Special wire clamp for cable

A cable and clamp technology, which is applied in the field of special cable clamps, can solve the problems of cumbersome installation, high price, damage to the main and branch cables, etc., and achieve the effect of good integrity, scientific force, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

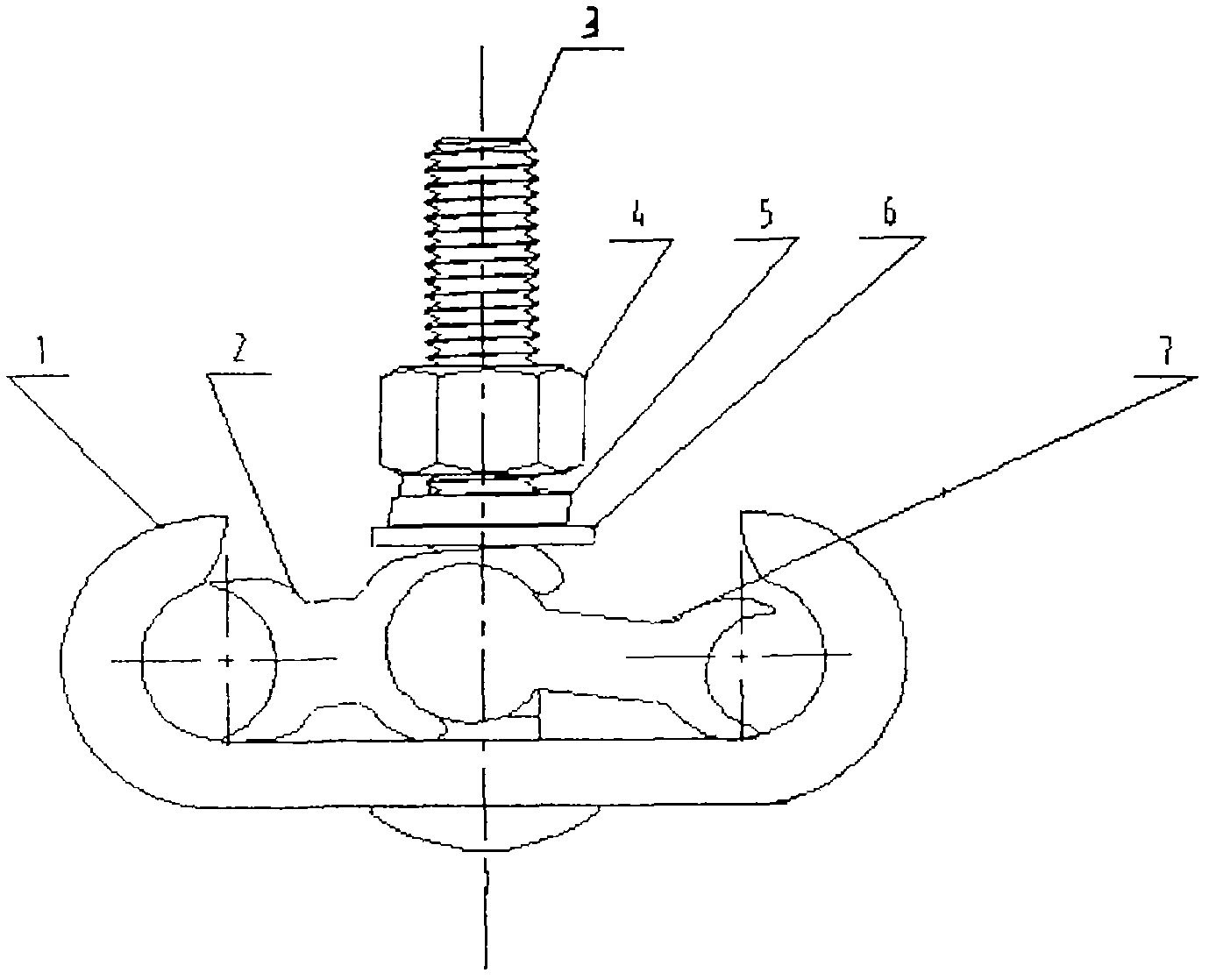

[0007] As shown in the accompanying drawings, the schematic diagram of the cable clamp of the present invention, as shown in the figure, the cable clamp of the present invention includes a base 1, a crimping device and a fastening device, wherein the base 1 is C-shaped, and the crimping device is The hinged blocks 2, 7 and the hinged blocks 2, 7 are placed in the C-shaped base 1, the hinged block is composed of a main hinged part 2 and a secondary hinged part 7, both ends of the main hinged part 2 are concave arcs, and the secondary hinged part Part 7 is a convex cylinder at one end and a concave arc at the other end. One end of the main hinge part 2 cooperates with one end of the C-shaped base to form a crimping groove for the main cable. Cooperate with each other to form a hinged connection, and the other end of the secondary hinge part is concave to cooperate with the other end of the C-shaped base to form a crimping groove for the branch cable. The radius of the concave ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com