Bottle delivery device of bottle washing machine

A bottle washing machine and bottle conveying technology, which is applied in the field of bottle washing machines, can solve the problems of increasing investment cost, restricting pharmaceutical production, and unfavorable smooth movement of bottles, so as to improve cleaning effect and efficiency, realize assembly line operation, and be conducive to smooth running. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the present invention will be further described with embodiment:

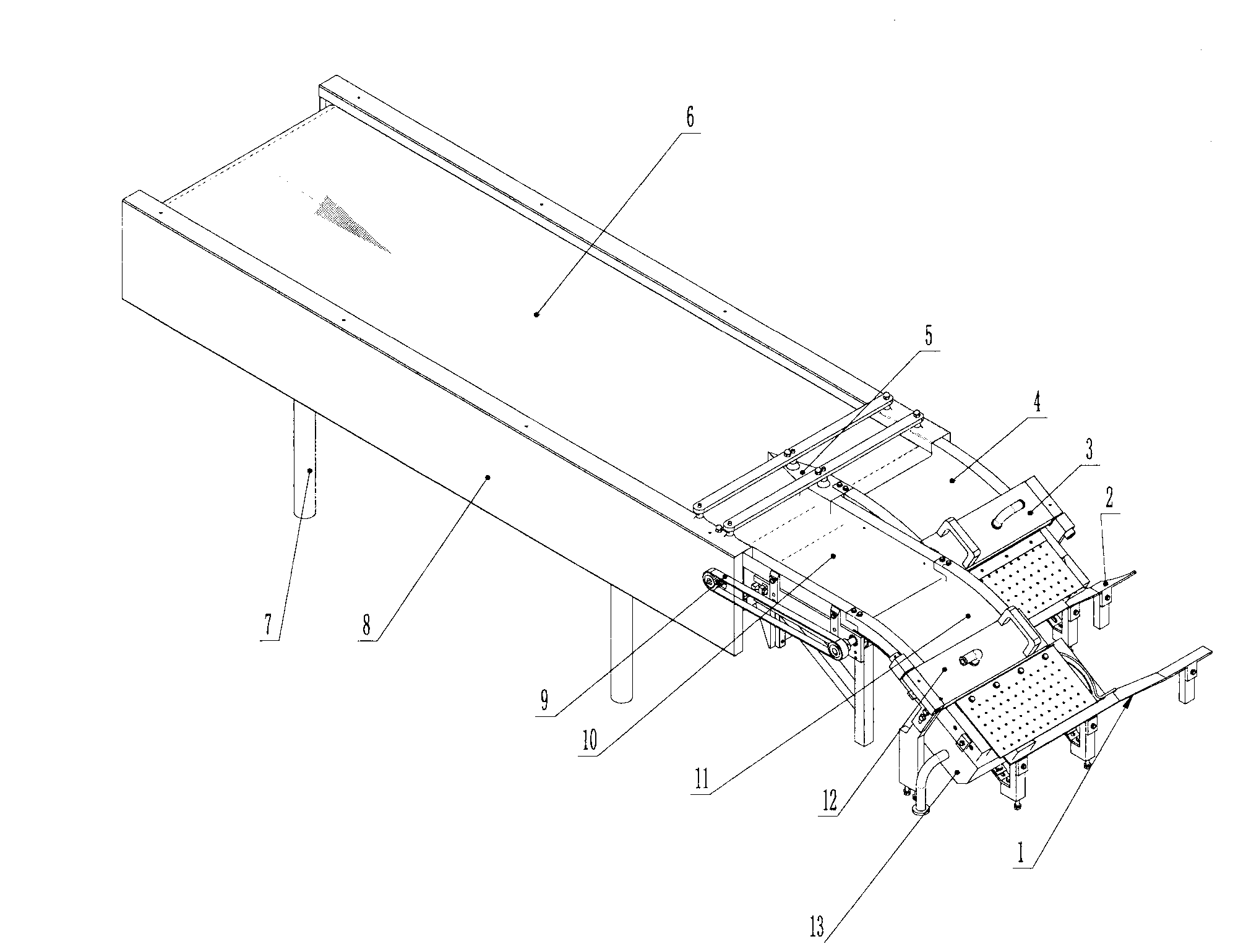

[0008] See attached figure 1 , the complete machine is located on the frame 7, the frame 7 both sides are fixed with cover plates 8, the right end of the frame 7 is provided with a mesh belt conveyor chain 6, the mesh belt conveyor chain 6 upper side is fixed with a bottle dividing mechanism 5, and the bottle The front side of the mechanism 5 is provided with a transition channel 10, and the other side is provided with a channel 4 for entering bottles B, and the synchronous belt 9 is respectively connected to the driving wheel of the mesh belt conveyor chain 6 and the transition channel 10. The front end of the transition channel 10 is connected with the bottle inlet A channel 11, and the end of the bottle inlet A channel 11 is provided with a spray A groove 12, which is connected with the ultrasonic mechanism 13, and the front end of the ultrasonic mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com