Cuttings collection trolley

A technology for collecting cars and chips, which is applied in the field of mechanical processing, can solve the problems of huge labor load of chips, pollute the ground environment, corrode the cement floor, etc., and achieve the effect of reducing labor intensity, reducing pollution and effectively separating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

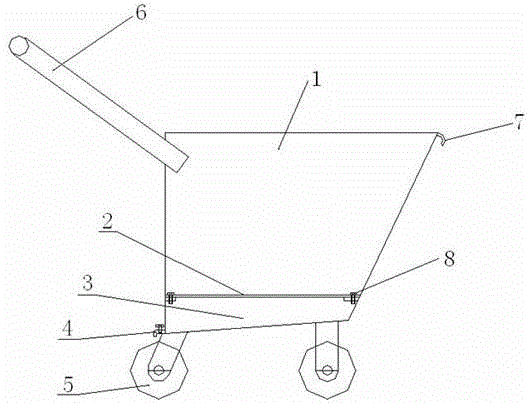

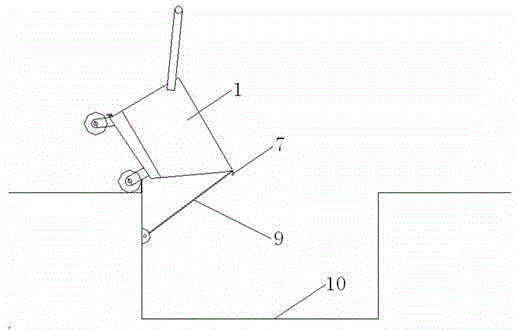

[0015] see figure 1 and figure 2 , the embodiment of the present invention includes:

[0016] A chip collection vehicle, comprising: a trolley main body 1, a filter iron plate 2, a chip liquid collection box 3 and a control valve 4, and also includes a base roller 5 arranged under the trolley main body 1 and fixed behind the trolley main body 1 The dolly push handle 6 on the side upper part.

[0017] The chip fluid collection box 3 is located at the bottom of the trolley body 1, and the bottom of the chip fluid collection box 3 is inclined relative to the trolley body 1, which is helpful for the collection and discharge of the chip fluid. A l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com