Even pressure sleeve for measurement of static pressure of pipeline fracture surface

A technology of pipeline section and static pressure, which is used in the measurement of fluid pressure, measuring devices, instruments, etc., can solve the problems of the influence of the accuracy of the static pressure measurement of the pipeline section, the difficulty of air discharge, and the poor uniform pressure effect, so as to improve the uniform pressure effect. , improved reliability and accuracy, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

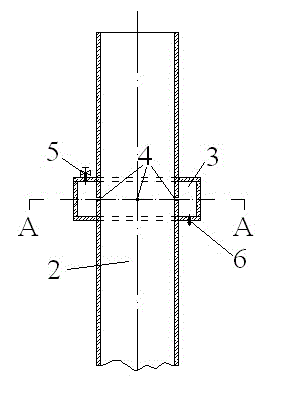

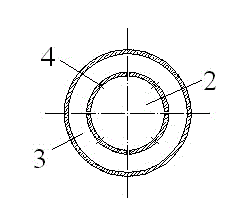

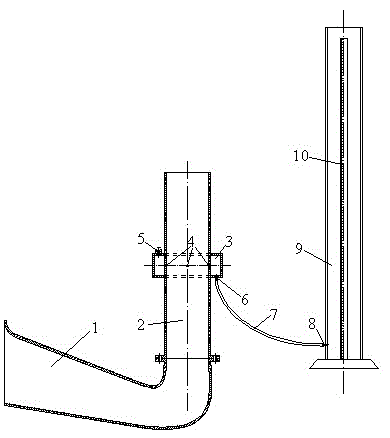

[0012] Such as figure 1 , figure 2 , image 3 As shown, the uniform pressure sleeve used for the static pressure measurement of the pipeline section is composed of an outer plate and an annular top plate and a bottom plate that surround the wall of the tested pipeline. The annular top plate, bottom plate and outer plate are made of transparent materials. . The outer plate is connected with the outer circular edge of the top plate and the bottom plate, and the inner circular edge of the top plate and the bottom plate is closely connected to the wall of the pipe under test. There are 8 pressure-taking holes evenly distributed on the wall of the pipe under test corresponding to the equal pressure sleeve. The 8 pressure-taking holes are in the same section of the pipeline under test. The inner chamber of the uniform pressure sleeve communicates with the measured section of the pipe under test through the pressure-taking hole. The top plate of the uniform pressure sleeve is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com