Detection tool for detecting coaxiality and lengths of sliding sleeve spline and sliding sleeve shaft neck

A coaxiality and spline technology is applied in the field of inspection tools for detecting the coaxiality and length of the sliding sleeve spline and the sliding sleeve journal, and can solve the problem that cannot detect the axis line and the sliding sleeve of the sliding sleeve journal. The problems such as splines, cumbersome detection process, unfavorable production efficiency, etc., achieve the effect of simple and fast detection process, simple measurement process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

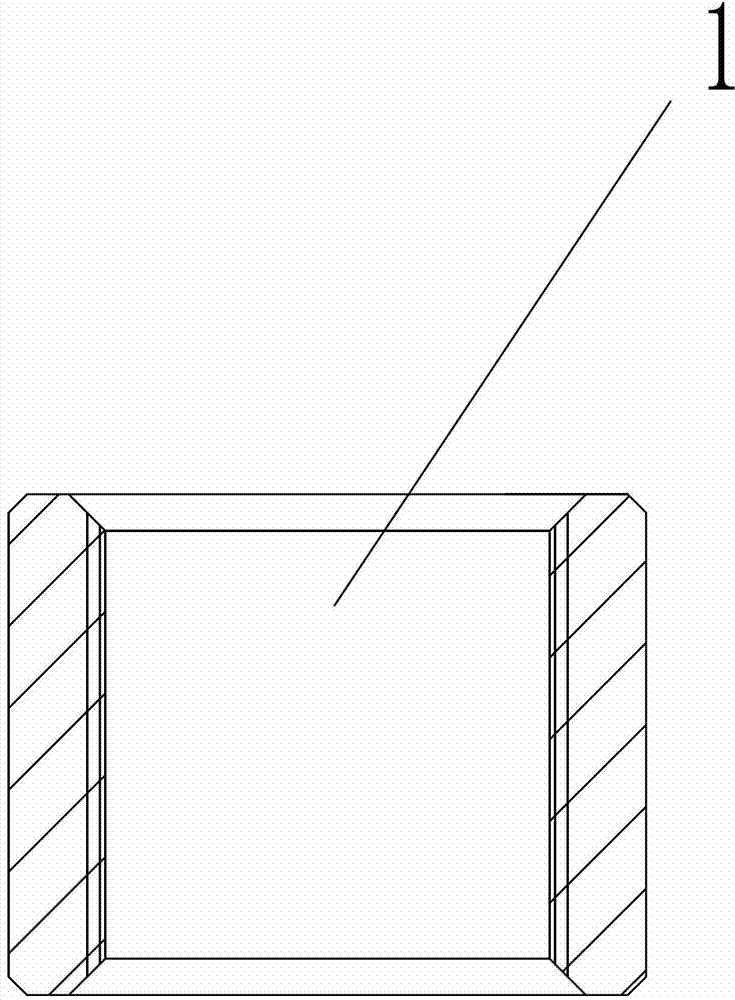

[0033] Embodiment: A checker for detecting the coaxiality and length of the spline of the sliding sleeve and the journal of the sliding sleeve, such as Figure 11 As shown, it includes: spline ring gauge 1, shaft sleeve ring gauge 4 and outer outer ring gauge 7.

