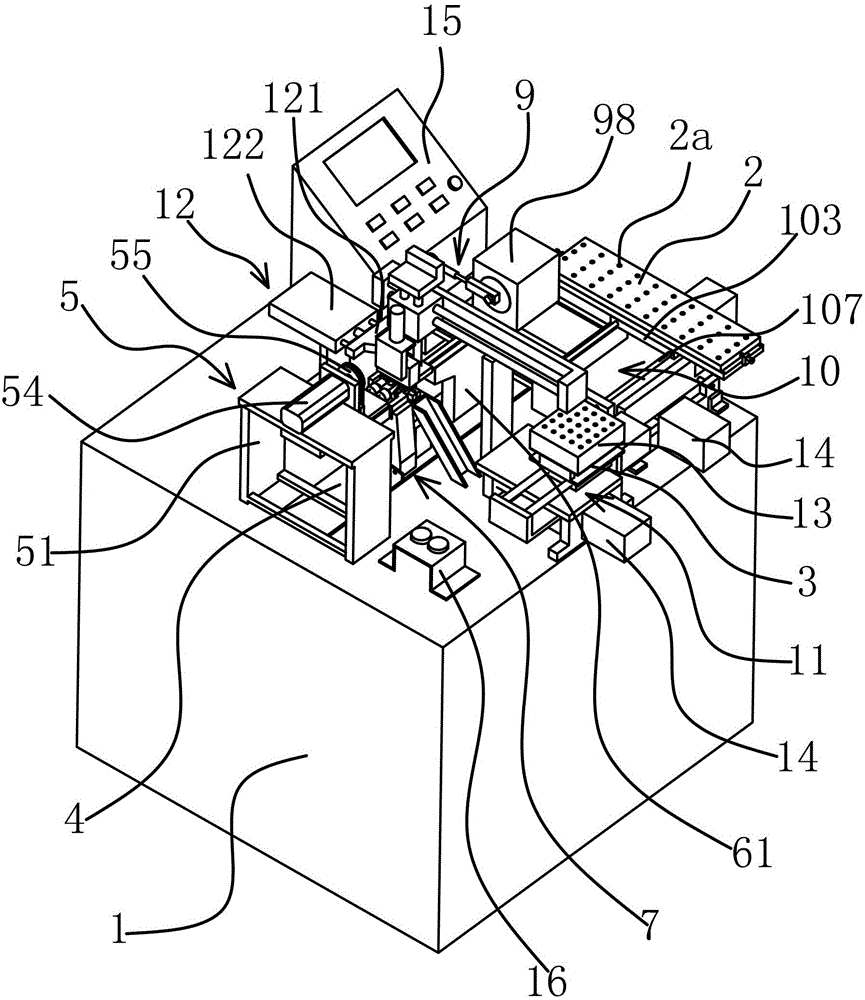

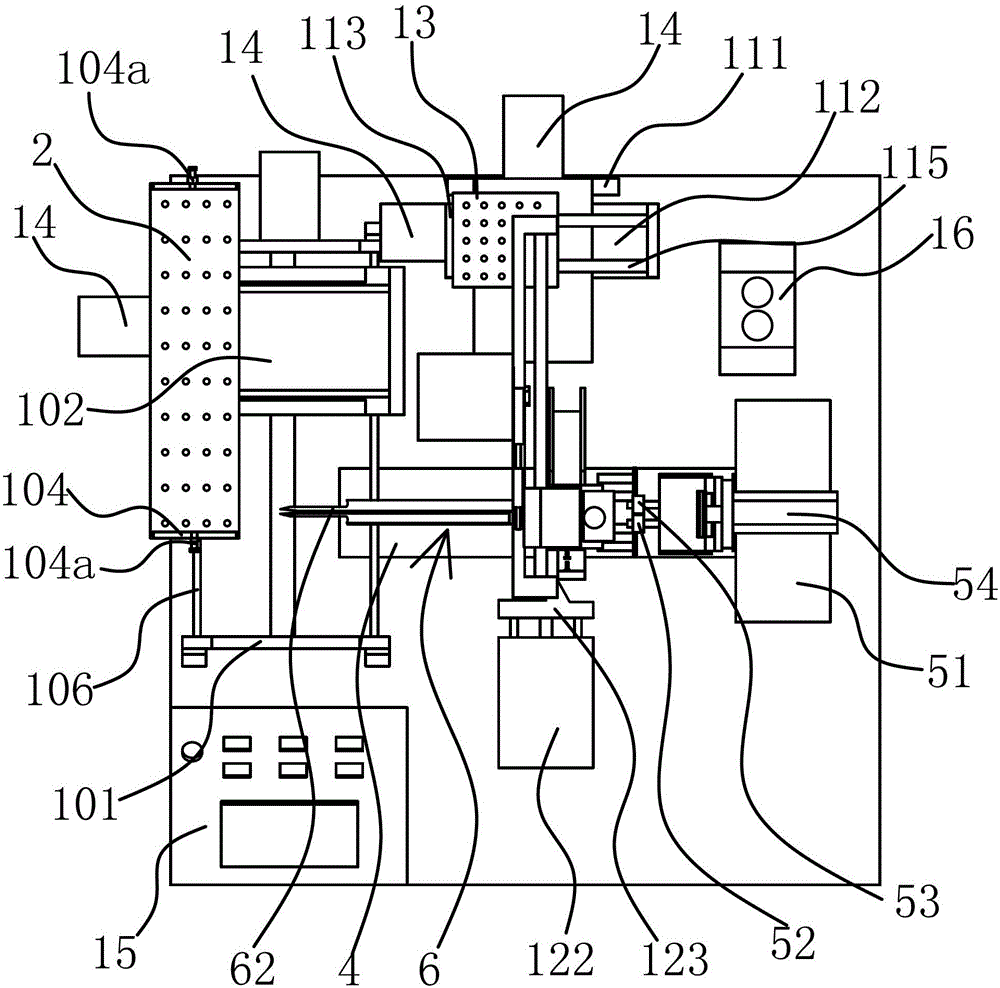

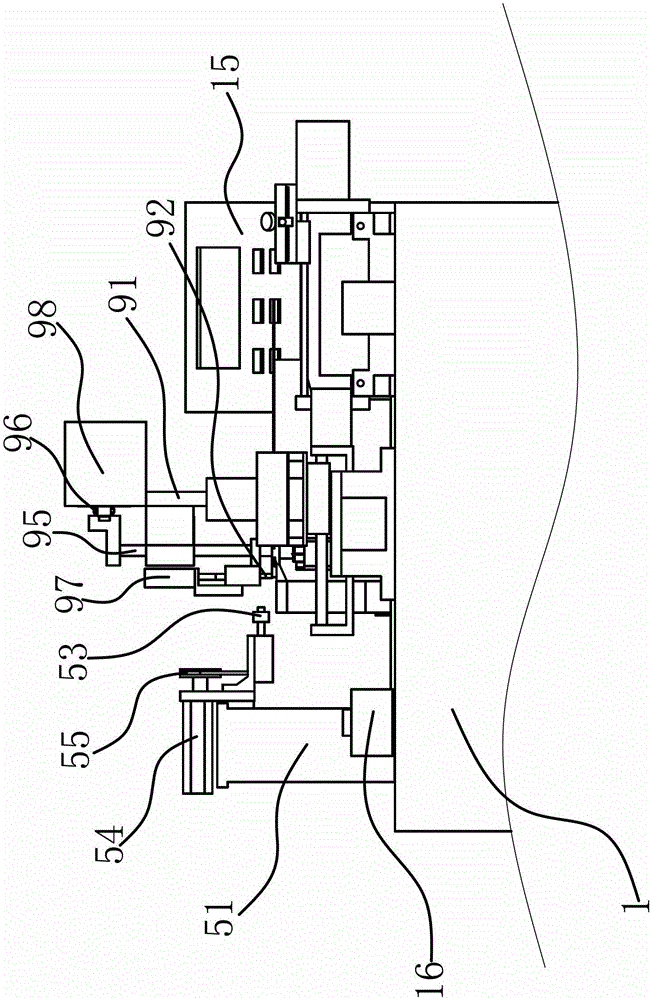

A crystal oscillator automatic frequency modulation machine

An automatic frequency modulation and crystal oscillator technology, applied in electrical components, impedance networks, etc., can solve the problems of low efficiency of manual processing, unfavorable production workshop environment, and high requirements for the number of workers, to save manual operations, reduce production costs, and achieve frequency modulation accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0049] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1. The difference is that in this embodiment, a computer is used to control the crystal oscillator automatic frequency adjustment machine, or PLC and other control components are used to realize the automatic or automatic frequency adjustment of the crystal oscillator. Semi-automatic FM processing.

Embodiment 3

[0051] The technical solution in this embodiment is basically the same as that in Embodiment 1 and Embodiment 2, the difference is that in this embodiment, grinding wheel 1 52 and grinding wheel 2 53 are driven by friction wheels to realize synchronous rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com