Temperature rise characteristic field testing method of thermal simulation device of transformer winding temperature controller

A transformer winding and on-site test technology, which is applied to measuring devices, thermometer testing/calibration, instruments, etc., can solve the problem that the temperature controller cannot thermally simulate the temperature rise characteristic test of the device, and achieve the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention easier to understand, the present invention will be further described below in conjunction with the drawings, but the embodiments in the drawings do not constitute any limitation to the present invention.

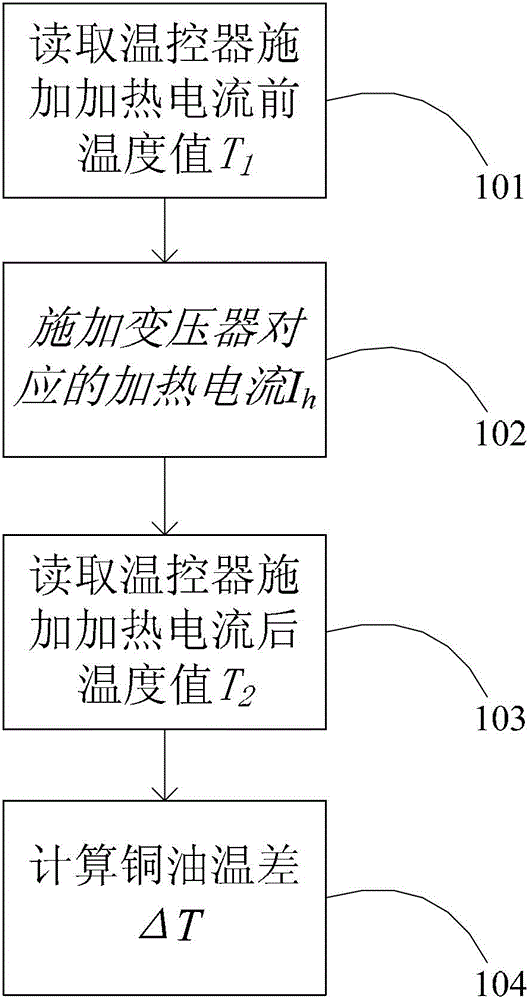

[0015] Such as figure 1 As shown, the embodiment of the present invention is applicable to the flowchart of the test method for temperature rise of the on-site transformer winding type thermometer, and the specific steps of the present invention are as follows:

[0016] a. Keep the thermostat temperature package and the electric heating element installed on the transformer normally. At this time, no test current is applied to the thermostat electric heating element. Controller temperature display value, denoted as T 1 ;

[0017] b. Calculate and determine the test heating current I according to the parameters such as the rated load current of the transformer and the transformation ratio of the current transformer h , and outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com