Method for prediction of blast furnace heat tendency

A blast furnace and blast furnace molten iron technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as inability to obtain the trend of heat development inside the blast furnace, and unsatisfactory prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with specific embodiment the method for forecasting blast furnace heat tendency of the present invention is further described:

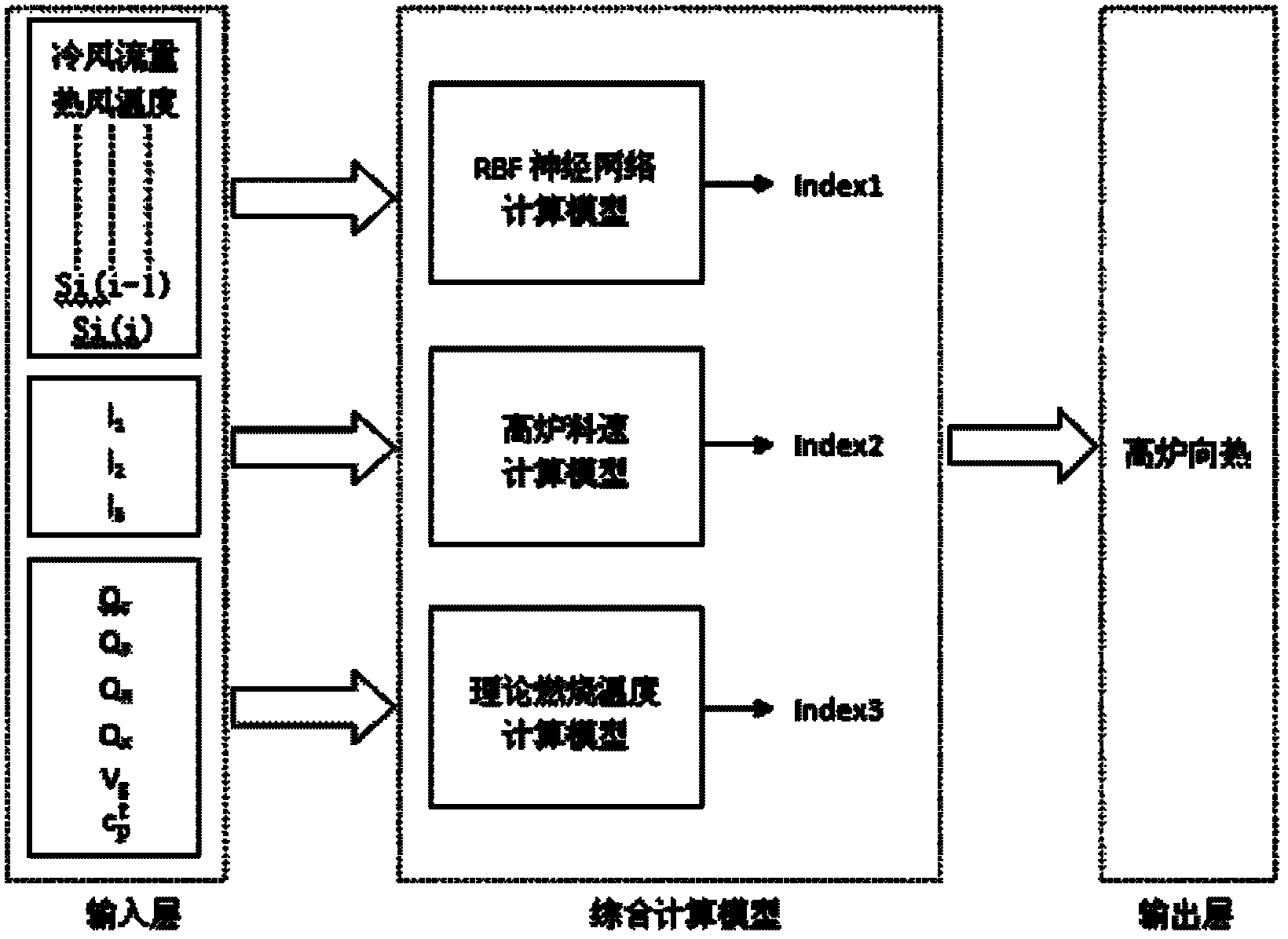

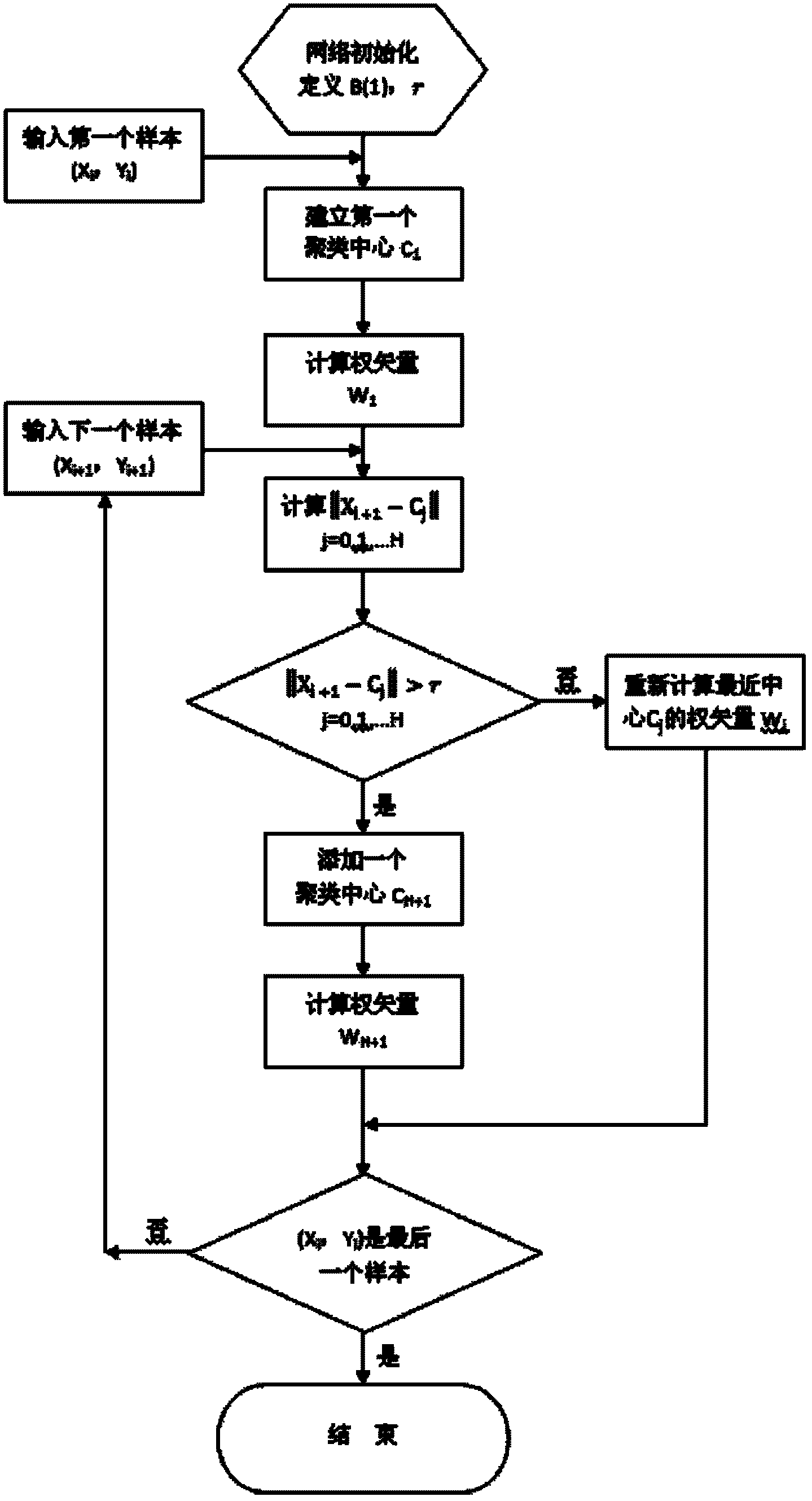

[0065] The present invention designs three calculation schemes altogether, respectively is the Si content in molten iron of blast furnace and blast furnace heat development trend scheme, blast furnace material speed calculation model calculation result and blast furnace heat tendency judgment scheme, theoretical combustion temperature calculation model calculation result and blast furnace direction Thermal trend judgment scheme. According to the calculation principle of the scheme, such as figure 1 As shown, a total of three calculation models are required, namely, the RBF neural network calculation model, the blast furnace material velocity calculation model, and the theoretical combustion temperature calculation model. The RBF neural network calculation model can calculate the level of silicon content in the blast furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com