Criterion Analysis Method for Dry Tank Combustion Near Fuel Tank Under Impact of Metal Fragments

A technology for metal fragments and fuel tanks, applied in electrical digital data processing, special data processing applications, instruments, etc., to improve survivability, reduce the probability of explosions, and have a simple and intuitive expression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

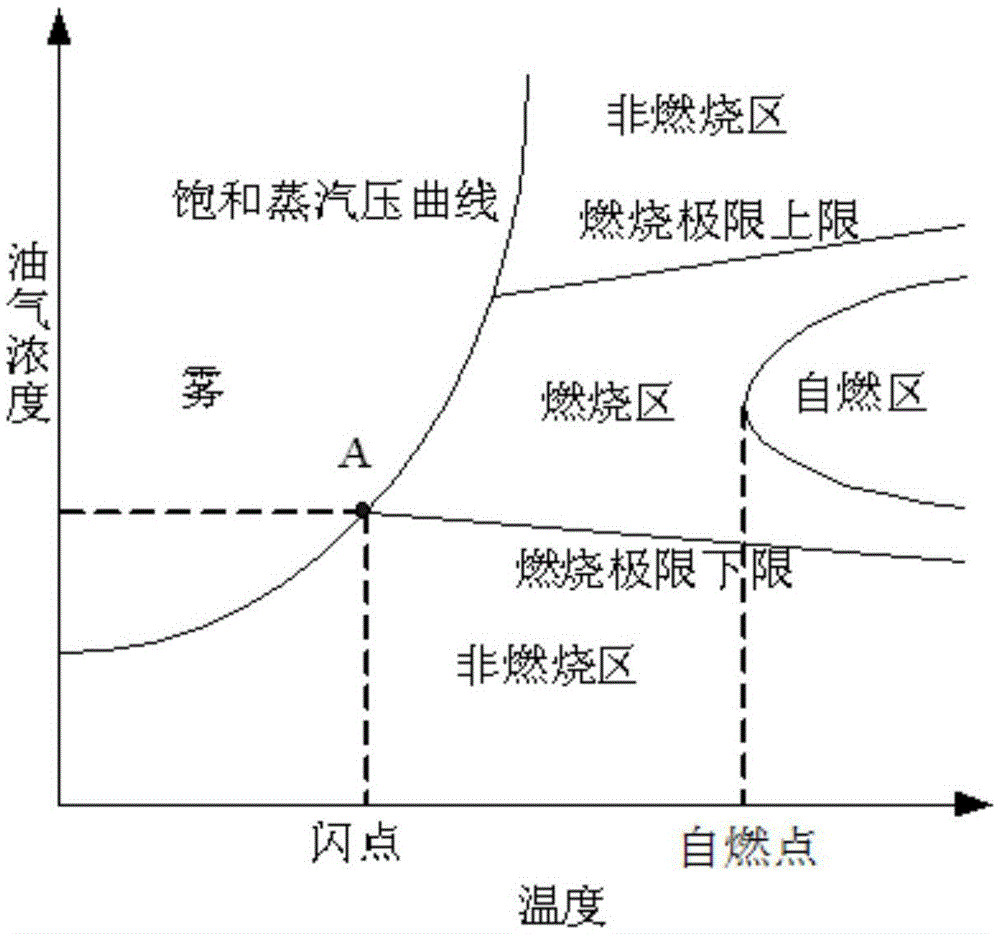

[0035] This embodiment relates to a quantitative analysis method for the continuous combustion criterion of the dry compartment near the fuel tank at different flight altitudes.

