Brake system having a connection, which can be switched by means of a brake pedal, for decoupling a drive device from a piston-cylinder unit

A technology of braking equipment and driving devices, applied in the direction of braking action starting devices, braking transmission devices, hydraulic braking transmission devices, etc., can solve the problems of mechanical structure and manufacturing costs of clutches or connecting parts, and achieve improved diagnosis and feasibility The effect of high reliability, low consumption and high fail-safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

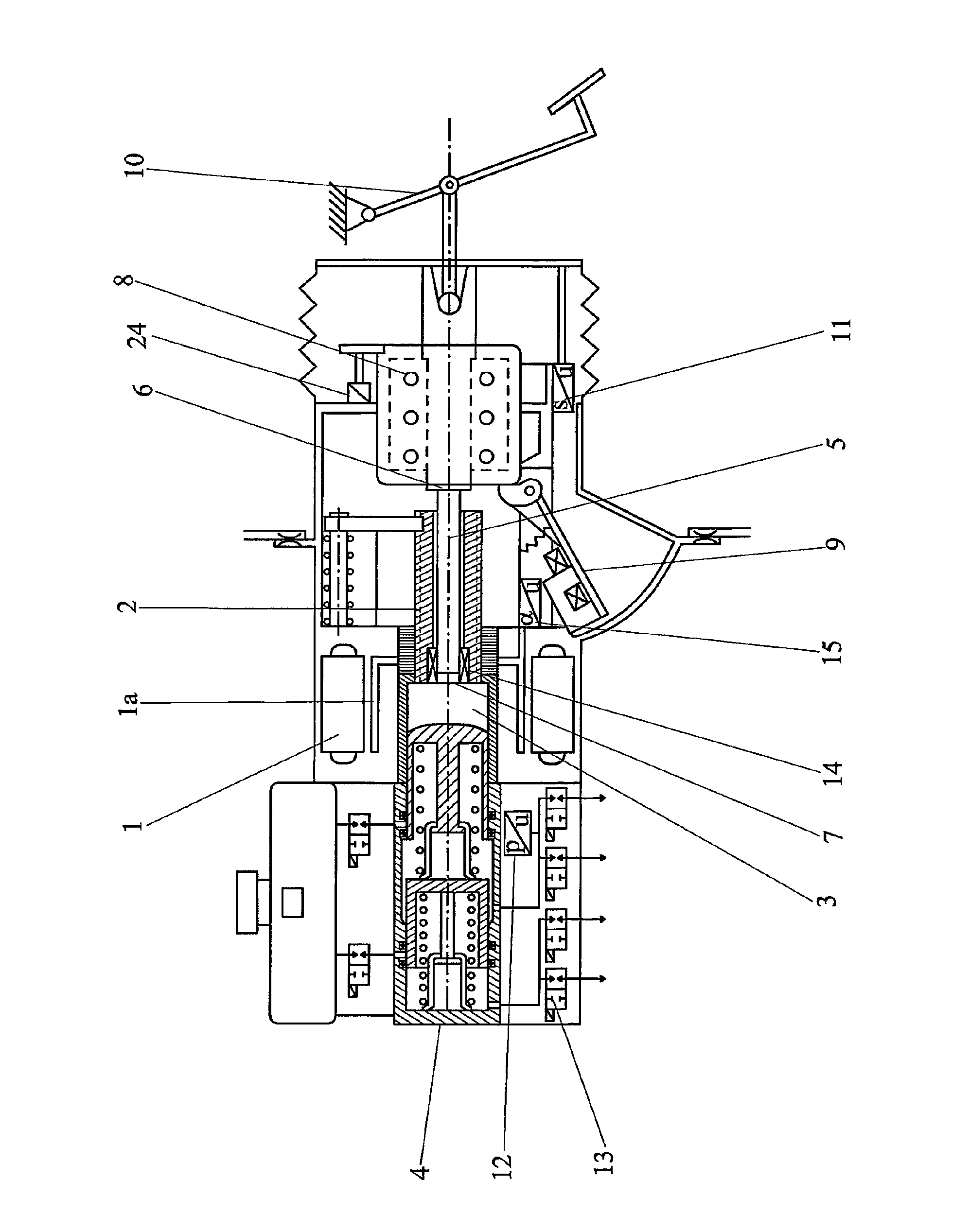

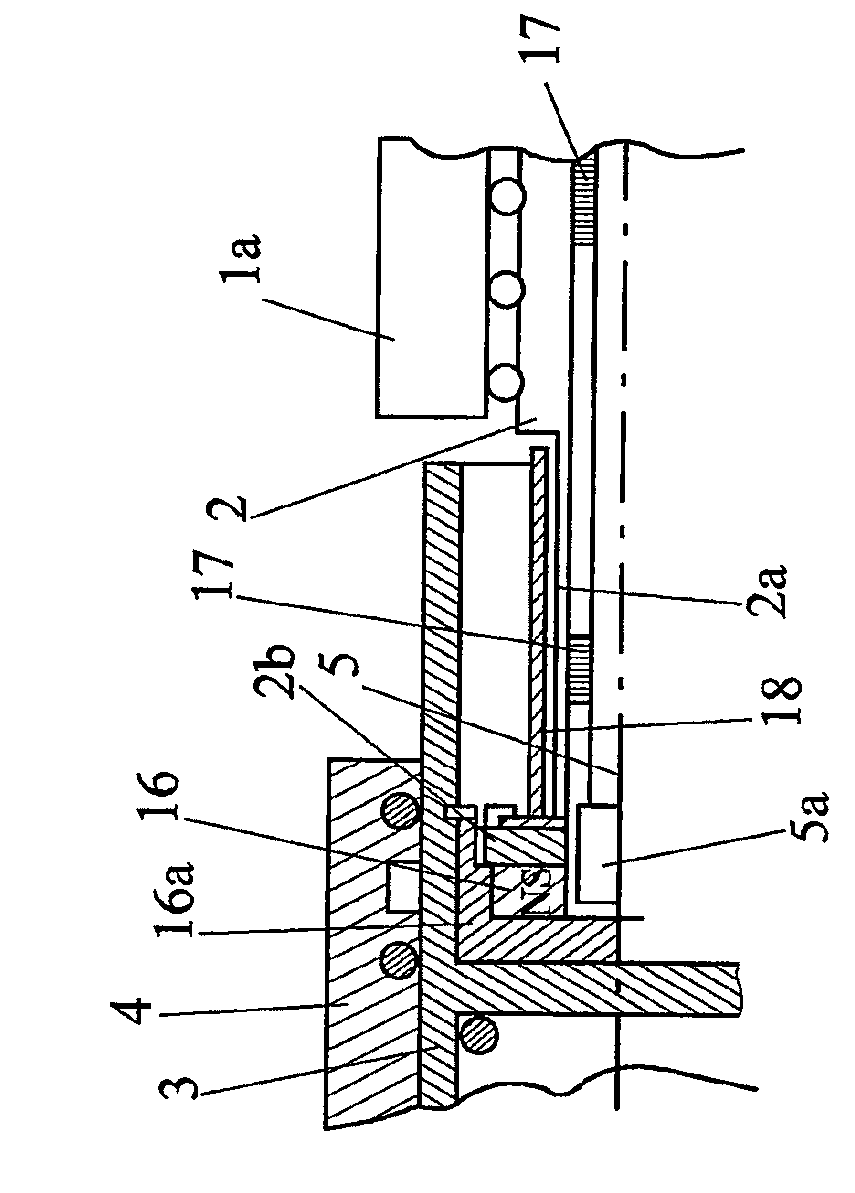

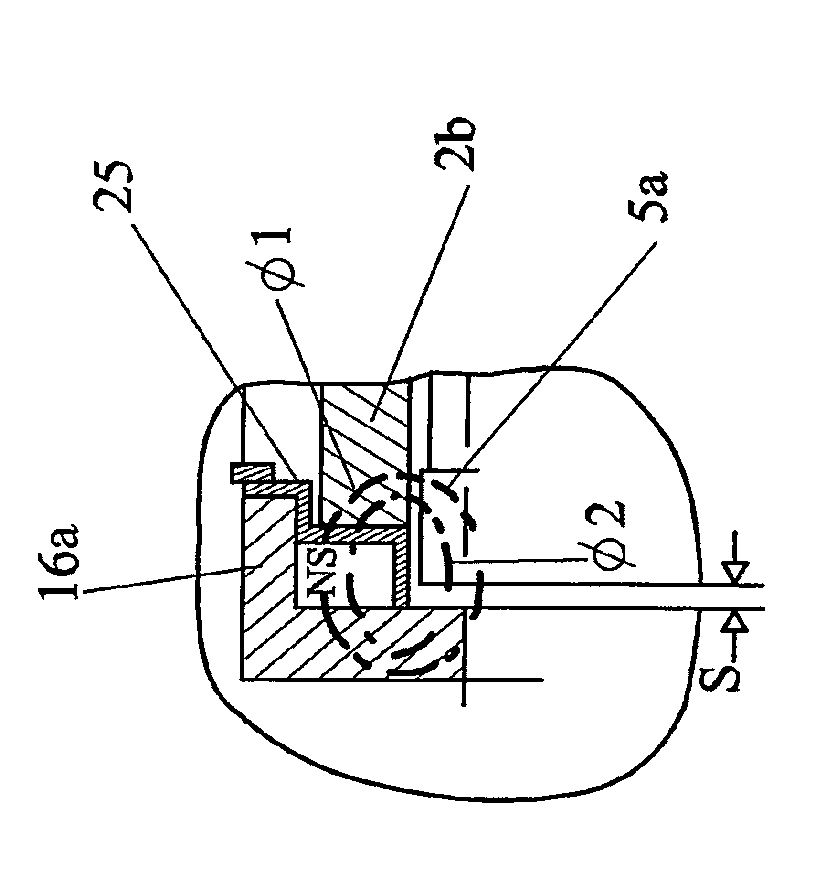

[0029] figure 1 An integrated brake booster with an electric motor 1 , which drives a screw 2 , with a corresponding rotor 1 a and a screw nut is shown. The pushrod piston 3 is movably arranged in the tandem master cylinder 4 . Furthermore, the clutch 14 acts between the push rod piston 3 and the screw 2 only when the electric motor 1 or the drive is functioning properly. The clutch 14 itself and the connection between the push rod piston 3, the screw rod 2 and the pedal push rod 5 that is disconnected or disconnects the clutch 14 in the event of a failure figure 1 is shown only schematically, and by means of Figures 2 to 4 Elaborate.

[0030] In normal operation, actuation of the brake pedal 10 is detected via the pedal travel sensor 11 and the pushrod piston 3 is actuated via the electric motor 1 and the screw 5 moved by the rotor of said electric motor for pressure buildup and pressure drop. The function of pressure build-up and pressure drop is already sufficiently kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com