A kind of high safety lithium ion battery and preparation method thereof

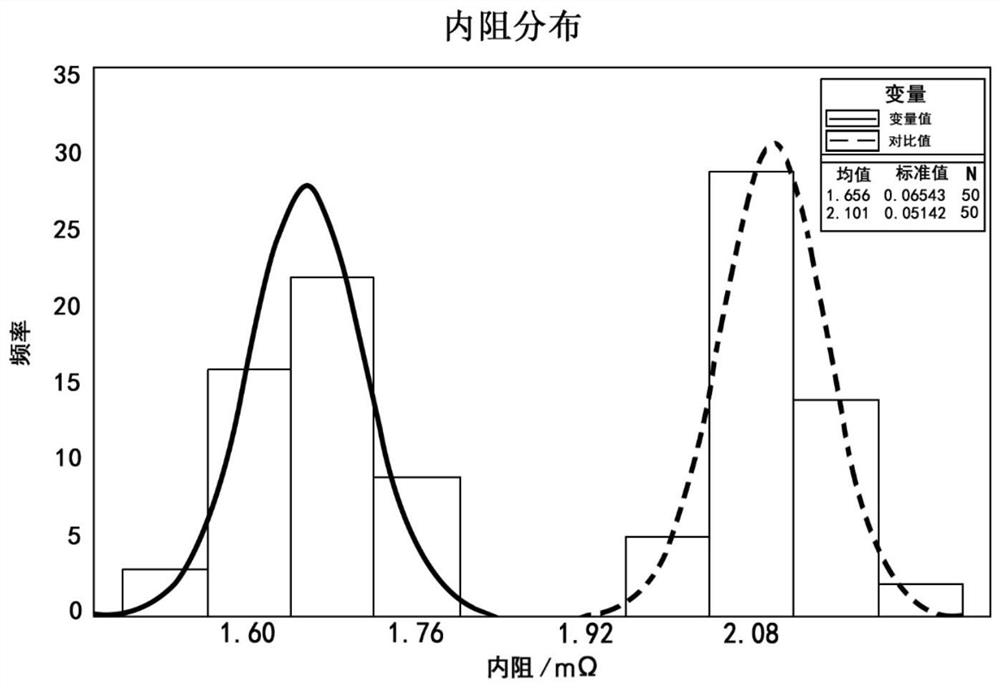

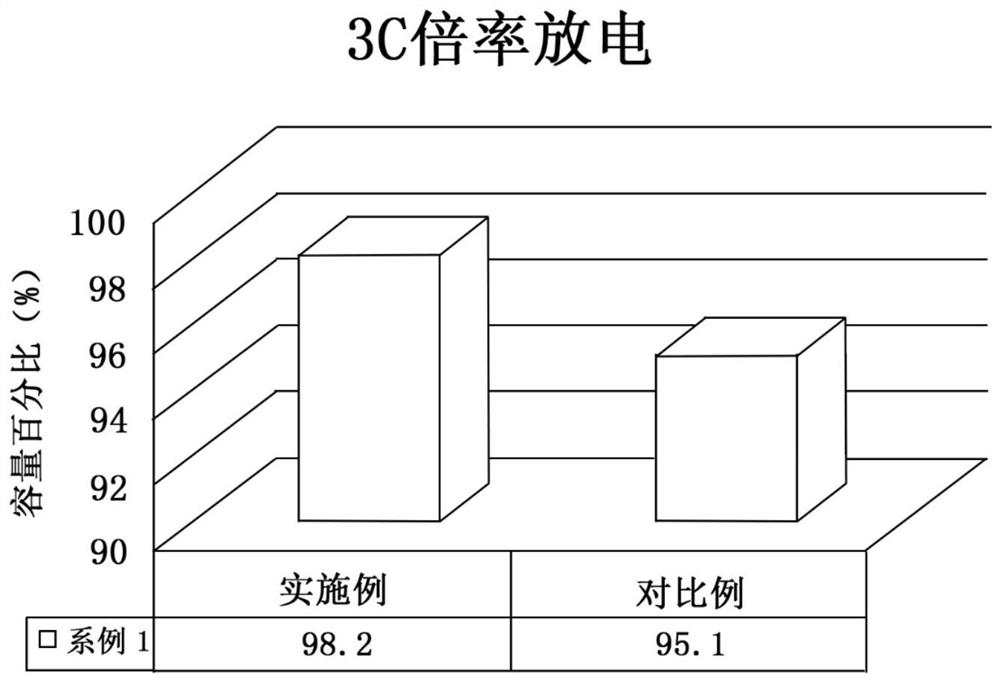

A lithium-ion battery, high-safety technology, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve problems affecting battery cycle performance, increasing battery internal resistance, failure of negative electrode graphite, etc., to achieve excellent Electronic conductivity, increase battery rate, and reduce the effect of contact internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

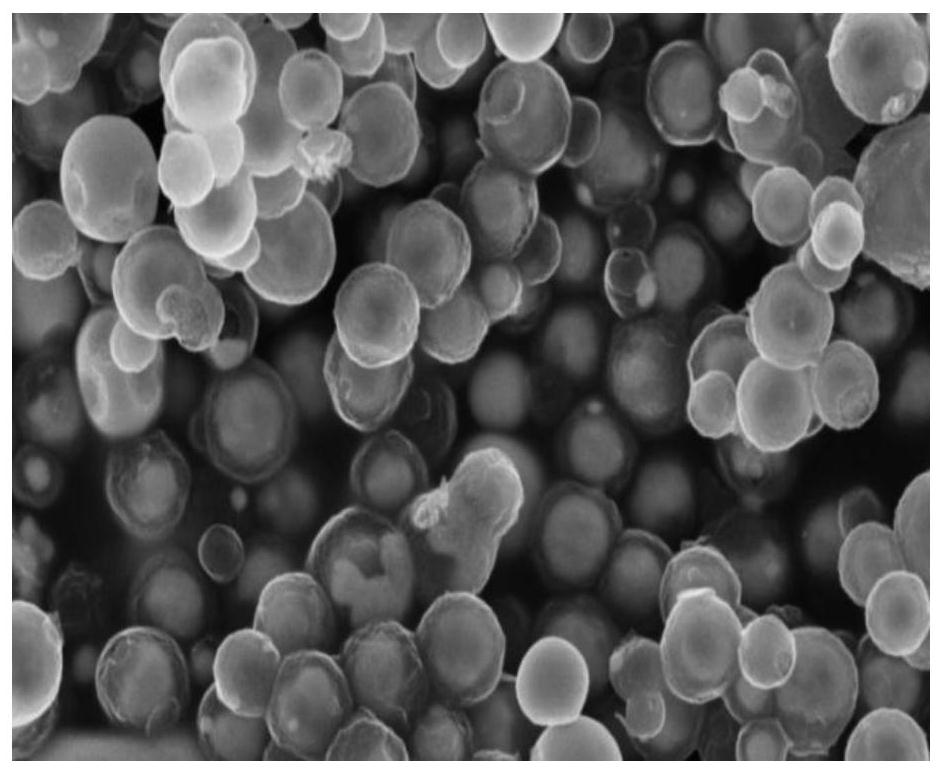

[0024] Preparation of carbon-coated triphenyl phosphate flame retardant (TPP): first, mix triphenyl phosphate particles and catalyst at a molar ratio of 20-30:1, mix organic gas acetylene with nitrogen as compressed gas, and pass it into In the quartz tube that removes oxygen in advance, the metal oxide of nickel is used as the catalyst, and the acetylene gas is cracked by catalytic action at a certain temperature to form a carbon source. The carbon source diffuses through the catalyst, and carbon nanotubes grow on the surface of the catalyst until the catalyst particles are completely Wrapped by a carbon layer, the growth of carbon nanotubes ends, and a carbon-coated triphenyl phosphate flame retardant (TPP) is prepared. The thickness of the carbon coating layer in the obtained carbon-coated triphenyl phosphate flame retardant is 2- 3 μm.

[0025] In advance, the polyvinylidene fluoride binder is dissolved in a certain amount of solvent N-methylpyrrolidone, and stirred at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com