Automatic inclination measurement device for precast pile with rectangular or hollow rectangular cross section

A technology of rectangular cross-section and inclinometer, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of difficult processing and maintenance, unreliable data, high cost, etc., and achieve the light and simple frame design and the degree of synchronization High, low-cost manufacturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

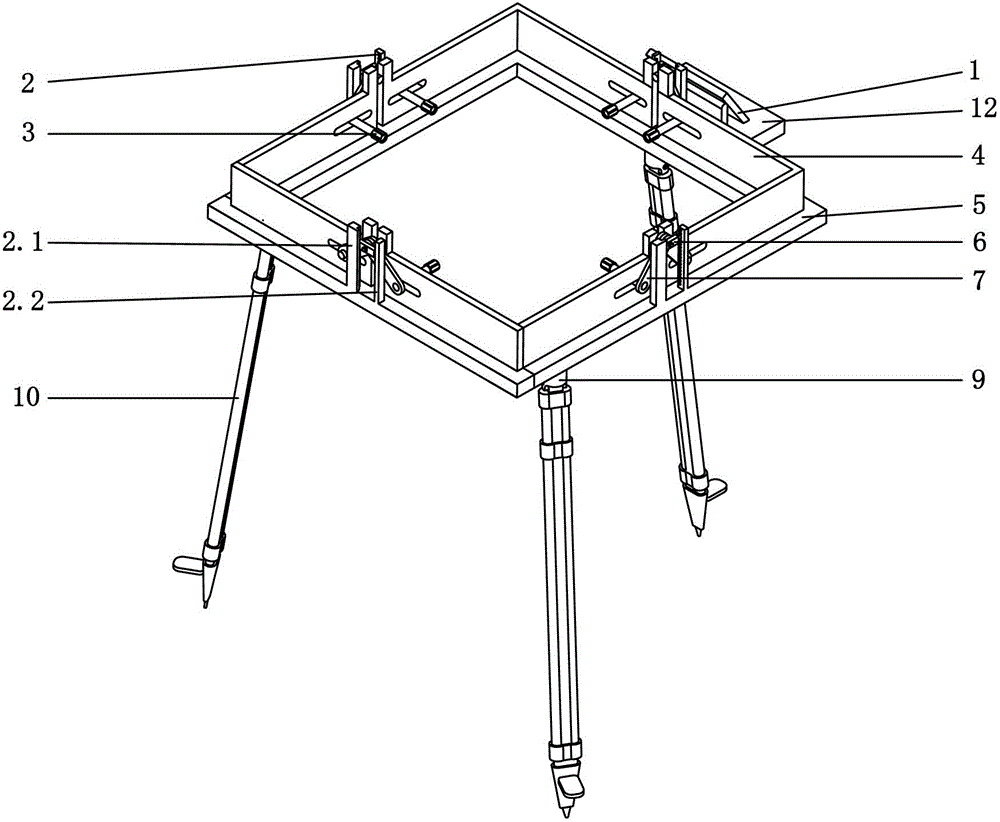

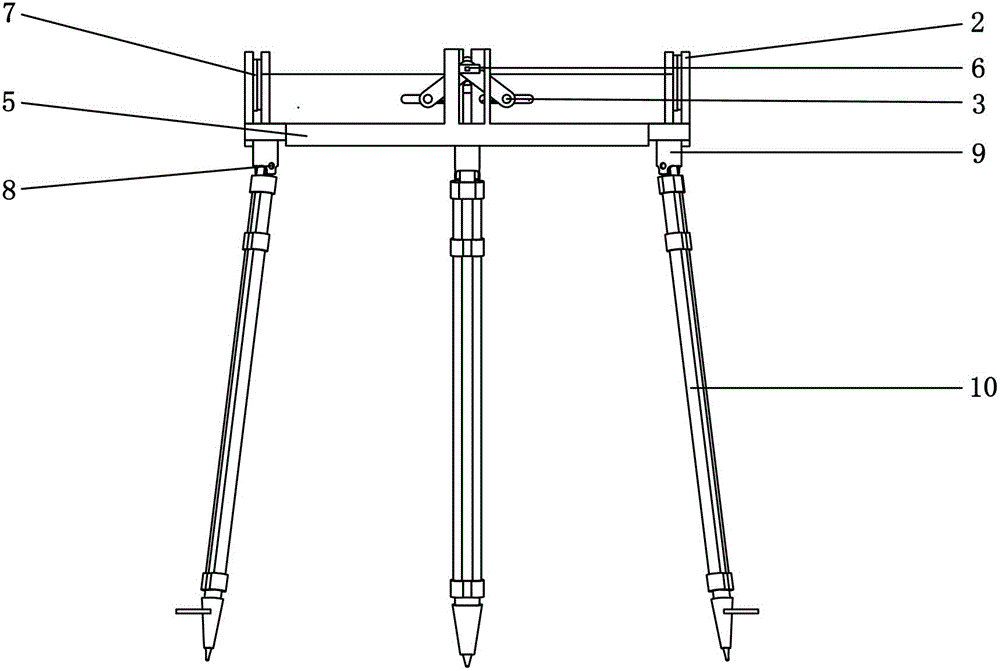

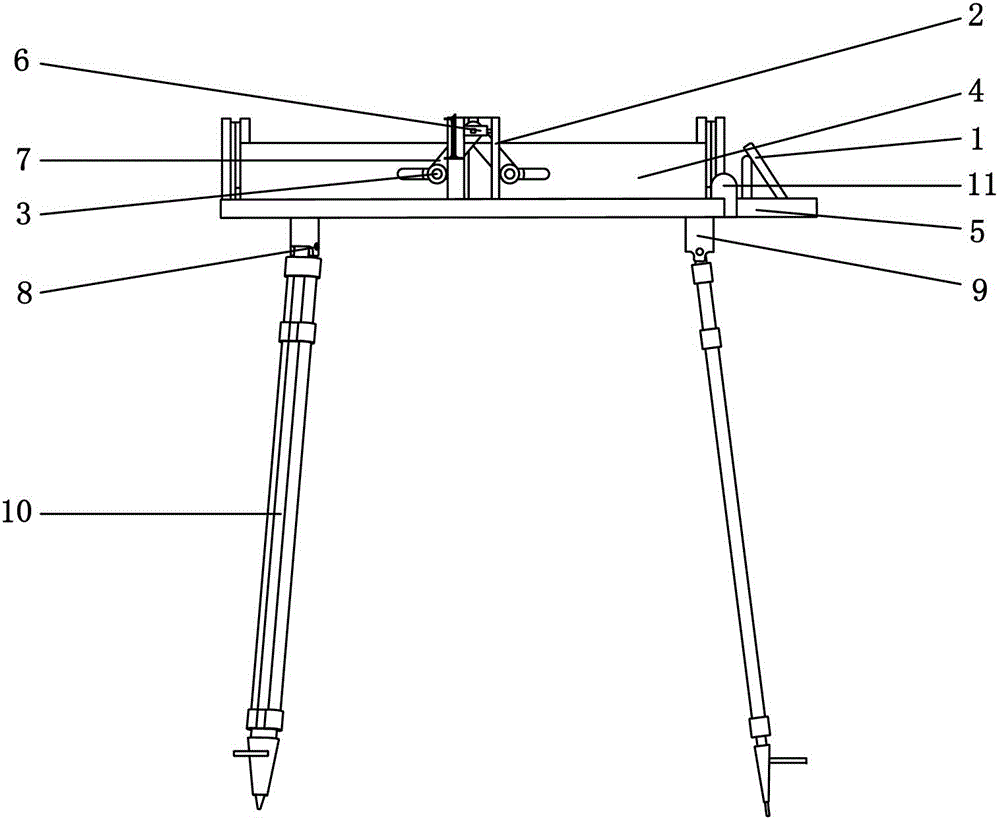

[0044] Such as Figure 1 to Figure 4As shown, an automatic inclinometer measuring device of a rectangular or hollow rectangular section prefabricated pile according to the present invention includes a supporting mechanism, a monitoring and adjusting mechanism and a human-computer interaction platform. Specifically:

[0045] The supporting mechanism includes a bottom plate 5 and a tripod 10 . The cross-section of the bottom plate 5 is in the shape of a rectangular frame. For the convenience of the installation of the whole device, one side of the bottom plate 5 is detachably connected to the other three sides, and in this embodiment, a slot is used for insertion. Connectors 9 are respectively provided on the bottom of the three sides of the integrated base plate 5, and each connector 9 is connected to the legs of the tripod 10 through a pin 8; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com