Mercury-free clinical thermometer and production method thereof

The technology of a thermometer and its manufacturing method is applied in the field of medical equipment, which can solve the problems of temperature-sensing liquid falling back and inaccurate measurement readings, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

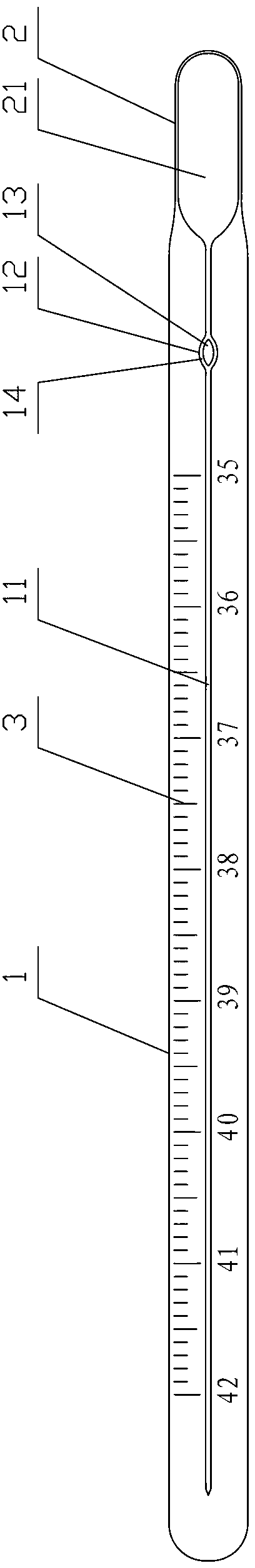

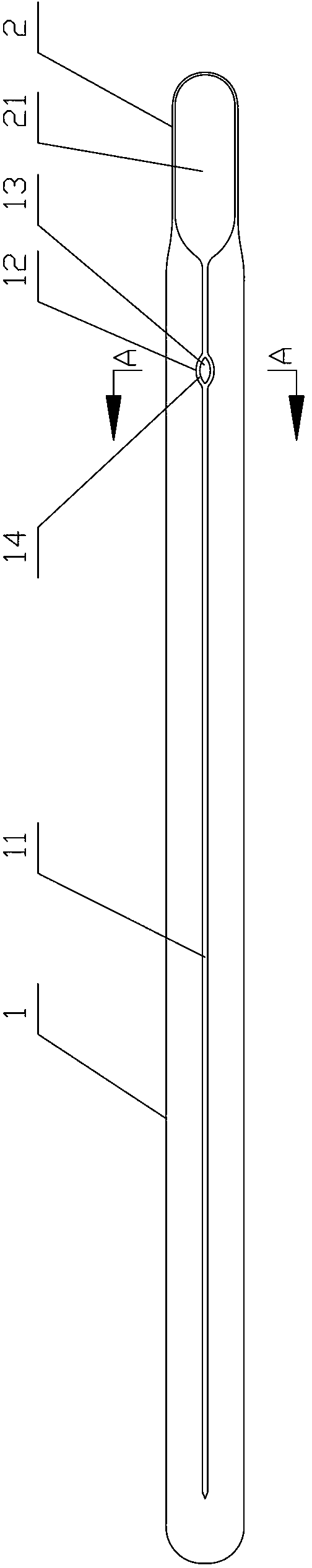

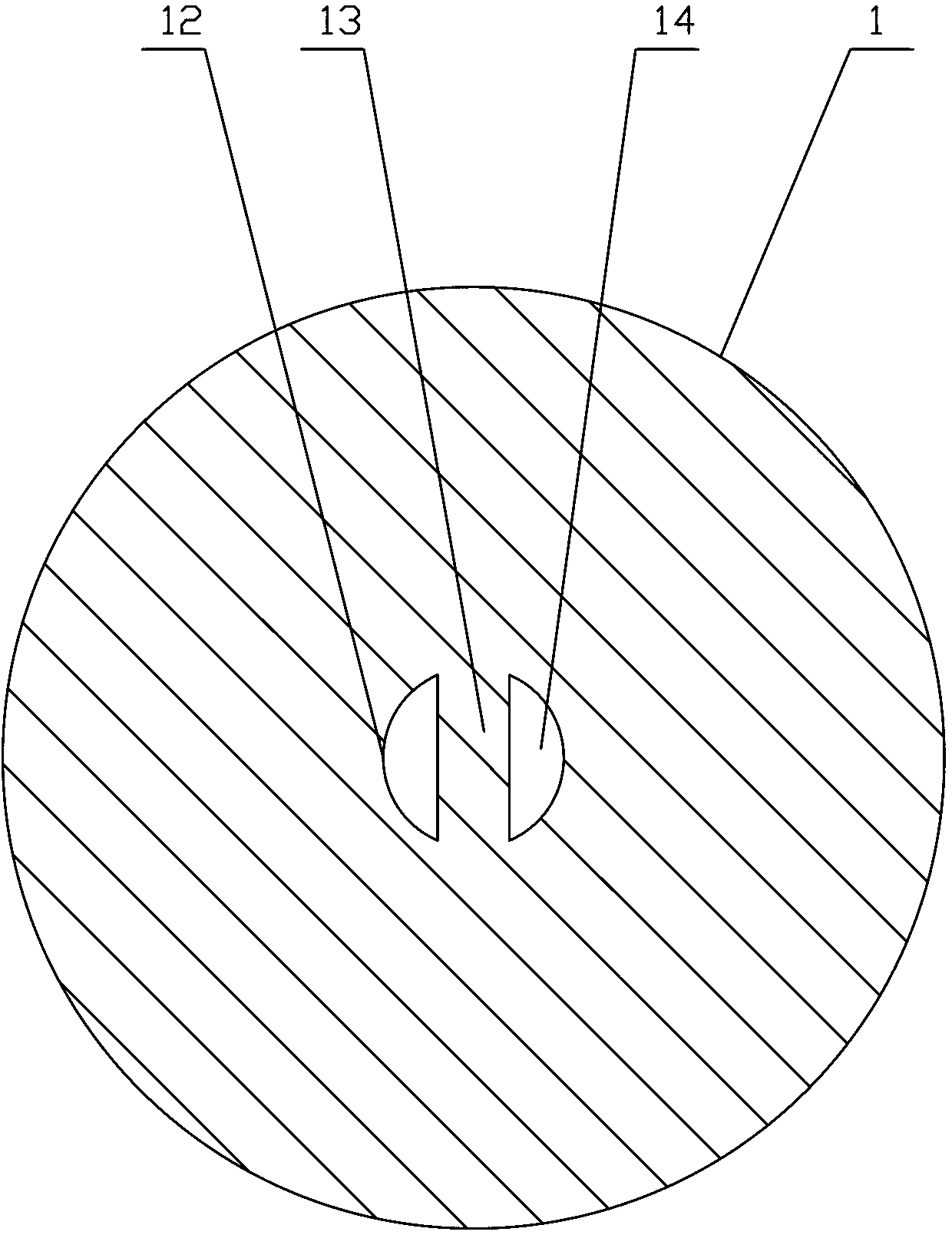

[0064] Such as Figure 1 to Figure 3 As shown, the mercury-free thermometer provided in this embodiment includes a tube body 1 and a temperature-sensitive bulb 2. Capillary holes 11 are formed inside the tube body 1 along the axial direction, and a cavity 21 is formed inside the temperature-sensitive bulb 2; One end of the tube body 1 is connected to the temperature-sensitive bubble 2, and the capillary hole 11 is connected to the cavity 21; a throat bubble 12 is also formed on the capillary hole 11; A flow channel 14 is formed between the outer wall of the dot protrusion 13; the flow area of the flow channel 14 is smaller than the flow area of the capillary hole 11; the temperature-sensing bubble 2 and the capillary hole 11 are provided with a temperature-sensing liquid.

[0065] when using it:

[0066] The temperature-sensing bubble 2 is used to contact the human body, so that the temperature-sensing liquid in the cavity 21 will expand after being heated, and the temper...

Embodiment 2

[0083] Such as Figure 4 As shown, the method for manufacturing a mercury-free thermometer provided in this embodiment may specifically include the following steps:

[0084] Step 101, forming a tightening port by melting one end of the tube material;

