Multi-layer steamed bread automatic baking oven

A technology for baking ovens and puff pastry, which is applied in the field of automatic baking ovens for baking traditional famous puff pastry, can solve problems such as low production efficiency, and achieves the advantages of small footprint, compact machine, and reduction of oxidative substances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

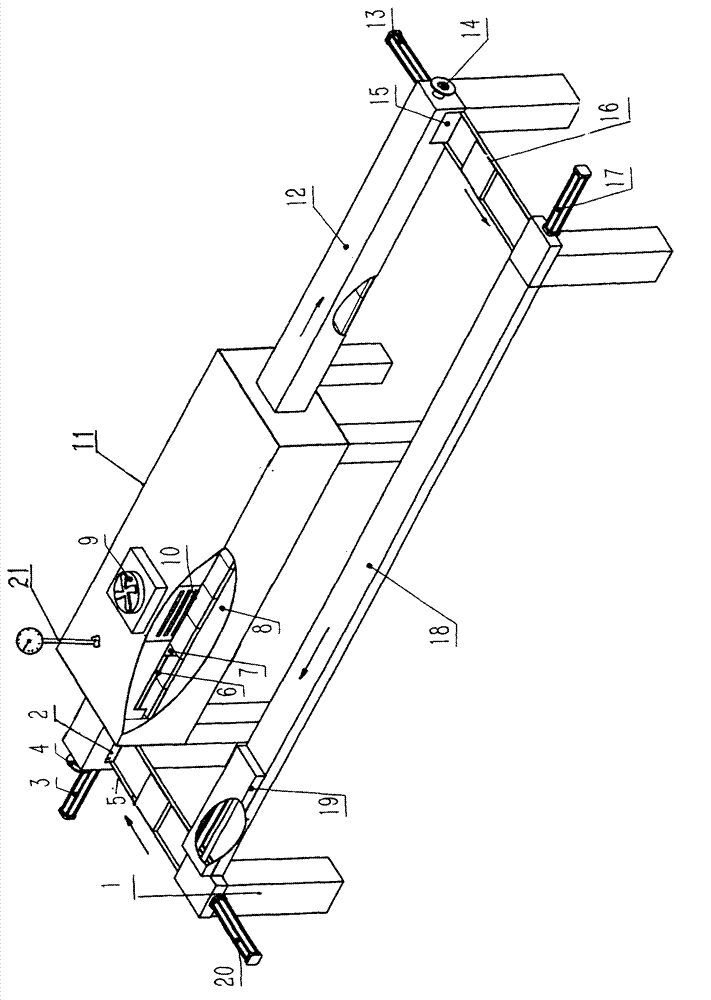

[0012] Embodiment: The automatic baking oven for puff pastry of the present invention is composed of a rectangular revolving track set on the frame foot 1, a tunnel-type electric furnace set in partitions, and a pneumatic or hydraulic push rod. The rectangular revolving track is respectively the longitudinal front track 18, the longitudinal rear track 12, the transverse left track 5 and the transverse right track 16. The longitudinal front track 18 is a closed tunnel-type track, and a preheating furnace 19 is provided in its second half. The longitudinal rear track 12 is also a closed tunnel track, and a baking oven 11 is provided in its first half, and the second half is a furnace temperature decreasing zone. The transverse track is an open trough track to facilitate loading and unloading, wherein the transverse left track 5 is the loading area, and the transverse right track 16 is the unloading area. The porcelain material plate for baking the layer cake is pushed forward b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap