A centrifugal hydrogen sulfide compressor

A compressor and hydrogen sulfide technology, applied in mechanical equipment, non-variable pumps, non-volume pumps, etc., can solve the problems of hydrogen sulfide gas pressurization, achieve high compression ratio, improve efficiency, and eliminate gas leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

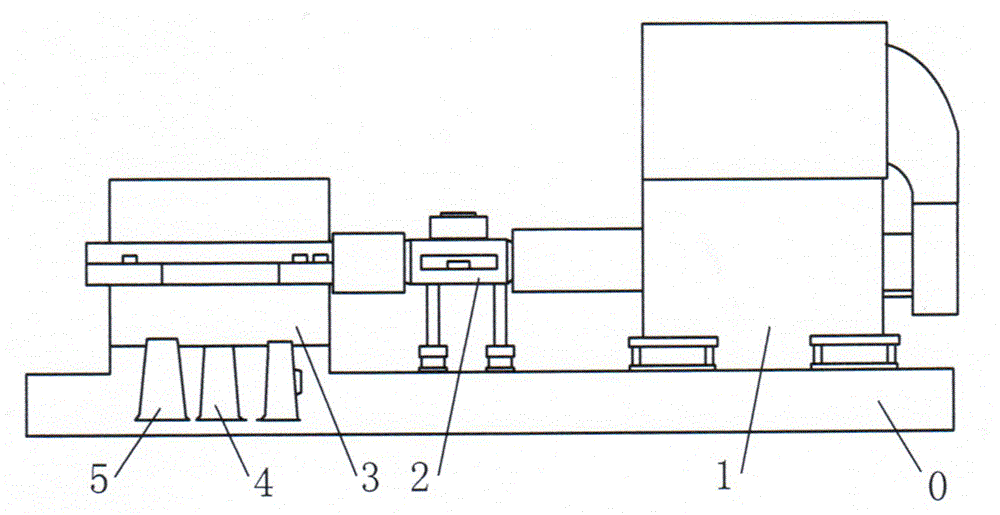

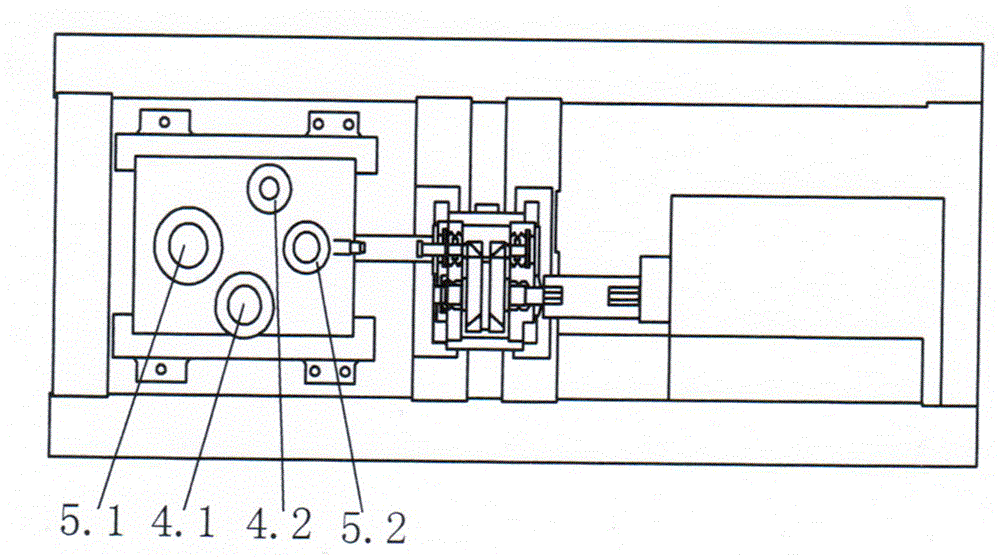

[0029] according to figure 1 and figure 2 As shown, the driving motor 1 installed on the base 0 is connected to the main compressor 3 through the speed increaser 2. The main compressor is provided with an exhaust chamber 4 and an air intake chamber 5. The exhaust chamber is divided into a section of exhaust chamber 4.1 and the second-stage exhaust chamber 4.2, the air intake chamber is divided into a first-stage air intake chamber 5.1 and a second-stage air intake chamber 5.2;

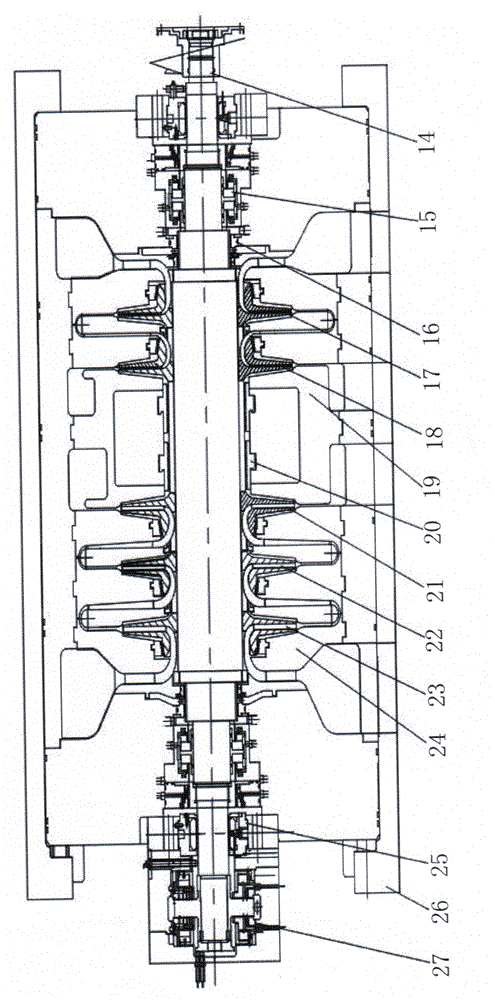

[0030] according to image 3 As shown, the compressor main shaft 14 is installed between two radial bearings 25, a thrust bearing 27 is installed on the outer side of one radial bearing, and the compressor main shaft in the cylinder body 26 is installed in sequence from right to left There are dry gas seals 15, shaft end seals 16, four-stage impellers 17 and five-stage impellers 18, which constitute the second stage, and an outlet volute 19 is provided on one side of the fifth-stage impeller, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com