Control method for motion mutation phenomenon in compensation of five-axis face milling cutter

A technology of tool compensation and mutation phenomenon, which is applied in the direction of program control, computer control, general control system, etc., and can solve the problems of increased change in the previous interval and decreased processing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

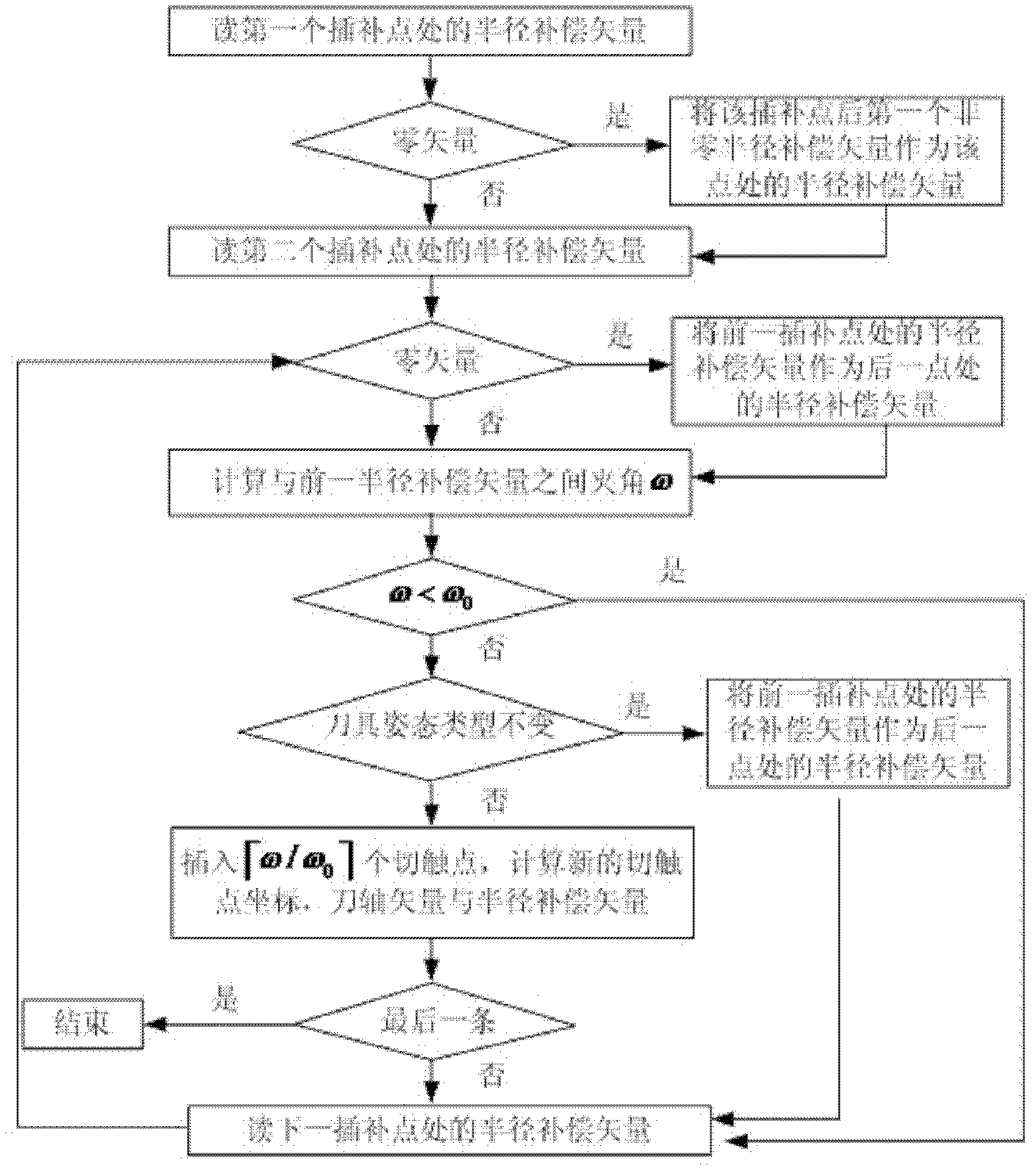

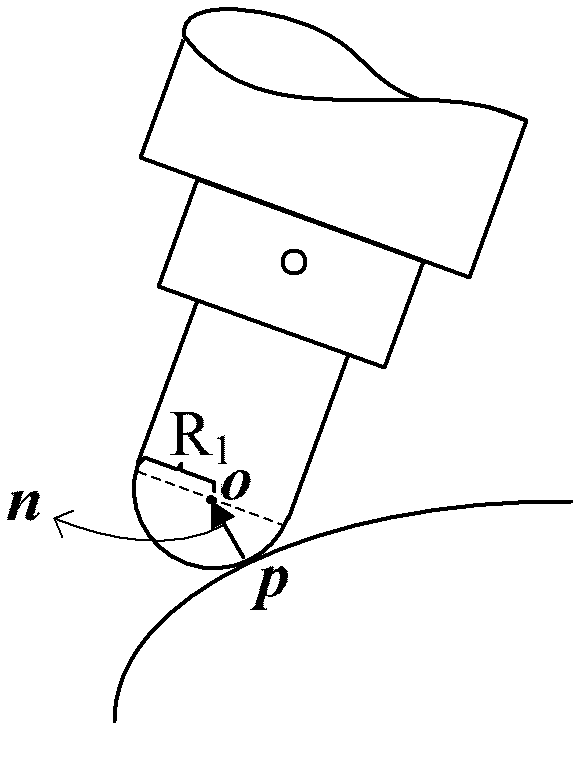

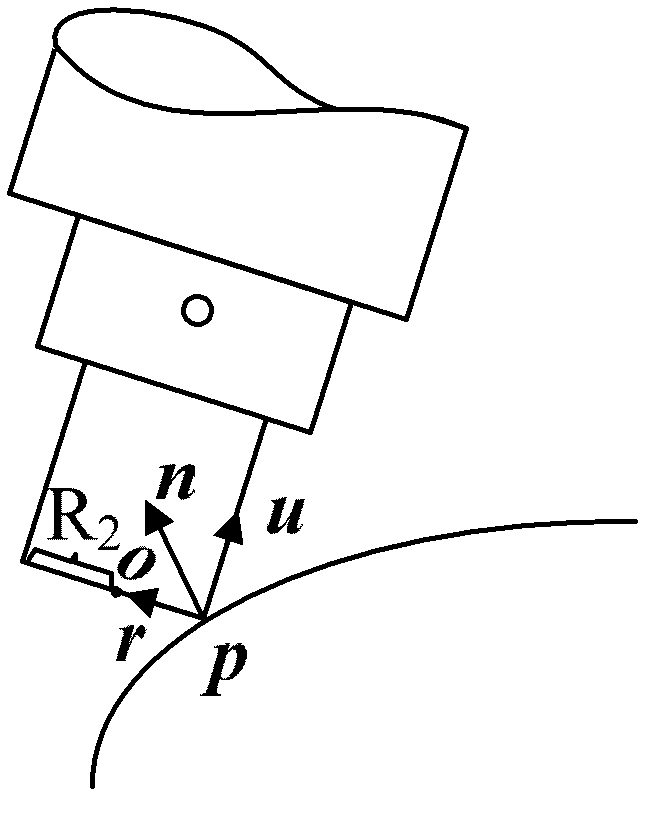

[0057] figure 1 It is a flow chart of the method of the present invention. As shown in Figure 2, there are three kinds of common knives-ball-end knives, flat-bottomed knives and ring knives. Let p be the position vector of the cutting point, o be the position vector of the tool center point, n be the normal vector of the machined surface, u be the direction vector of the tool axis, and r be the radius compensation vector. Among them, the surface normal vector, tool axis vector and compensation vector are all unit vectors. R 1 is the cutter radius of the ball-end cutter, R 2 is the tool radius of the flat bottom knife, R 3 is the tool radius of the annular knife, R 4 is the cutting edge radius of the ring knife.

[0058] The general formula of ball nose cutter radius compensation vector is:

[0059] r=n (1)

[0060] The general formula...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap