Prestressed concrete pipe pile butt joint construction member and prestressed concrete pipe pile

A technology for concrete pipe piles and butt joint components, which is applied in sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as rotten end plates at welding parts, poor butt joint quality between upper section piles and lower section piles, and inability to realize riveted connections, etc. problem, to achieve reliable transmission and ensure reliable docking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

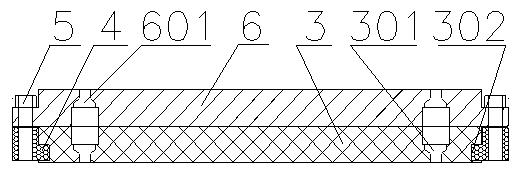

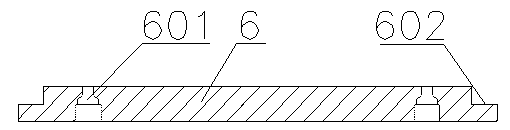

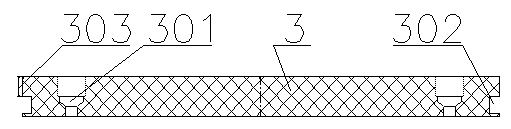

[0016] Example 1: Refer to the attached Figure 1-6 . A prestressed concrete pipe pile butt joint component includes a prestressed concrete pipe pile butt joint end plate. The prestressed concrete pipe pile butt joint end plate is composed of a boss-shaped flange end plate 6, a ring groove-shaped clamping end plate 3, and two A half-annular boss lock ring 4 and bolts 5 are formed; the end face of the boss-shaped flange end plate 6 coincides with the end face of the ring groove-shaped clamping end plate 3, and the boss 401 is inserted into the ring of the two half-annular boss lock ring 4 The groove-shaped clamping end plate 3 and the surrounding of the boss-shaped flange end plate 6 are connected with the bolt threaded holes 403 on the convex pillars of the two semi-annular boss lock rings 4 through a plurality of bolts 5. The thickness 303 of the upper wall of the ring groove in the ring groove-shaped clamping end plate 3 is greater than the height of the boss post 402 of the...

Embodiment 2

[0017] Example 2: Refer to the attached Figure 7 . On the basis of embodiment 1, a prestressed concrete pipe pile composed of claims 1-7, the boss-shaped flange end plate 6 and the ring groove-shaped clamping end plate 3 are respectively located on the two prestressed concrete pipe piles 1. The end, and the boss-shaped flange end plate 6 and the ring groove-shaped clamping end plate 3 are connected by a steel rod 2. The two ends of the steel rod 2 have a head-shaped structure and are respectively clamped in the head clamping hole 301 of the boss-shaped flange end plate 6 and the ring groove-shaped clamping end plate 3 head clamping hole (601) Inside.

Embodiment 3

[0018] Example 3: Refer to the attached Figure 7 . On the basis of Examples 1 and 2, a butt joint structure between prestressed concrete pipe piles constituted by claim 8. The boss-shaped flange end plate 6 of the upper section of the prestressed concrete pipe pile 1 and the lower section Stressed concrete pipe pile 1 ring groove-shaped clamping end plate 3 faces coincide, two semi-annular boss lock ring 4 middle boss 401 is inserted into the ring groove of ring groove-shaped clamping end plate 3 and boss-shaped flange end plate 6 is connected with bolt threaded holes 403 on the convex pillars of the two semi-annular boss lock rings 4 by a plurality of bolts 5 around the circumference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com