Hub drilling device combination

A technology for drilling devices and hubs, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as low production efficiency, low product qualification rate, and difficult processing, and achieve quality improvement , Improve the pass rate, reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

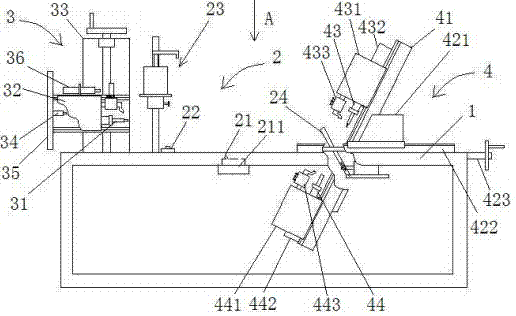

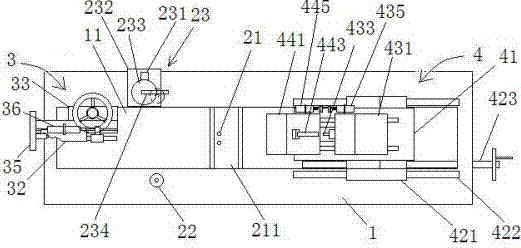

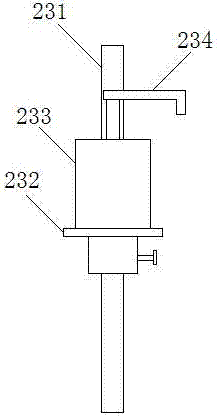

[0025] like figure 1 or figure 2 The wheel hub assembly drilling device shown includes a workbench 1, and a wheel hub fixing device 2 connected to the workbench 1, a valve hole drilling device 3, and a sensor hole drilling device 4; the workbench 1 is provided with a middle Hollow out 11; the valve hole drilling device 3 and the sensor hole drilling device 4 are oppositely arranged on both sides of the hub fixing device 2; the hub fixing device 2 includes a valve groove positioning device 21, a limit post 22, an axial fixing device 23 and radial fixing device 24, the limiting column 22 is symmetrically arranged on the workbench 1 on both sides of the middle hollow 11, the axial fixing device 23 is located on the side of one of the limiting columns 22, and the valve hole drilling device The drill bit of 3, the drill bit of the sensor hole drilling device 4, the valve slot positioning device 21 and the radial fixing device 24 are respectively arranged on the vertical plane whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com