Five-freedom adjustable pipeline butt joint tooling

A technology with a degree of freedom and pipe materials, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems affecting welding quality, uneven wall thickness, and poor straightness of small-diameter steel pipes, so as to improve operating efficiency and improve nozzle The effect of combining quality and ensuring the quality of weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

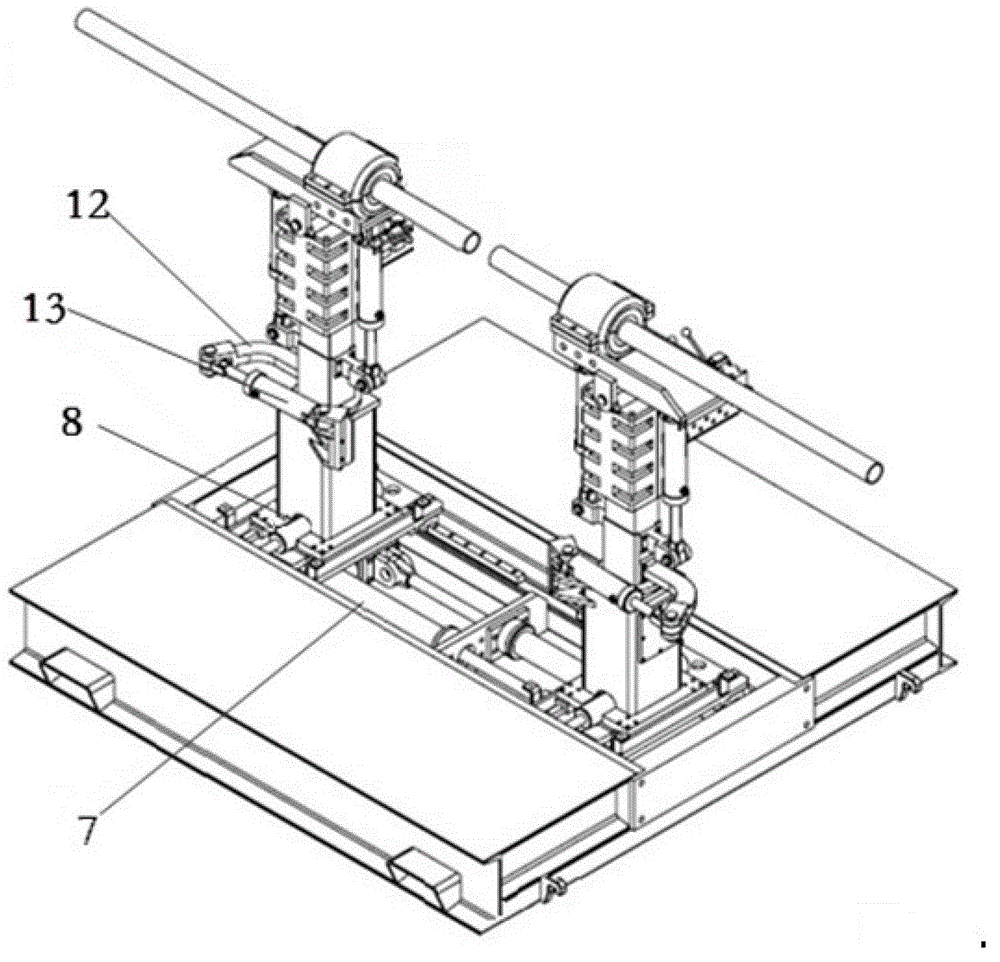

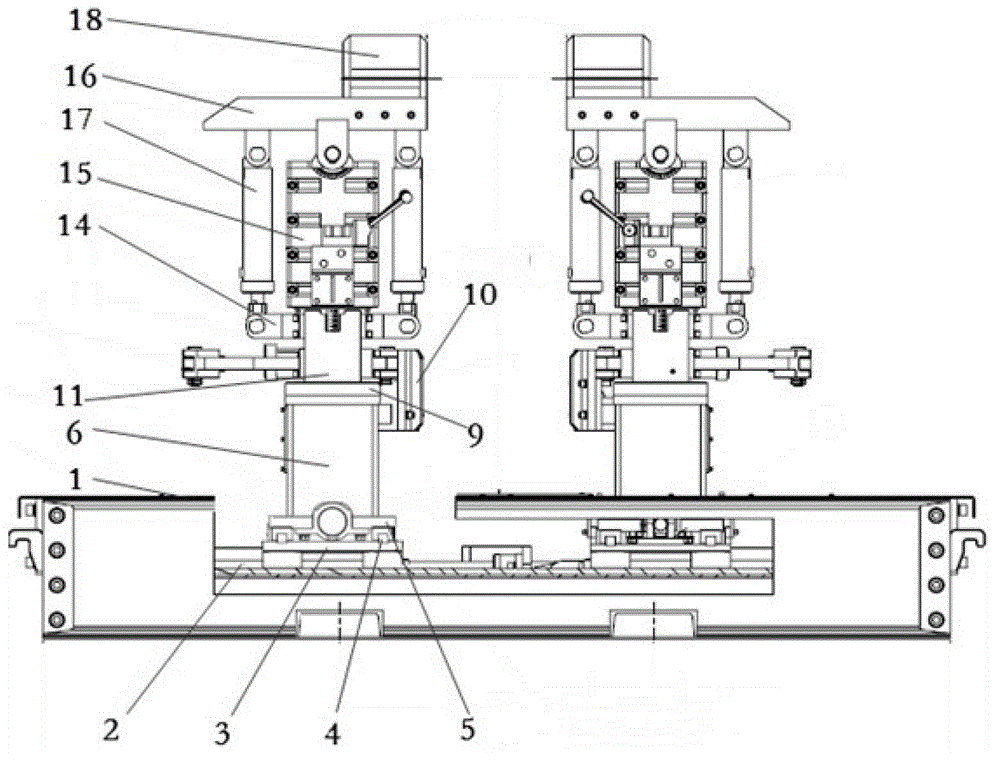

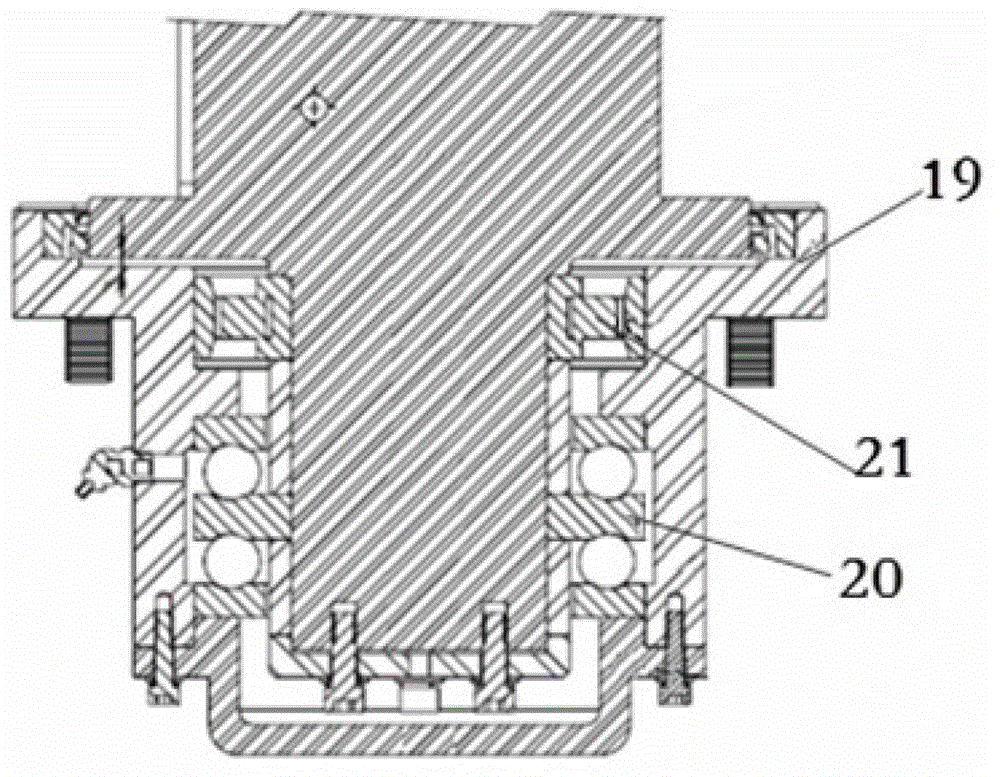

[0014] Attached below figure 1 , 2 , 3, 4, 5 describe an embodiment of the present invention.

[0015] A five-degree-of-freedom adjustable pipe butt joint tooling has a base 1, and two parallel X-direction slide rails 2 are arranged on the base 1, and two left and right X-direction slides 3 are arranged on two parallel X-direction slide rails through sliders. On the slide rail 2, two parallel Z-direction slide rails 4 are arranged on the left and right X-direction slide plates 3, and the left and right Z-direction slide plates 5 are arranged on the two parallel Z-direction slide rails 4 through sliders and respectively Located above the left and right X-direction slides 3; the left and right column bases 6 are respectively fixed on the left and right Z-direction slides 5, and the left and right X-direction slides 3 pass through the two X-direction drive cylinders set on the base 1 respectively 7 drive, the two left and right Z-direction slides 5 are respectively driven by tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com