Single-stage power supply LED (Light Emitting Diode) constant-current driving PWM (Pulse Width Modulation) input dimming circuit

A technology of constant current drive and dimming circuit, applied in the direction of electric light circuit layout, electric light source, light source, etc., can solve the problems of large loss of two-stage circuit, low overall efficiency, temperature rise, etc., to reduce the overall cost and facilitate intelligent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

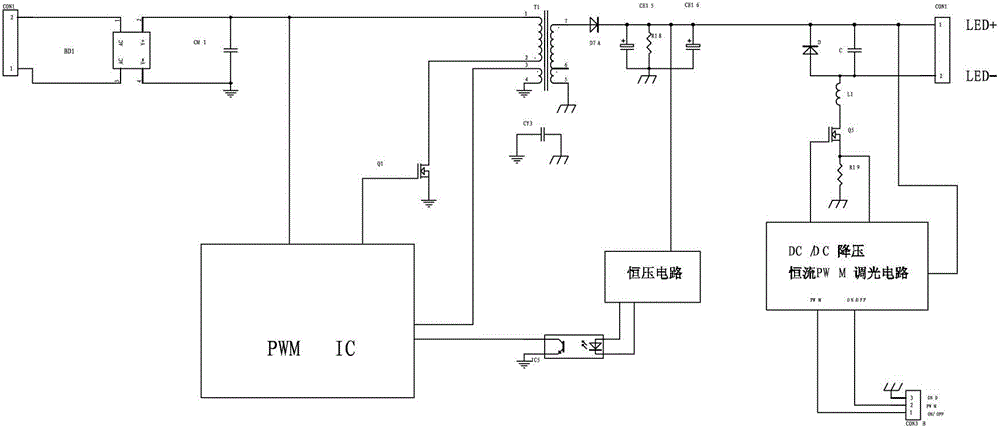

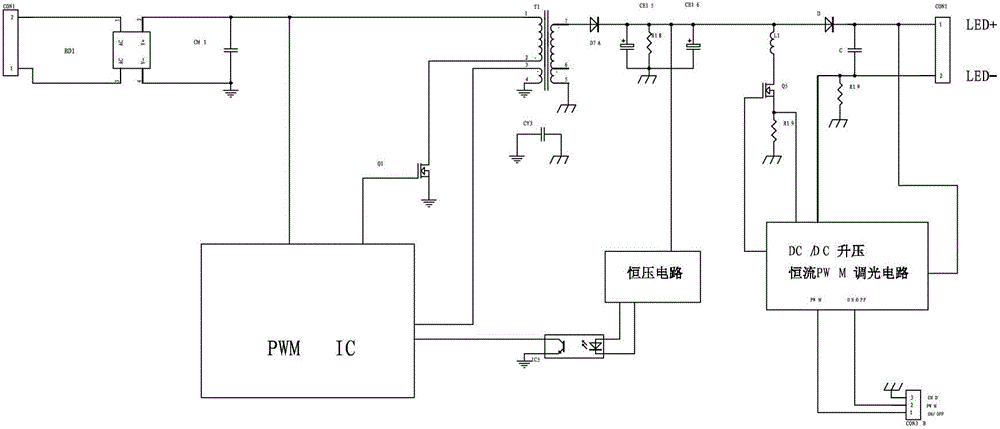

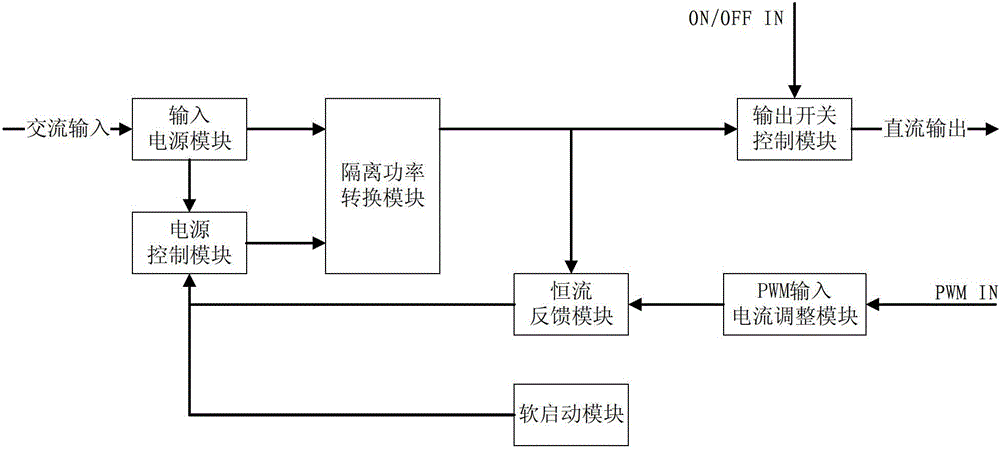

[0038] see image 3 , the present invention provides a single-stage power LED constant current drive PWM input dimming circuit,

[0039] It includes an input power module, a power control module, an isolated power conversion module, a PWM input current adjustment module, a soft start module, an output switch control module and a constant current feedback module.

[0040] The connection relationship of each module is as follows:

[0041] The input power module is provided with an AC input terminal, and the input power module is connected with the power control module and the isolated power conversion module; the isolated power conversion module is provided with a power supply output terminal for supplying power to each module and a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com