Vehicle luggage rack and installation method

An installation method and luggage rack technology, which are applied in transportation and packaging, railway car body parts, etc., can solve the problems of luggage rack frame structure damage, mechanical parts damage, scratched glass, etc., to reduce maintenance costs, less operating time, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

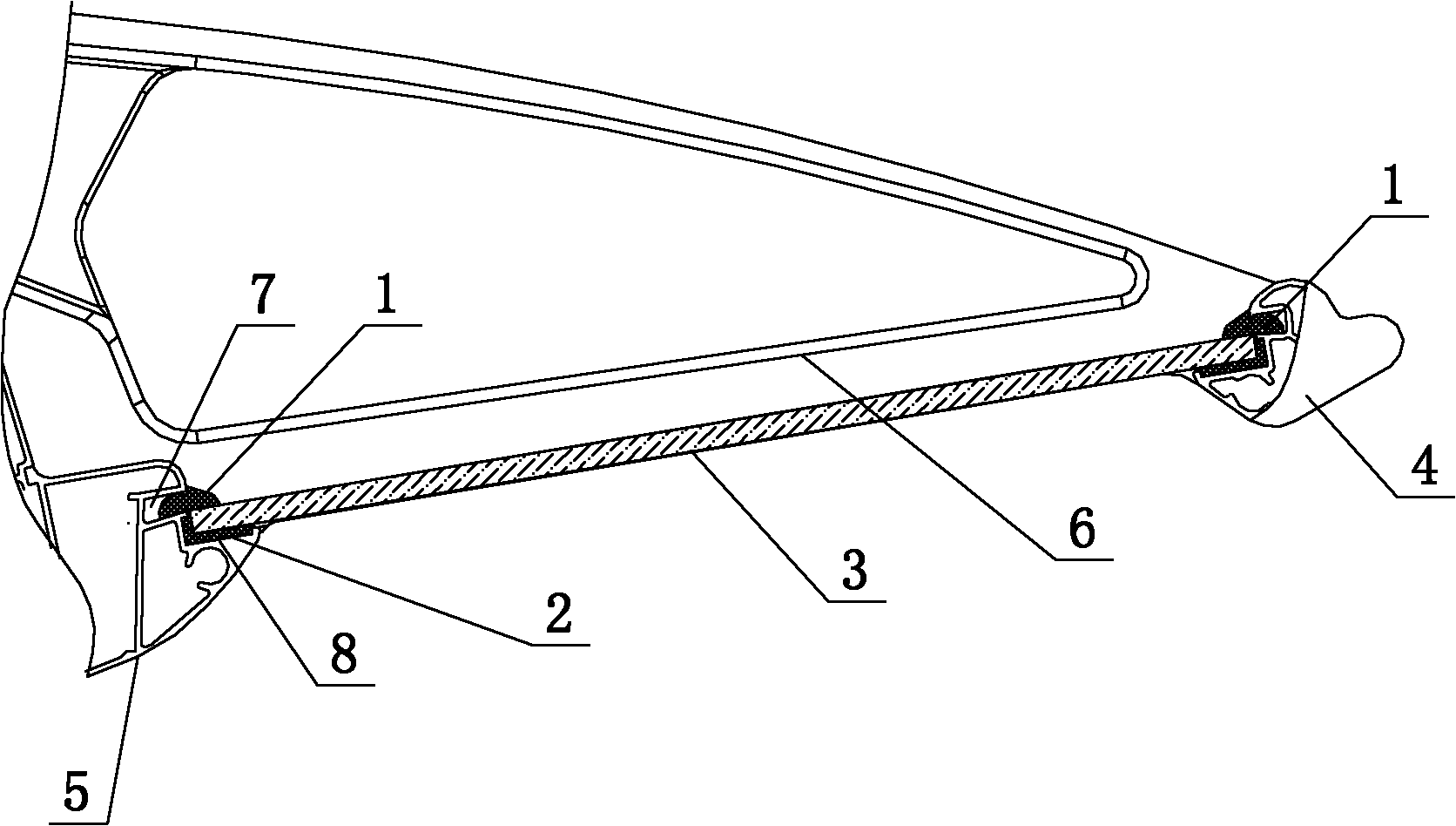

[0036] Example 1, such as figure 1 and figure 2 As shown, the vehicle luggage rack mainly includes:

