Concentric type axial four-division traction transformer and realization method thereof

A traction transformer, four-split technology, applied in transformers, fixed transformers, transformer/inductor cores, etc., can solve the problems that transformers cannot meet, achieve low manufacturing cost, small footprint, limit short-circuit current and eliminate harmonics Significant effect of filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

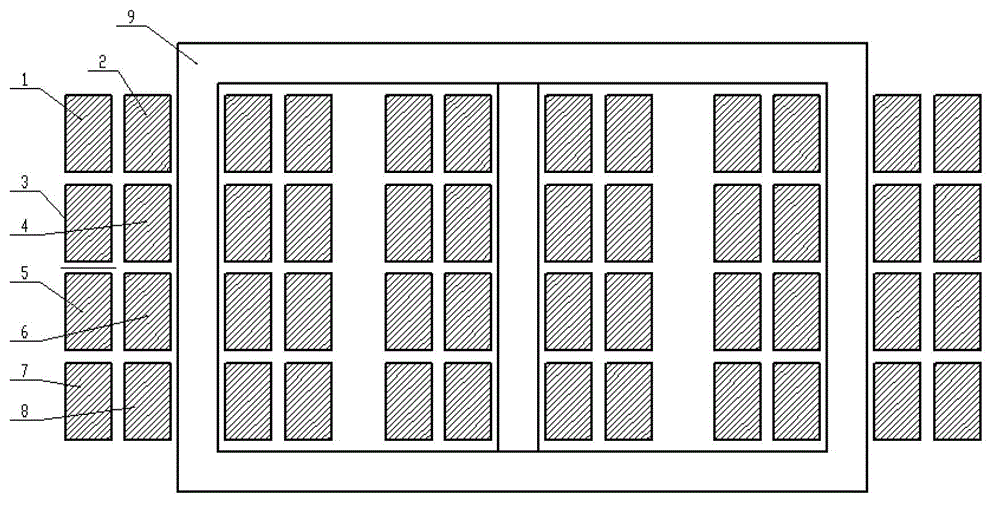

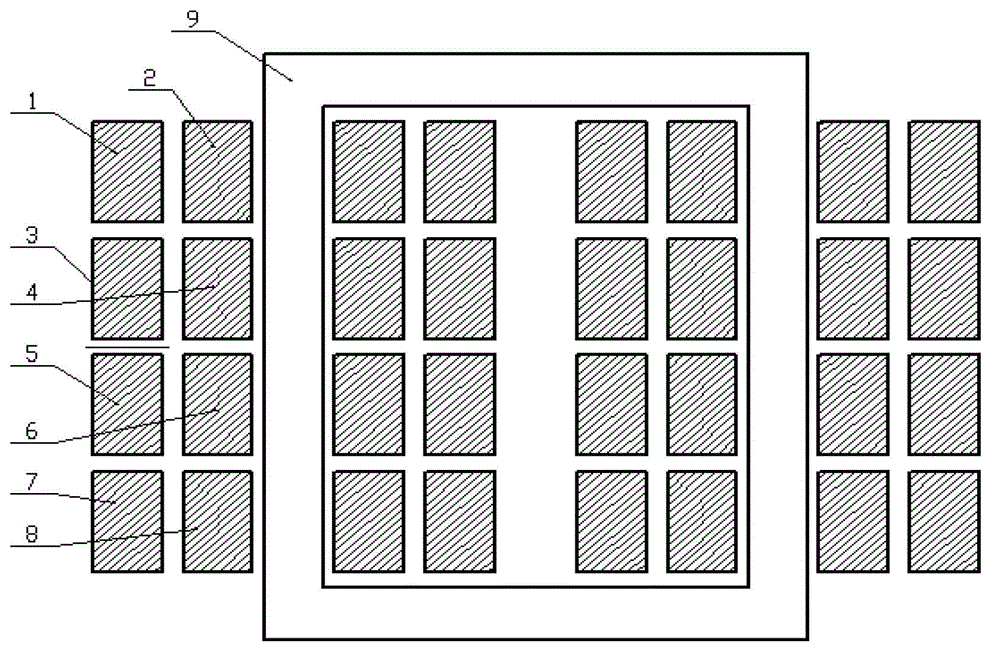

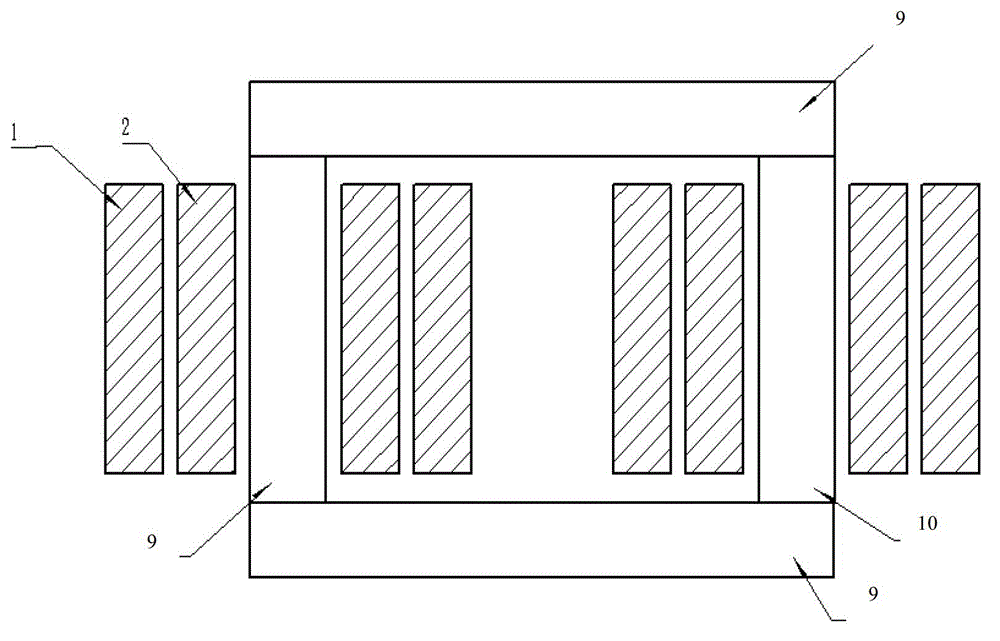

[0032] Such as Figure 1-2 As shown, a concentric axial four-split traction transformer includes an iron core and a winding. The iron core includes at least two single iron core columns; each single iron core column is provided with 4 sets (that is, 4 layers) The windings arranged along the axial direction of the single iron core column, each set of windings is composed of the primary winding on the inner side and the secondary winding on the outer side; and the 4 primary windings are connected in parallel.

[0033] There are 2 single iron core columns. At this time, the concentric axial four-split traction transformer is a single-phase transformer, and the left and right column coils of each layer are connected in series or in parallel to form a separate primary side winding, forming a total of 4 pairs of primary and secondary windings.

[0034] There are 3 single iron core columns. At this time, the concentric axial four-split traction transformer is a three-phase transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com