Taper spline connecting device capable of preventing cutting disc of ditcher from loosening

A coupling device and ditching machine technology, which is applied in the direction of key connection, excavation/covering trenches, connection components, etc., can solve problems such as looseness, difficult disassembly of cutter heads, loose nuts, etc., to increase friction coefficient, disassembly and assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

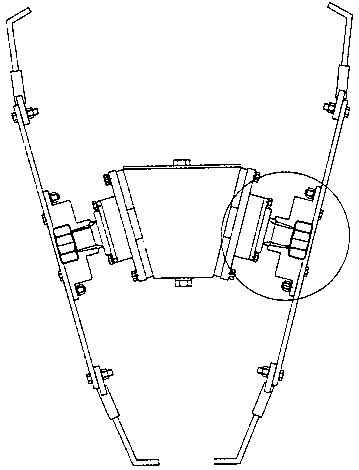

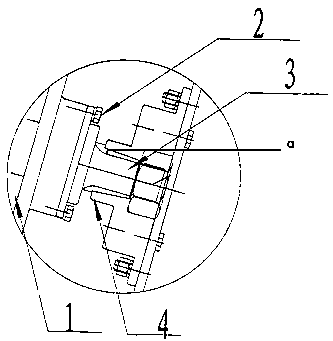

[0015] like figure 1 , figure 2 The shown taper spline coupling device for preventing the loosening of the cutter head of the ditching machine includes the cutter head shaft bearing seat 1, the nut 2, the cutter head spline shaft 3 and the worm spline sleeve 4, and the cutter head spline shaft 3 passes through the nut 2 is fastened on the cutter head shaft bearing seat 1, and the wheel spline sleeve 4 is installed on the periphery of the cutter head spline shaft. The cutter head spline shaft and the worm spline sleeve are set to match the taper α to 0.5 degrees, which is used to increase the friction coefficient of the mating surface between the cutter head spline shaft 3 and the worm spline sleeve 4. When the trencher is working, the The connection between the spline of the cutterhead shaft and the vortex spline of the cutterhead wheel will not be loose, so the spline part will not be deformed due to impact due to looseness, and the spline will not damage the function of ur...

Embodiment 2

[0017] The taper spline coupling device for preventing the loosening of the ditching machine cutter head in this implementation includes a cutter head shaft bearing seat 1, a nut 2, a cutter head spline shaft 3 and a worm spline sleeve 4, and the cutter head spline shaft 3 passes through the nut. 2 is fastened on the cutter head shaft bearing seat 1, and the wheel spline sleeve 4 is installed on the periphery of the cutter head spline shaft. The cutter head spline shaft and the worm spline sleeve are set to match the taper α to 7 degrees, which is used to increase the friction coefficient of the mating surface between the cutter head spline shaft 3 and the worm spline sleeve 4. When the trencher is working, the The connection between the spline of the cutterhead shaft and the vortex spline of the cutterhead wheel will not be loose, so the spline part will not be deformed due to impact due to looseness, and the spline will not damage the function of urban power transmission prem...

Embodiment 3

[0019] The taper spline coupling device for preventing the cutter head of the ditching machine from loosening in this embodiment includes a cutter head shaft bearing seat 1, a nut 2, a cutter head spline shaft 3 and a worm spline sleeve 4, and the cutter head spline shaft 3 passes through the The nut 2 is tightly connected to the cutter head shaft bearing seat 1, and the wheel spline sleeve 4 is installed on the periphery of the cutter head spline shaft. The cutter head spline shaft and the worm spline sleeve are set to match the taper α to 4 degrees, which is used to increase the friction coefficient of the mating surface between the cutter head spline shaft 3 and the worm spline sleeve 4. When the trencher is working, the The connection between the spline of the cutterhead shaft and the vortex spline of the cutterhead wheel will not be loose, so the spline part will not be deformed due to impact due to looseness, and the spline will not damage the function of urban power tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com