[0037] A frame structure composed of front profile 4, rear profile 5 and end plates 6 on both sides. The rear profile 5 is installed on the side wall (not shown) inside the passenger room, between the front profile 4 and the rear profile A glass loading plate 3 is embedded.

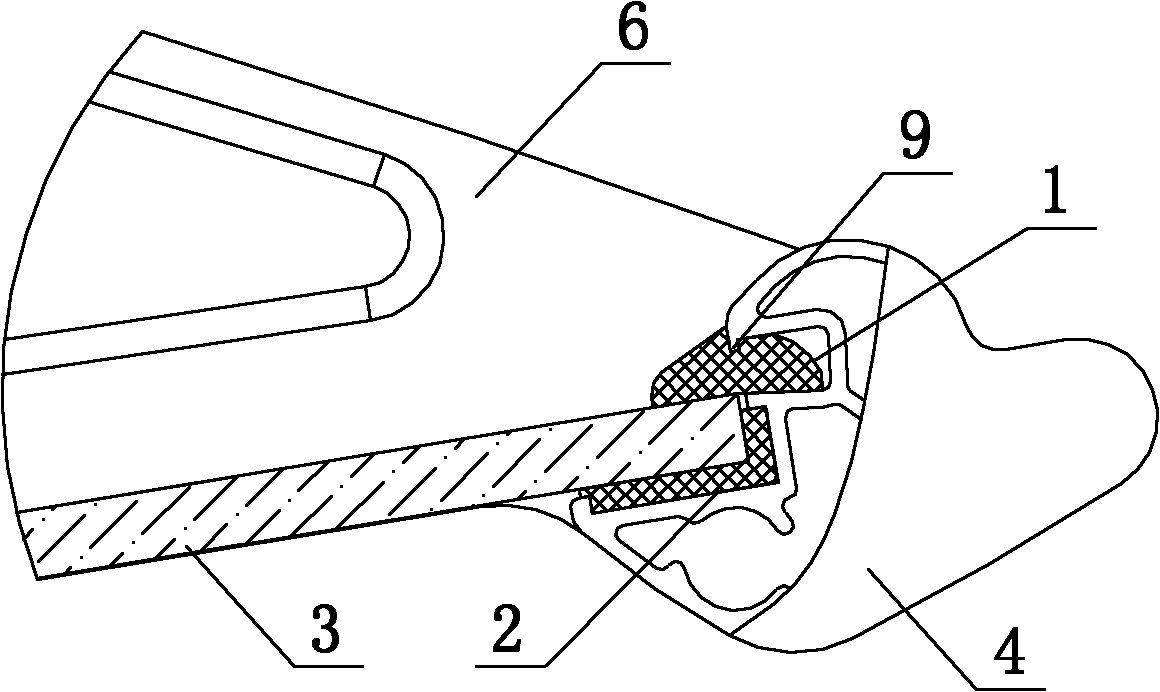

[0038] Wherein, in the cross-sectional structure of the front profile 4 and the rear profile 5, vertically arranged installation grooves 7 and positioning grooves 8 are symmetrically arranged;

[0039] The front and rear ends of the glass load plate 3 are respectively placed in the installation grooves 7 of the front profile 4 and the rear profile 5;

[0040] Between the front and rear ends of the glass load plate 3 and the installation groove 7 there is an anti-vibration rubber strip 2 bonded to the installation groove 7 through the back glue;

[0041] Two sets of rubber bead 1 are respectively embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com