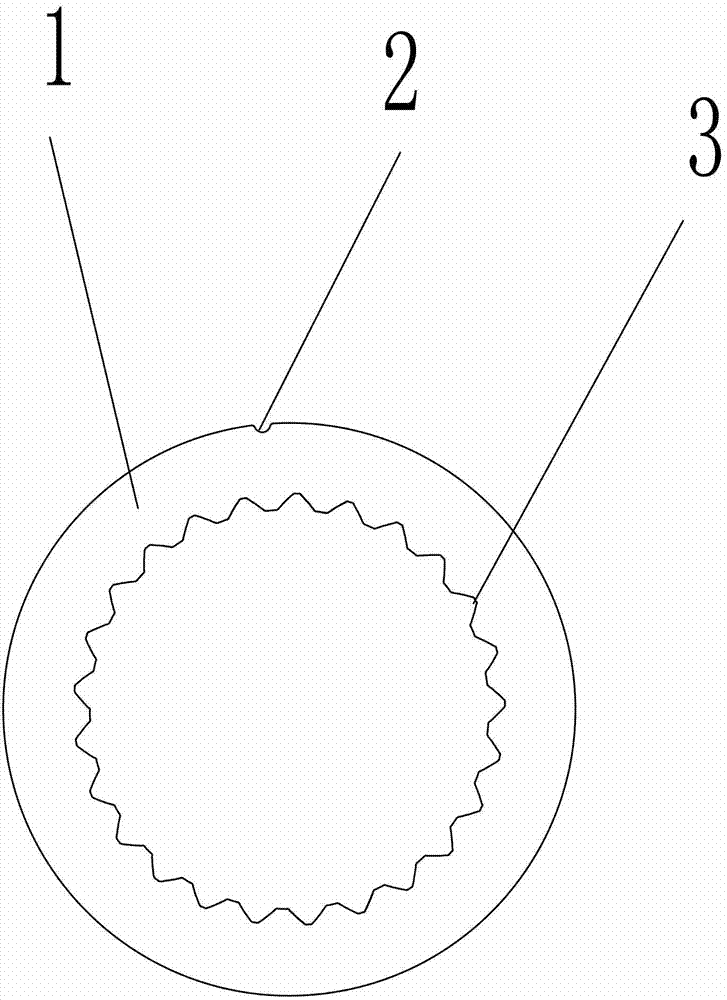

[0034] Such as figure 1 , figure 2 , Figure 11 As shown, the spline ring gauge is cylindrical, and the inner spline 3 is arranged on the inner cavity wall of the spline ring gauge, and the length of the spline ring gauge is equal to the length of the sliding sleeve spline 16 of the sliding sleeve 14, and The outer wall of the spline ring gauge is provided with a tool relief groove 2 in the axial direction, which is convenient for processing and low in cost.

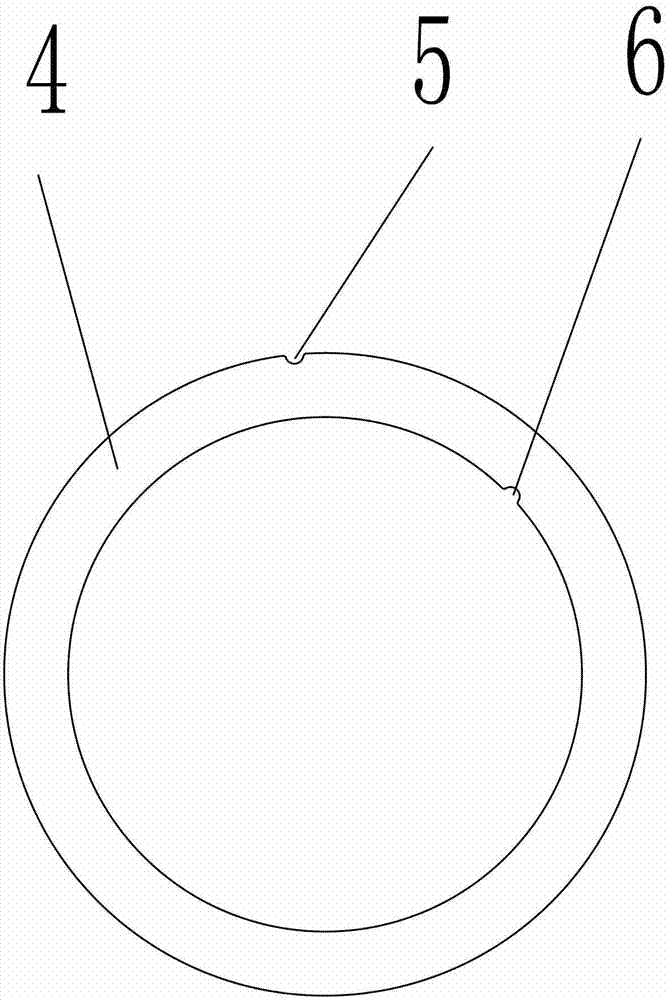

[0035] Such as image 3 , Figure 4 , Figure 11 As shown, the shaft sleeve ring gauge 4 is cylindrical, and the length of the shaft sleeve ring gauge is equal to the length of the sliding sleeve journal 15 of the sliding sleeve 14, and an outer groove 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com