Grain bin intelligent sensor integration terminal

A smart sensor and sensor technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems that the sensor does not form a unified interface standard and protocol, cannot be connected to equipment in a unified manner and standardized management, and the system lacks coordination. , to achieve the effect of autonomous linkage control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

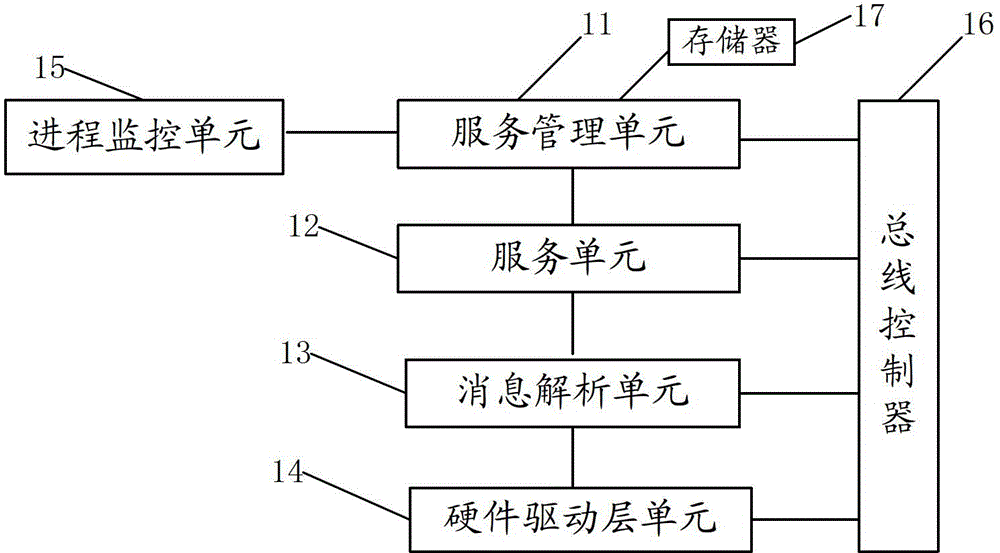

[0023] The specific structure of a grain depot intelligent sensor integrated terminal provided by this embodiment is as follows: figure 1 As shown, the following modules are included:

[0024] The service management unit 11 is used to uniformly configure and manage the parameters, running status and mutual data exchange of each functional module in the service unit through the operating system. Receive the business data reported by the service unit, store and process the business data, and issue control commands for each hardware device to the service unit. This unit configures business rules corresponding to each business through the rule engine, and uses the business rules to perform preliminary processing on the business data to form data with business characteristics.

[0025] The above-mentioned business rules are stored in the memory of the grain depot intelligent sensor integration terminal in the form of a driver file, and the driver file contains a series of user-def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com