Press-mounting, locking and balancing device for blanking cap and press-mounting machine for blanking cap

A technology of balancing devices and blocking caps, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult implementation, complicated equipment, and inability to achieve absolute synchronization in the press-fitting process, and achieve good versatility and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

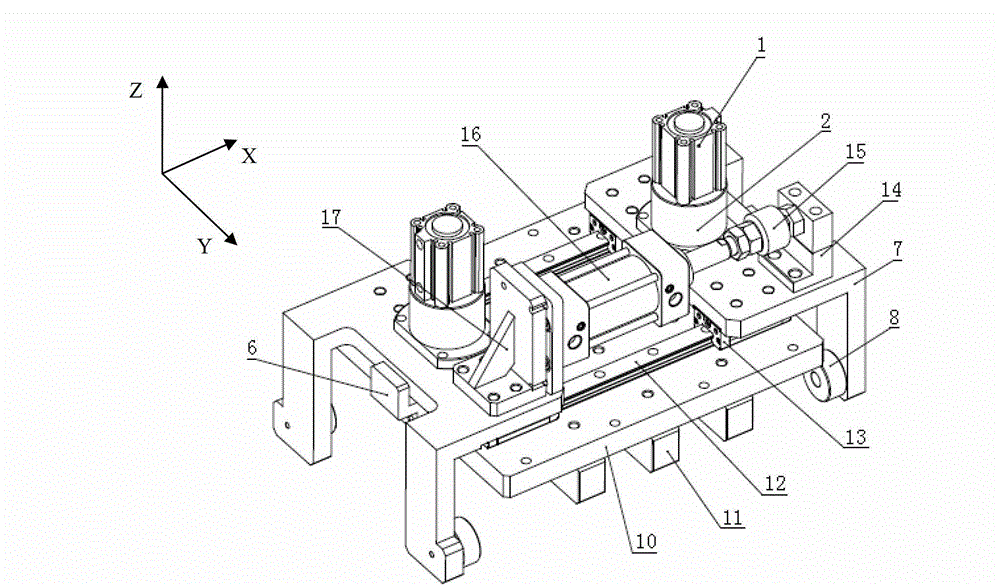

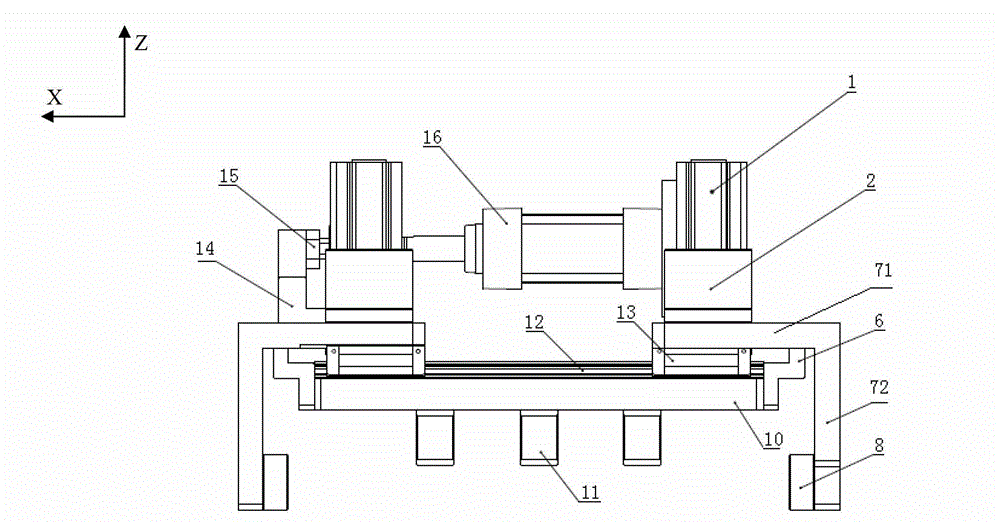

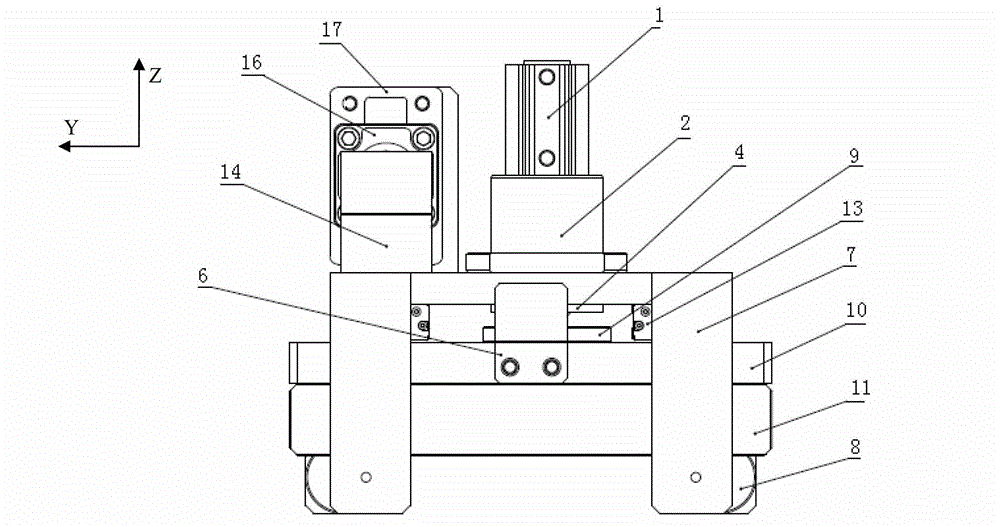

[0036] In the following description of the embodiments of the present invention in conjunction with the accompanying drawings, it is defined that the positive direction of the Z-axis is up, the positive direction of the X-axis is right, and the positive direction of the Y-axis is front.

[0037] combine figure 1 , figure 2 , image 3 and Figure 4 . The bottom plate 10 is the connection supporting mechanism of the whole device. A strip-shaped stopper 11 is installed below the bottom plate 10 . Two slide rails 12 are installed above the bottom plate 10 . The clamping frame 7 is divided into two parts, one part is the horizontal part 71 of the clamping frame on which the slider 13 is installed underneath, and the other part extends from the edge of the horizontal part 71 of the clamping frame toward the bottom of the bottom plate (ie, the negative direction of the Z axis). There are two clip arms 72, and the two clip arms 72 are spaced apart from each other. On the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com