Vertical lifting device of materials

A vertical lifting and material technology, which is applied in the field of tobacco leaf devices, can solve the problems of difficulty in ensuring the freshness of tobacco leaves, difficulty in timely picking, and high labor intensity for tobacco farmers, and achieves high efficiency in conveying tobacco leaves, simple structure, and shortened harvesting time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

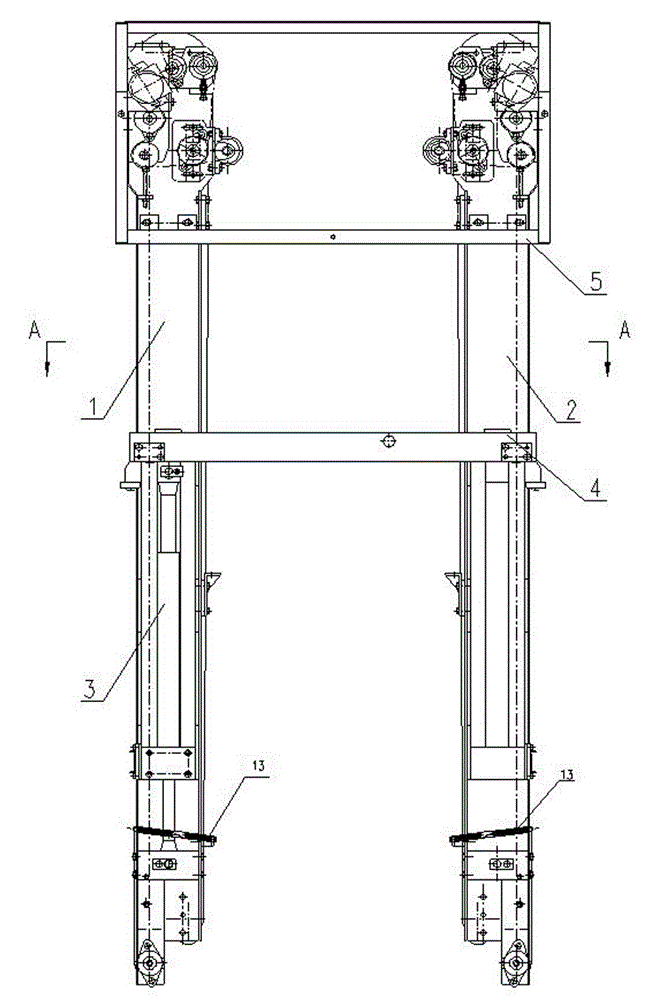

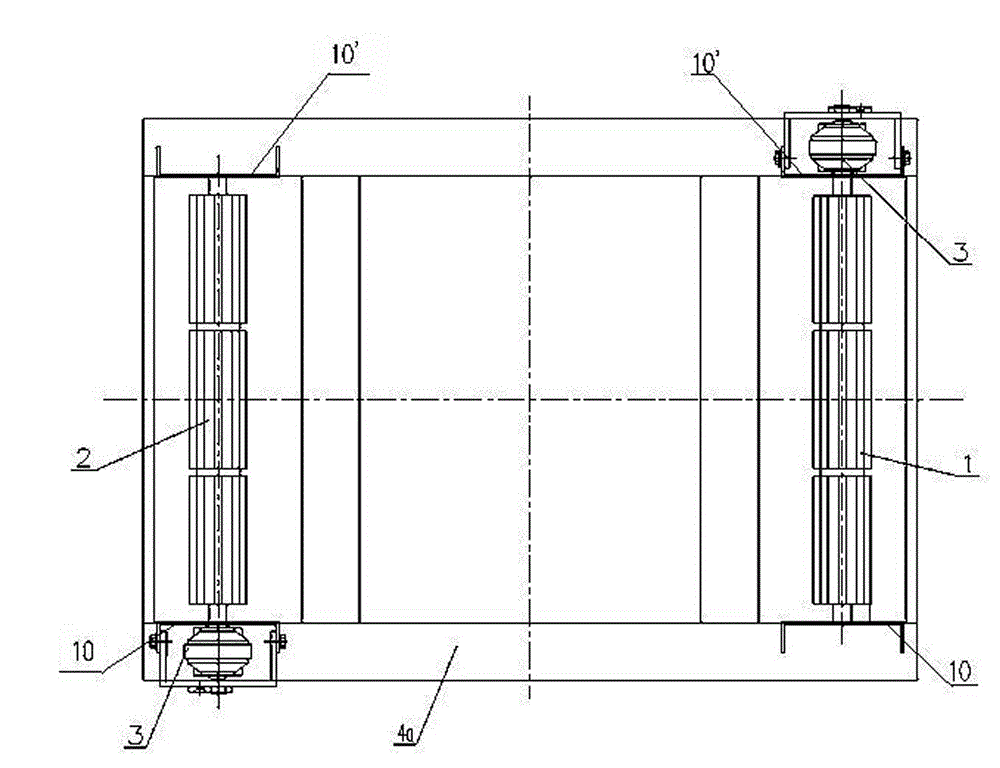

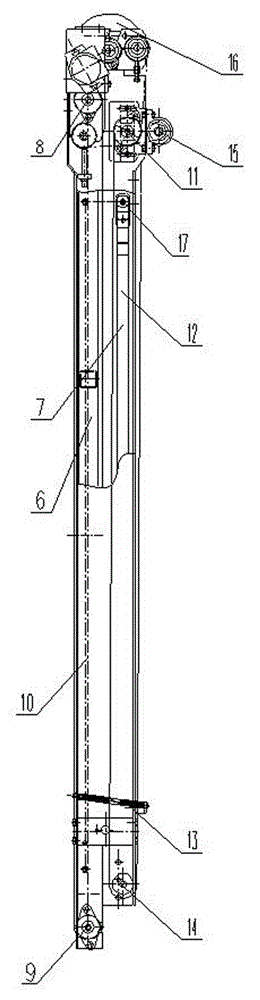

[0016] Such as figure 1 As shown, the present invention includes a symmetrically arranged vertical left conveying mechanism 1 and a right conveying mechanism 2, and a hydraulic lifting mechanism 4 fixedly connected with the left conveying mechanism 1 and the right conveying mechanism 2. On the top of the left conveying mechanism 1 and the right conveying mechanism 2, there are such as Figure 6 The protective device 5 shown has the function of protecting and strengthening the entire vertical lifting device. The protective device 5 is composed of an upper protective device 5a and a lower protective device 5b, the lower protective device 5b is fixed on the front side plate 10 and the rear side plate 10' by screws, and the upper protective device 5a is directly sleeved on the lower protective device 5b, which is convenient for installation and Disassembly, when there is a problem with the transmission device of the left conveying mechanism and the right conveying mechanism, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com