Crankshaft mirror

A crankshaft milling machine, X-axis technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve the problem of hindering the swinging movement of the swinging head 105, and achieve the effect of smooth and stable swinging movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

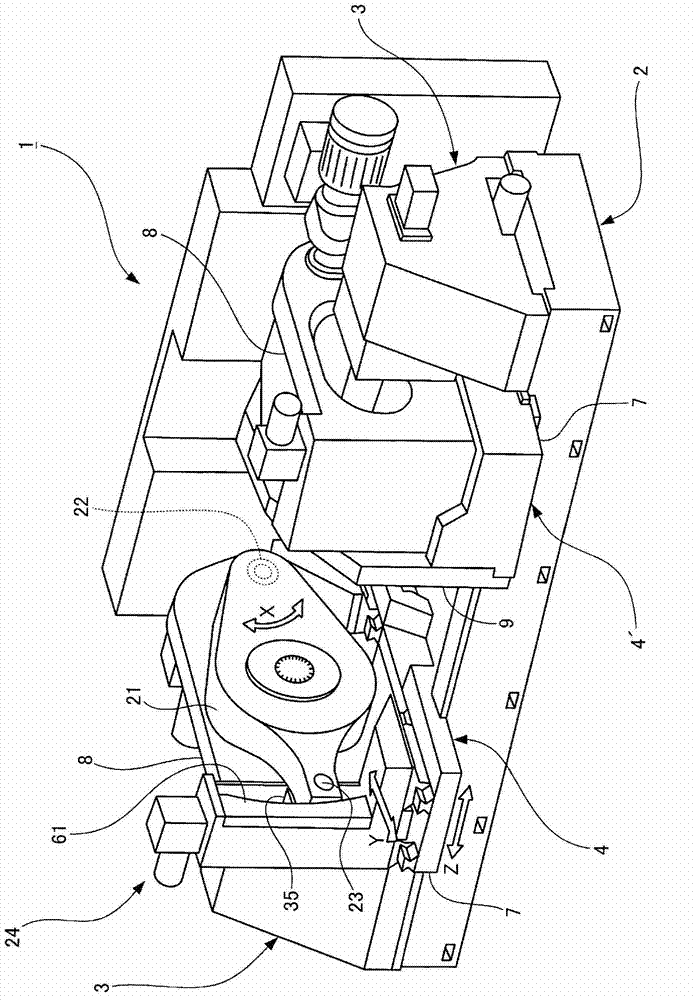

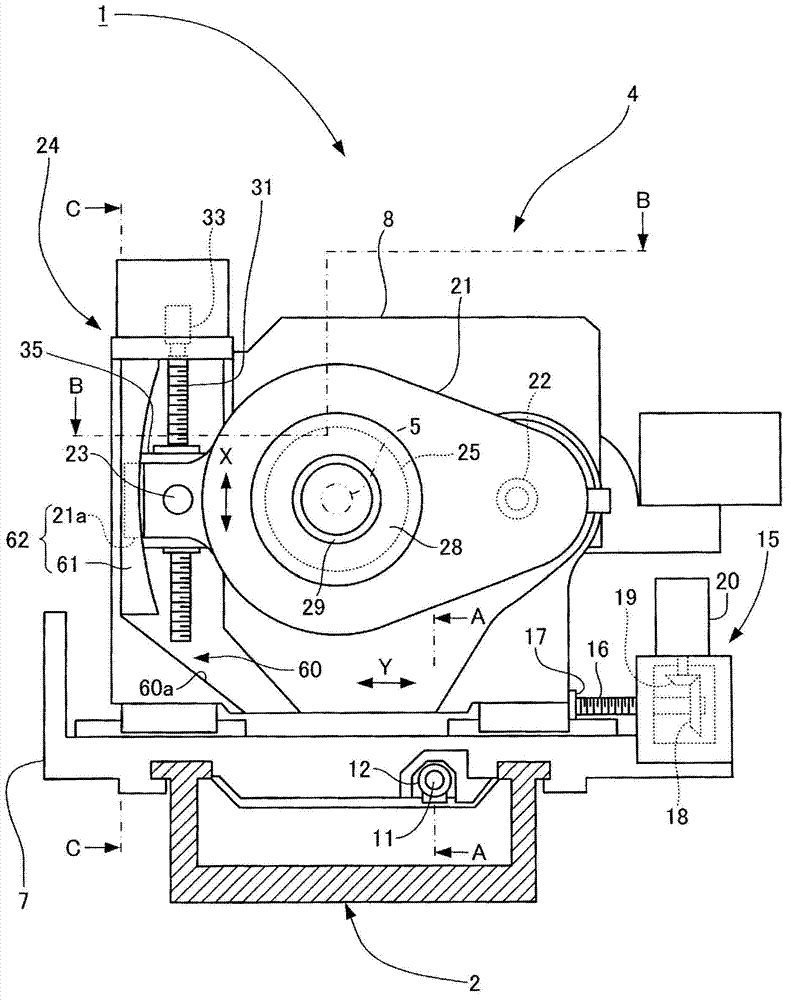

[0051] figure 1 >

[0052] figure 1The shown crankshaft milling machine 1 is provided with: a bed 2 constituting a base as the base of the main body; 3 between two tool units 4, 4'.

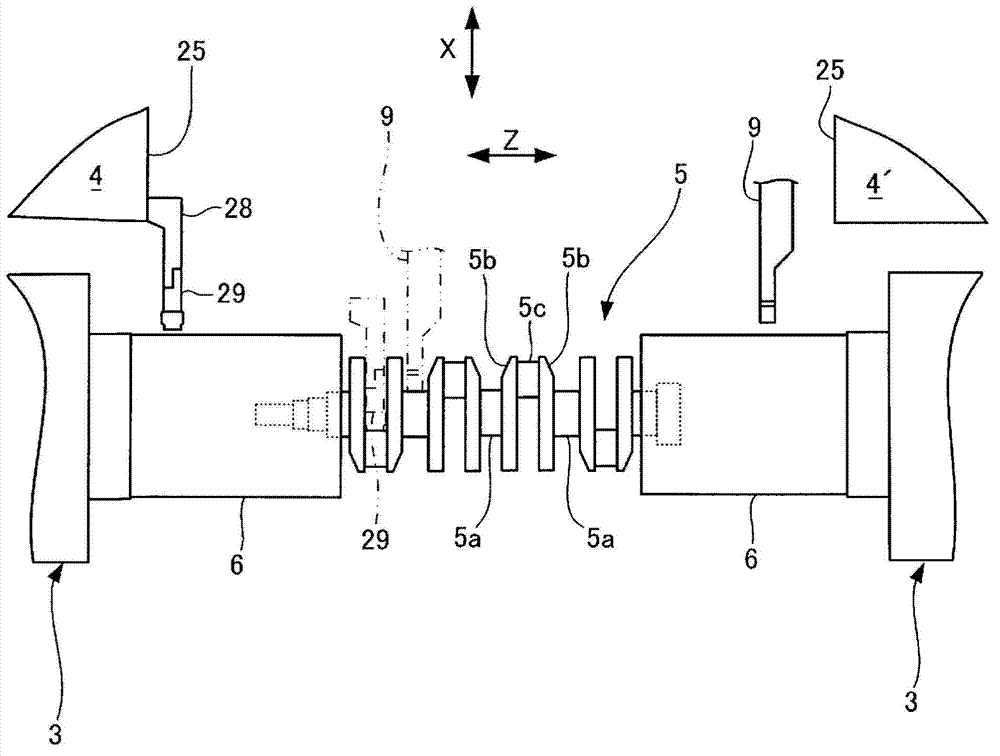

[0053] figure 2 >

[0054] Such as figure 2 As shown, chucks 6 for clamping a workpiece (crankshaft) 5 are disposed on opposing surfaces of the workpiece seats 3, 3, respectively.

[0055] figure 2 >

[0056] The workpiece 5 is, for example, a crankshaft used in a 4-cylinder engine. The workpiece 5 has desired spindle necks 5 a arranged at predetermined intervals in the direction along the horizontal axis. A pin journal portion 5c is formed between the adjacent main journal sections 5a via a weight portion 5b.

[0057] Figure 1~3 >

[0058] Such as figure 1 As shown, each tool unit 4, 4' is equipped with a workpiece 5 to be processed (refer to figure 2 ) is movably arranged on the saddle 7 on the bed 2 in the Z-axis direction parallel to the horizontal axis.

[0059] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com