Mixing device for prepack vacuum cementing system, vacuum cementing system and method

A mixing device and cement technology, applied in the direction of mixers with rotary stirring devices, chemical instruments and methods, mixers, etc., to achieve the effects of not easy to break down, simple mode of action, and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

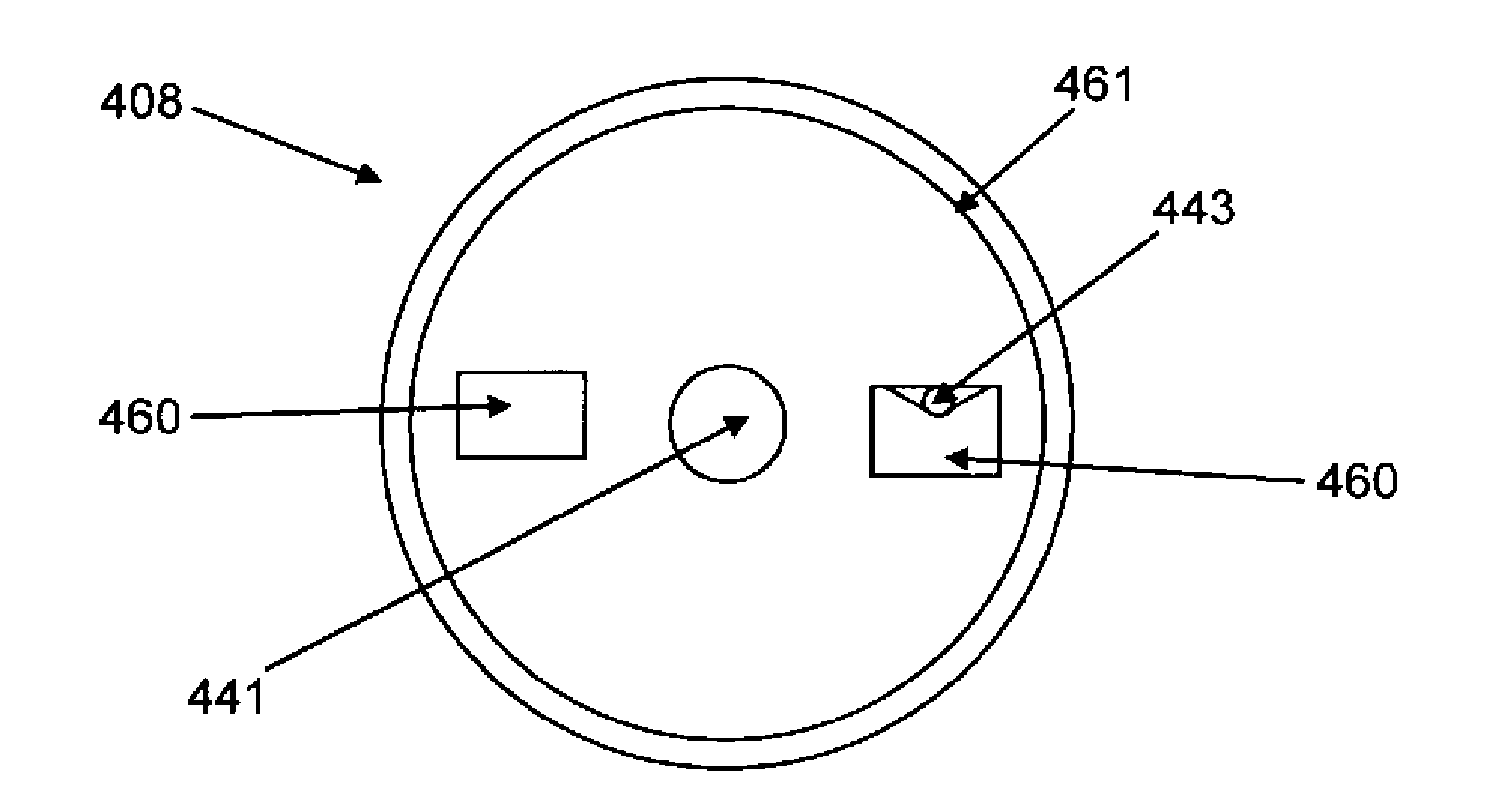

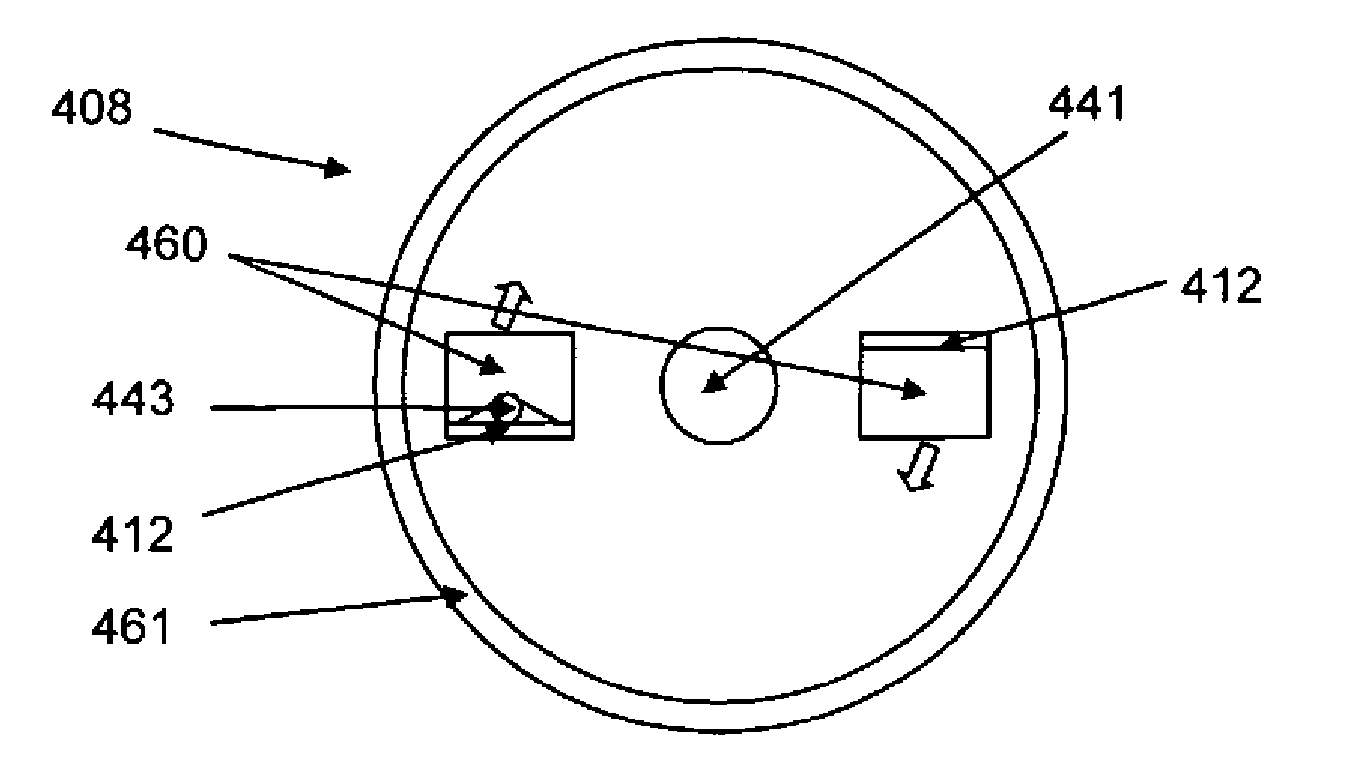

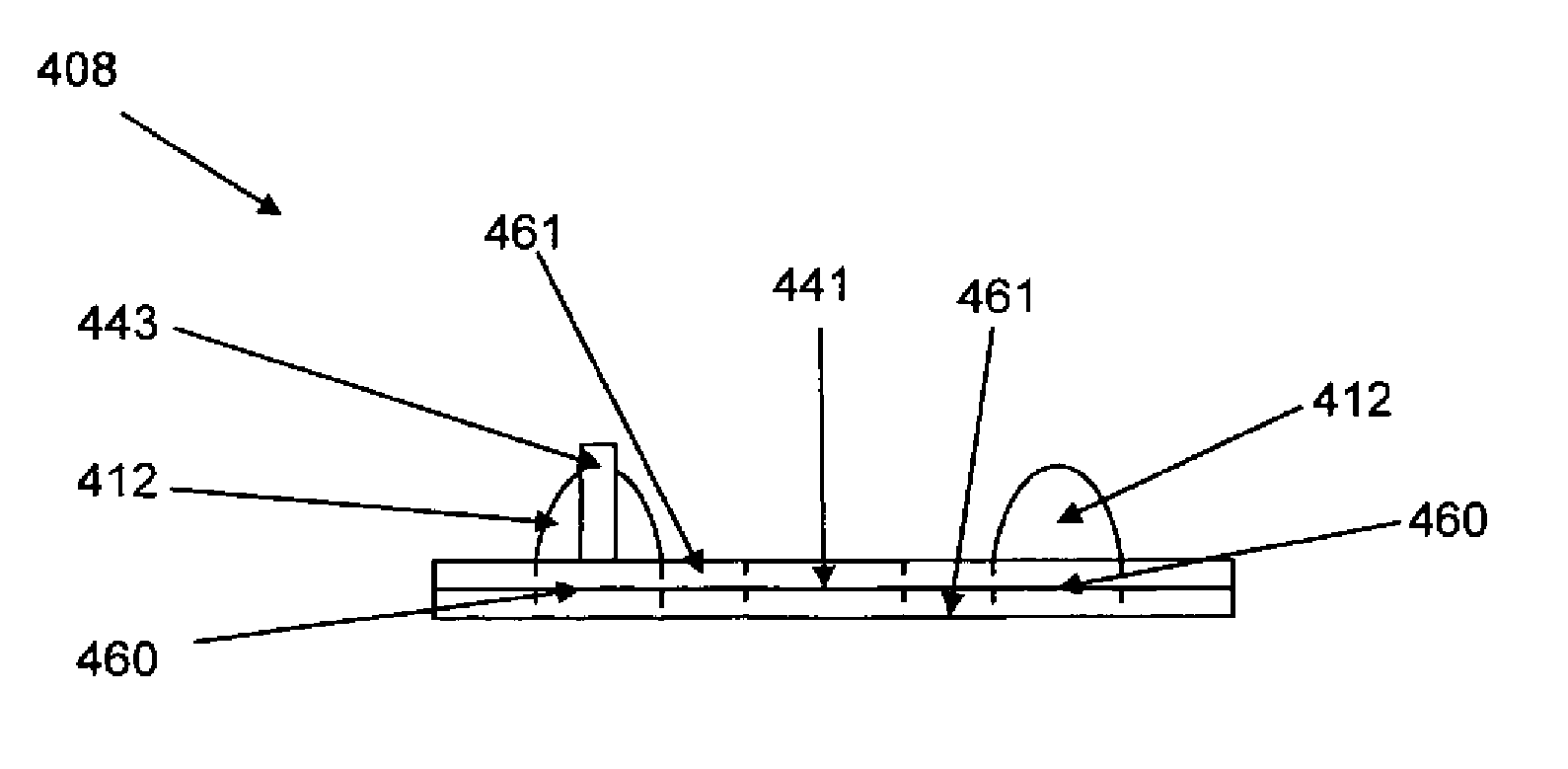

[0060] FIG. 1 shows a schematically illustrated cross-sectional illustration of a mixing device according to the invention. The mixing device ( 1 ) comprises a cartridge ( 2 ) with a cartridge head ( 4 ), which is connected to the cartridge body by fastening means ( 6 ) in the form of threads. The cartridge ( 2 ) is locked on the underside by a delivery piston ( 6 ), which is arranged movably in the direction of the cartridge head ( 4 ). A rotatably supported locking mechanism (8) is arranged under the cartridge head (4), and a fine-pore filter (10) is arranged between the cartridge head (4) and the cartridge (2) under the locking mechanism. between the interior. The fine-pore filter ( 10 ) is used so that the powder stored in the interior of the cartridge ( 2 ) cannot penetrate to the locking mechanism ( 8 ), while the gas can easily pass through the fine-pore filter ( 10 ).

[0061] The locking mechanism ( 8 ) comprises two handles ( 12 ), which extend through two ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com