[0085] Step 102, heating the material of the pipe body and forming throat bubbles on the capillary pores;

[0086] Step 103, welding the tightening port to one end of the temperature-sensitive bulb material;

[0087] Step 104, heating the material of the pipe body, and forming a raised spot in the throat bubble;

[0088] Step 105, heat and seal the temperature-sensitive foam tube material, and make a temperature-sensitive foam to obtain a semi-finished product;

[0089] Step 106, pouring the temperature-sensitive liquid into the capillary pores and cavities inside the semi-finished product;

[0090] Step 107, refilling the temperature-sensing liquid, and burning out the capillary pores in the pipe material;

[0091] Step 10...

Embodiment 3

[0115] Such as Figure 15 As shown, the method for manufacturing a mercury-free thermometer provided in this embodiment may specifically include the following steps:

[0116] Step 201, melting one end of the pipe material to form a tightening port;

[0117] Step 202, heating the material of the pipe body and forming throat bubbles on the capillary pores;

[0118] Step 203, welding the tightening port to one end of the temperature-sensitive bulb material;

[0119] Step 204, heating the material of the pipe body, and forming a raised spot in the throat bubble;

[0120] Step 205, heat and seal the temperature-sensitive foam tube material, and make a temperature-sensitive foam to obtain a semi-finished product;

[0121] Step 206, pouring the temperature-sensitive liquid into the capillary pores and cavities inside the semi-finished product;

[0122] Step 207, refilling the temperature-sensing liquid, and burning out the capillary pores in the pipe material;

[0123] Step 208,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com