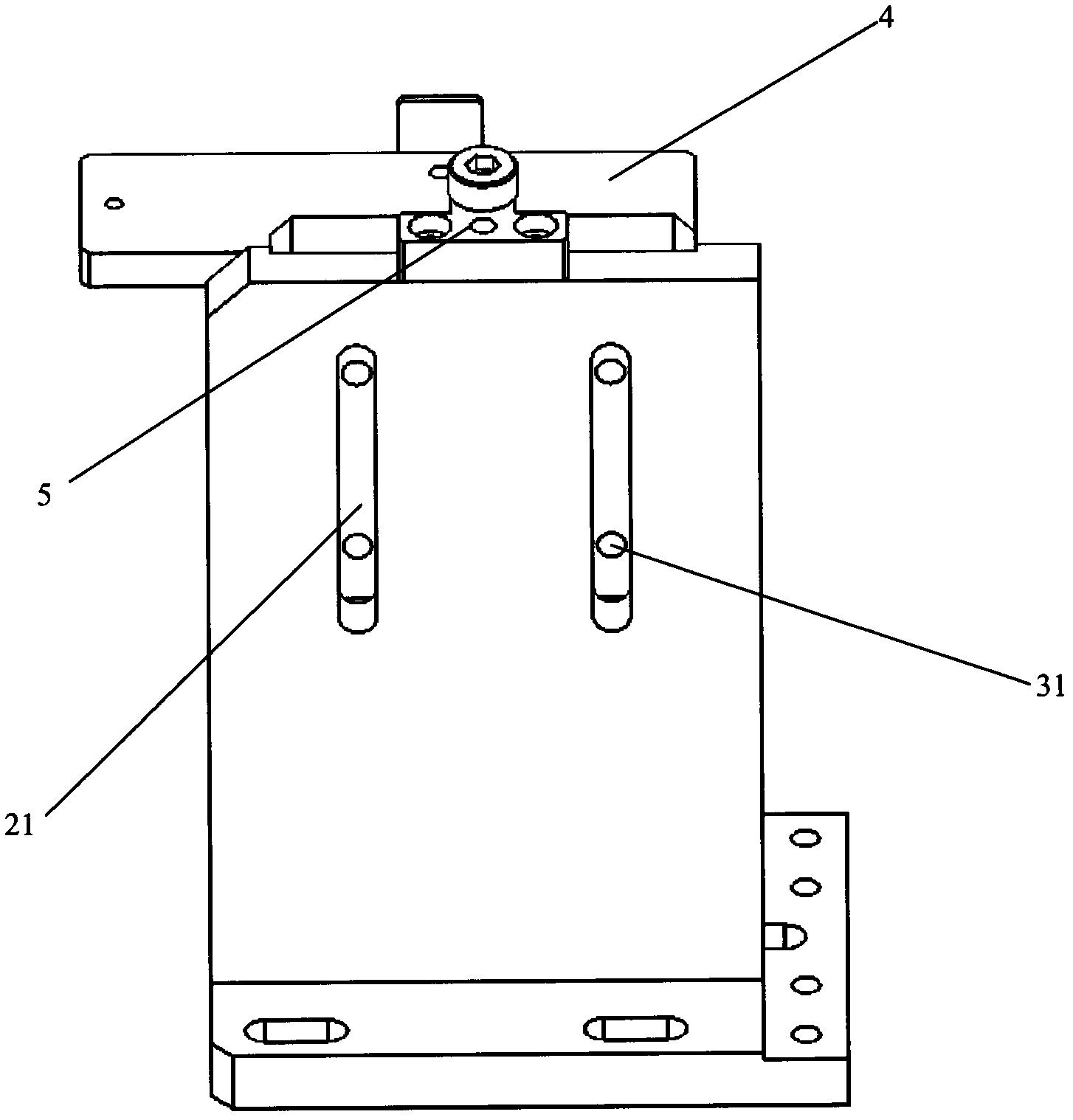

[0014] The present invention is further elaborated below by way of specific implementation: (as figure 1 and 2 )

[0015] This embodiment provides an oil box position adjustment device, which includes a base plate 1, a fixed plate 2 vertically arranged on the base plate, and at least one sliding groove 21 is recessed on the fixed plate, and the device also includes a sliding plate 3 One side of the sliding plate is arranged on one side of the fixing plate, and the sliding plate can slide back and forth along the sliding groove. The other side of the sliding plate is fixedly provided with an oil box supporting device 4 . A bolt structure 5 is provided at the top of the sliding plate, and the bolt structure includes nuts 51 and bolts 52 . A protruding post 31 is arranged on the sliding plate, and the protruding post protrudes into the sliding groove.

[0016] The specific adjustment method of the oil box position adjustment device provided in this embodiment is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com