Unitary plastic conductivity sensor

A conductivity sensor, plastic technology, applied in the direction of material electrochemical variables, material resistance, fluid resistance measurement, etc., can solve problems such as cost leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

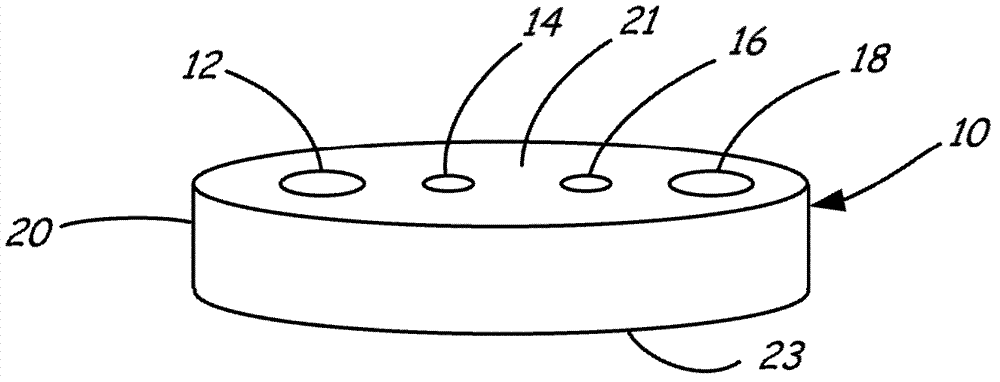

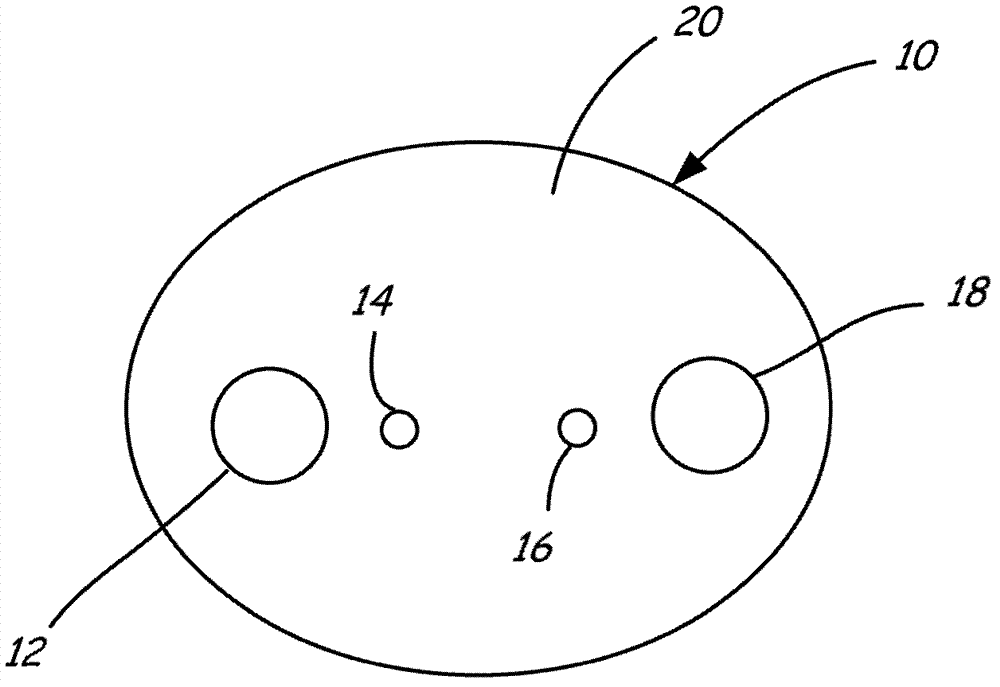

[0014] figure 2 and 3 are perspective and top views of a monolithic plastic conductivity sensor 10 according to an embodiment of the invention. As used herein, "plastic" is intended to mean a synthetic organic polymer that, while soft, can be molded into shape and then set into a rigid or slightly elastic form. Sensor 10 includes at least two and preferably four conductive electrodes 12 , 14 , 16 , 18 disposed within an insulating sensor body 20 . The illustrated sensor body has a pair of opposing faces 21, 23 and a side wall 25 extending therebetween. Each of the conductive electrodes 12 , 14 , 16 , 18 extends from the first face 21 through the sensor body 20 to the second face 23 . In use, the faces 21, 23 will be in direct contact with the sample solution to determine the conductivity of the sample solution. like image 3 As shown, when four electrodes are used, they are preferably collinear with each other.

[0015] The entire conductivity sensor 10 is considered mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com