Design method of 7-meter front-arranged passenger car chassis frame

A bus chassis and design method technology, applied to vehicle parts, substructure, transportation and packaging, etc., can solve the problems that passengers cannot get on and off the bus quickly, and achieve improved stability and comfort, large interior space, and increased riding The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

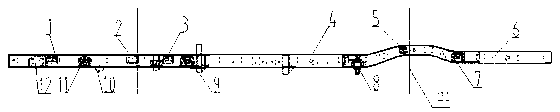

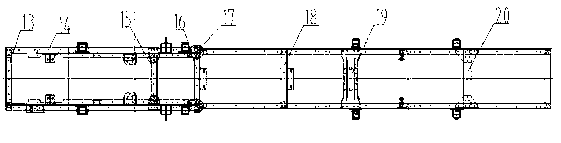

[0013] A chassis frame of a 7-meter front passenger car, comprising: brackets, beams and longitudinal beams, the longitudinal beams are composed of two front longitudinal beams 14 on the left and right, two middle longitudinal beams 4 on the left and right, and two rear longitudinal beams 6 on the left and right Composition, described crossbeam is made up of first crossbeam 13, second crossbeam 15, third crossbeam 16, fourth crossbeam 18, fifth crossbeam 19, sixth crossbeam 20; The connecting plate 17 at the end is butted with one end of the two middle longitudinal beams 4, the other end of the two middle longitudinal beams 4 is butted with the two rear longitudinal beams 6, and the first beam 3 and the second beam 15 are welded between the two front longitudinal beams 14 , the fourth beam 18 and the fifth beam 19 are welded between the two middle longitudinal beams 4, and the sixth beam 20 is welded between the two rear longitudinal beams 6; the cross section of the front long...

Embodiment 2

[0015] Such as figure 1 and 2 As shown, a 7-meter front passenger car chassis frame includes: a support, a crossbeam and a longitudinal beam, and the described longitudinal beam is composed of two front section longitudinal beams 14, two middle section longitudinal beams 4 on the left and right sides, and two rear section longitudinal beams on the left and right sides. Longitudinal beam 6 is made up of, and described crossbeam is made up of first crossbeam 13, second crossbeam 15, third crossbeam 16, fourth crossbeam 18, fifth crossbeam 19, sixth crossbeam 20; The connecting plates 17 at both ends of the beam 16 are connected to one end of the two middle longitudinal beams 4, the other ends of the two middle longitudinal beams 4 are connected to the two rear longitudinal beams 6, and the first beam 3 and the second longitudinal beam 14 are welded between the two front longitudinal beams 14. Two crossbeams 15, the fourth crossbeam 18 and the fifth crossbeam 19 are welded betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com