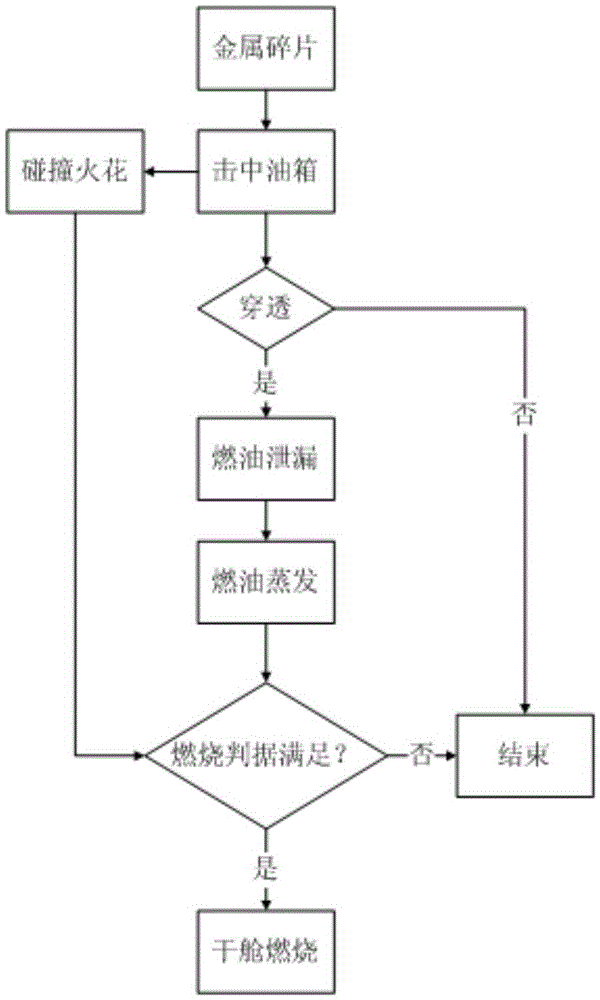

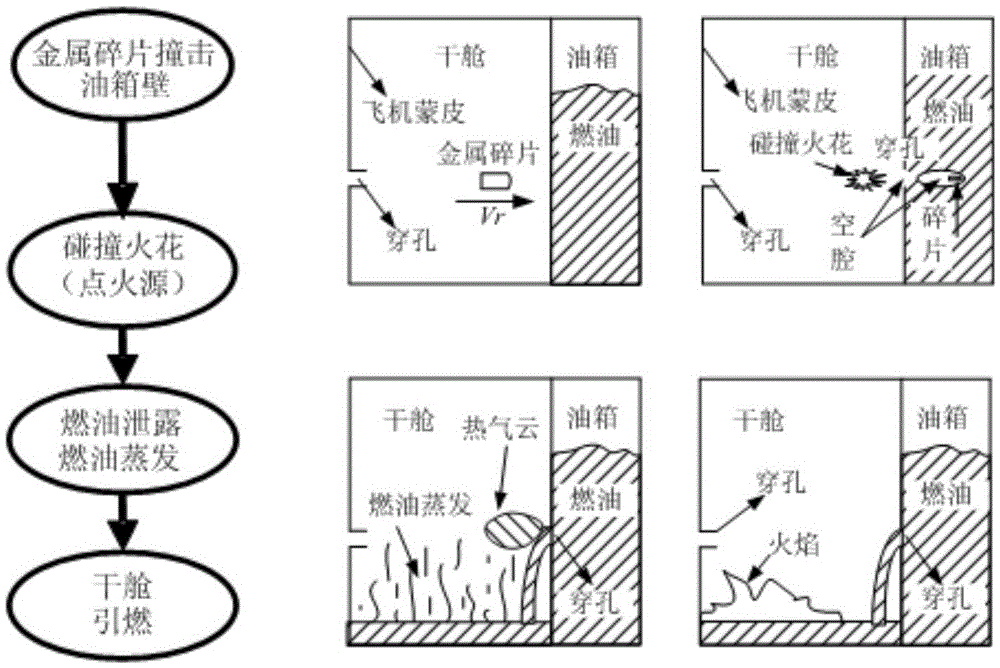

[0036] This embodiment simplifies the fire process of the dry compartment near the fuel tank under the condition of high-speed metal fragment penetration into six stages, as figure 1 and figure 2 shown, where:

[0037] Stage 1, high-speed metal fragments hit the fuel tank, forming collision sparks, that is, the ignition source of the dry cabin; the formation of the ignition source is mainly due to the high-speed metal fragments generated when the engine blade structure fails, and the fragments are in the process of breaking through the aircraft fuel tank wall. The friction of the fuel tank wall, the metal particles splashed from the metal surface of the fragments have a ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com