Electric tool

A technology of electric tools and electric power, which is applied in the direction of motor tools, manufacturing tools, electric controllers, etc., can solve the problems of heavy burden and cumbersome operation of the variable speed switch, and achieve the effect of improving usability, not cumbersome trigger operation, and improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0036] Below, based on Figure 1 to Figure 10 , the electric power tool according to Embodiment 1 of the present invention will be described.

[0037]

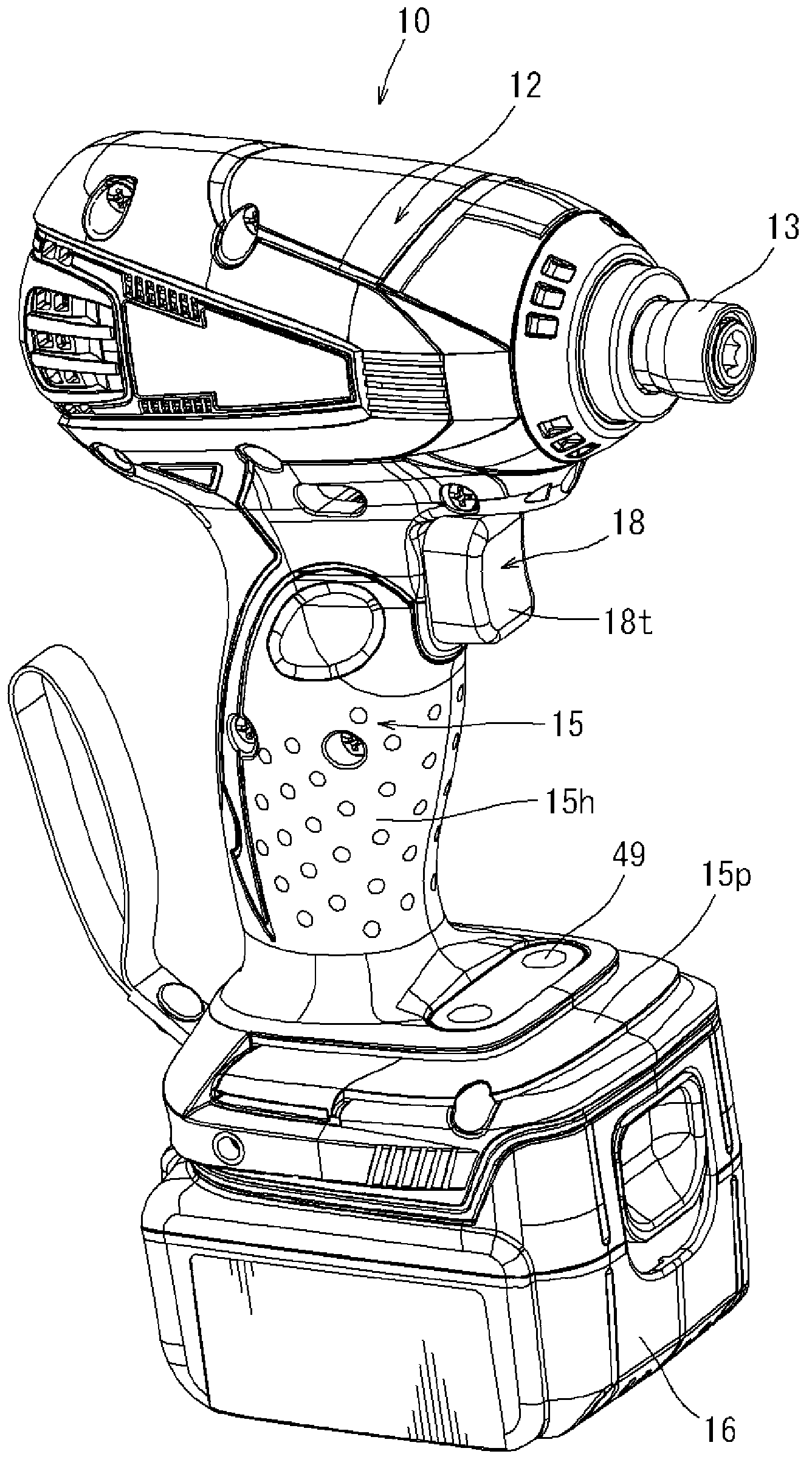

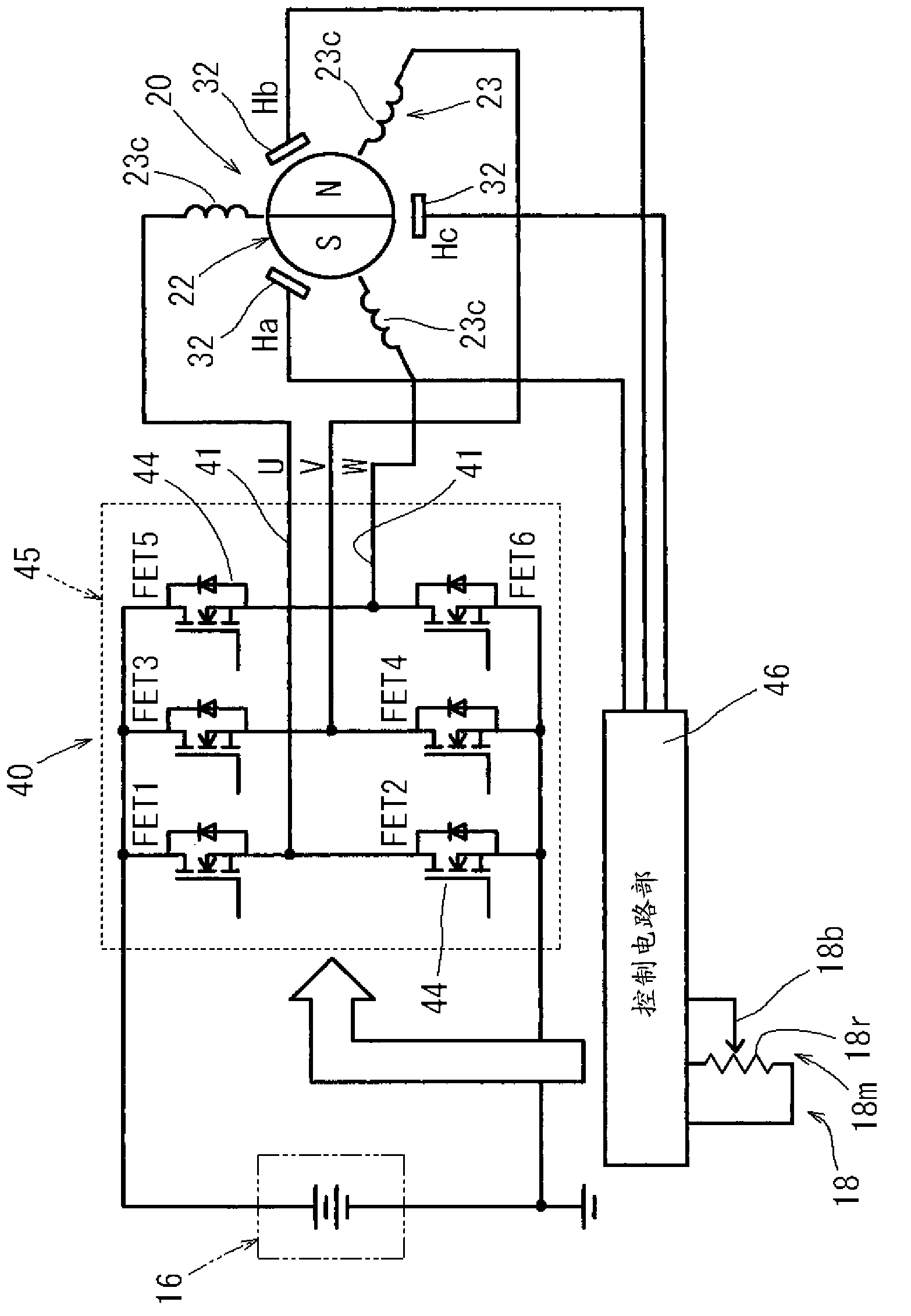

[0038] The electric tool 10 of the present embodiment is an impact drill (rotary impact tool) using a DC brushless motor 20 (hereinafter, referred to as a DC motor 20 ) as a drive source.

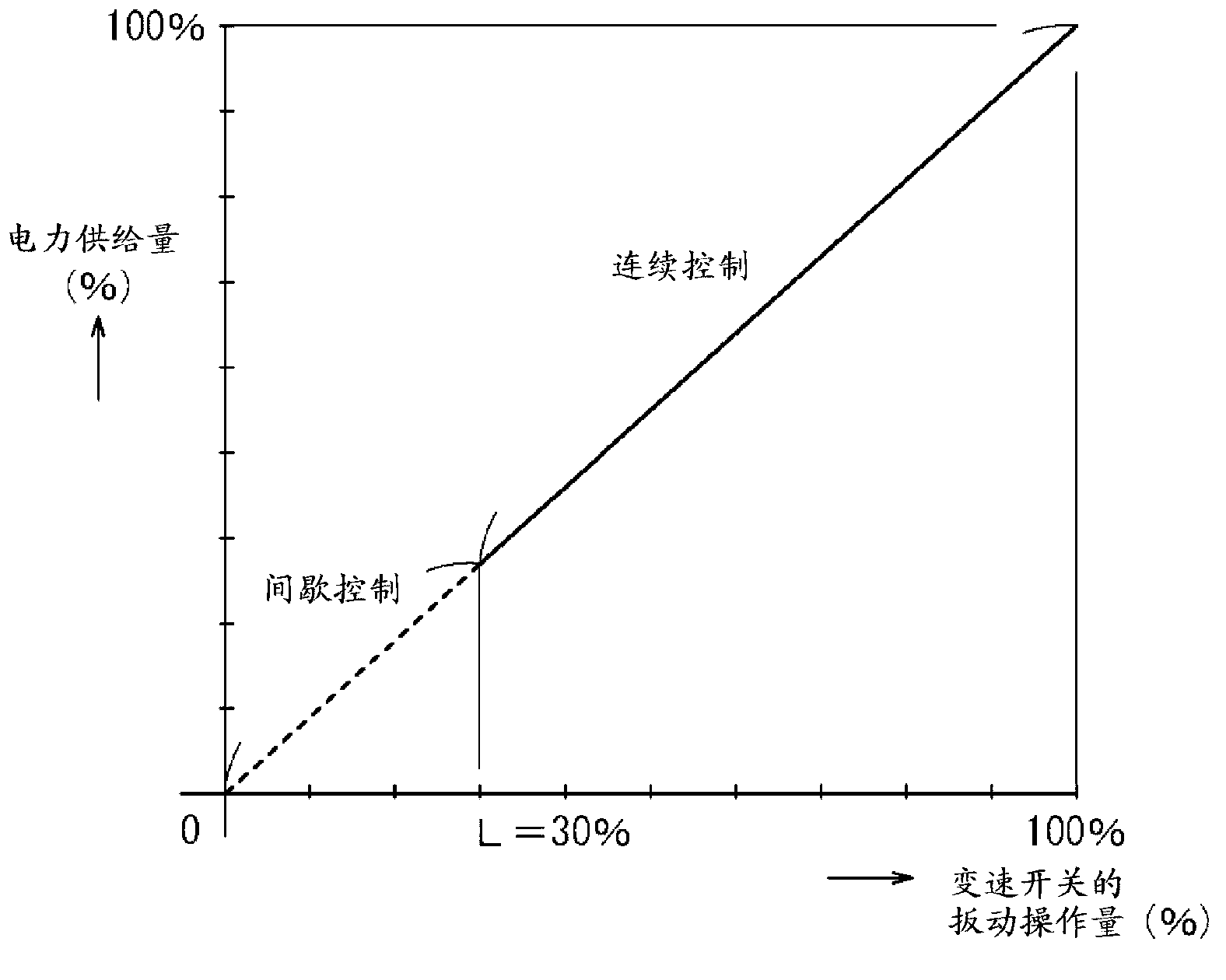

[0039] Such as figure 1 As shown, the electric tool 10 includes a cylindrical housing main body 12 and a handle 15 formed to protrude from a lower portion of the housing main body 12 . The handle portion 15 includes a grip portion 15h that is held by the user when using the electric power tool 10, and a battery connection portion 15p located on the lower side (front end side) of the grip portion 15h. In addition, a speed change switch 18 for a user's fingertip manipulation is provided at the base end portion of the grip portion 15h. Moreover, the connection mechanism (not shown) which connects the battery case 16 is provided in the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com