Composite imitation metal sheet (coiled) material and production process thereof

A production process and metal sheet technology, applied in the field of composite imitation metal sheet and its production process, to achieve outstanding decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

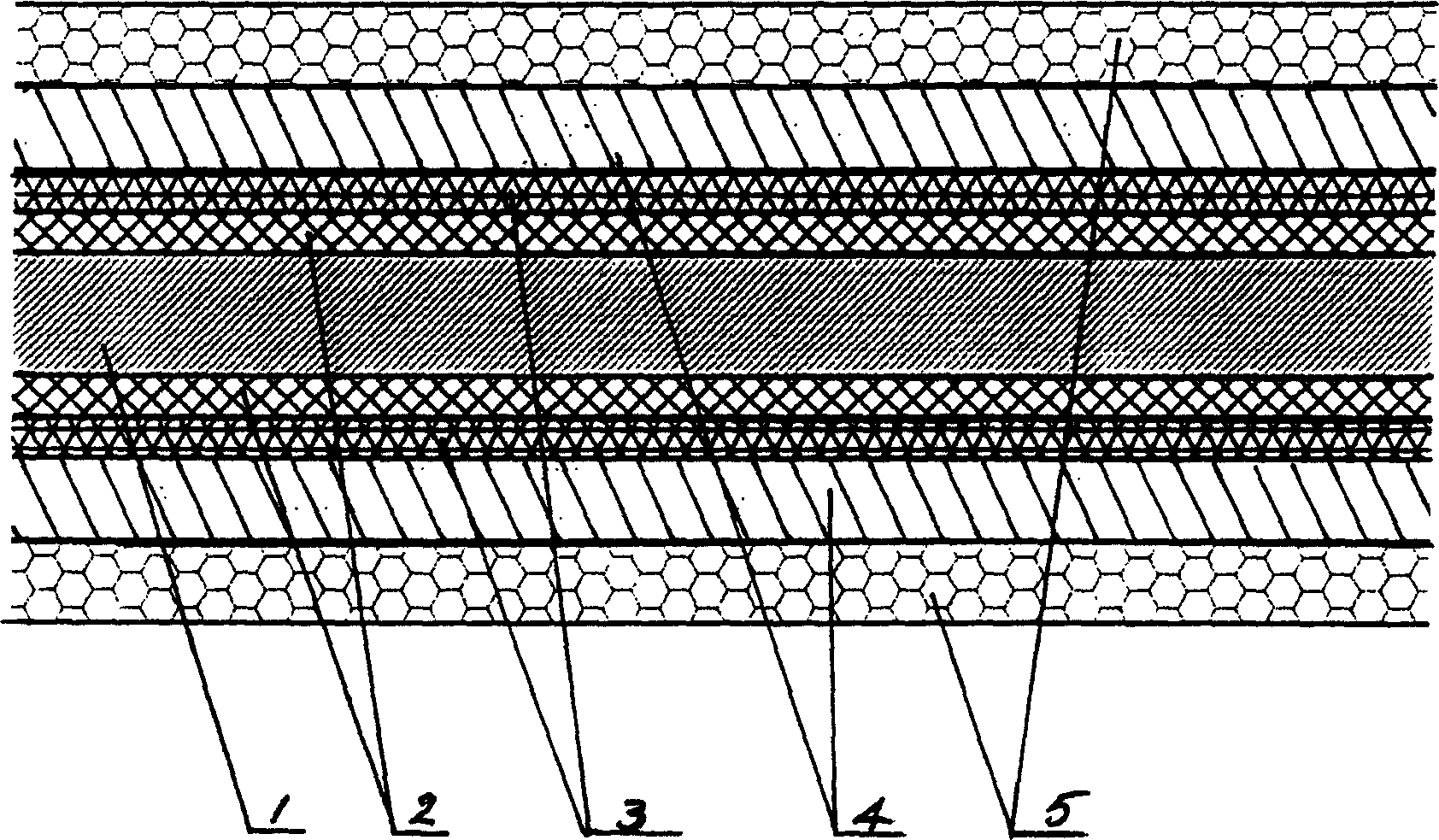

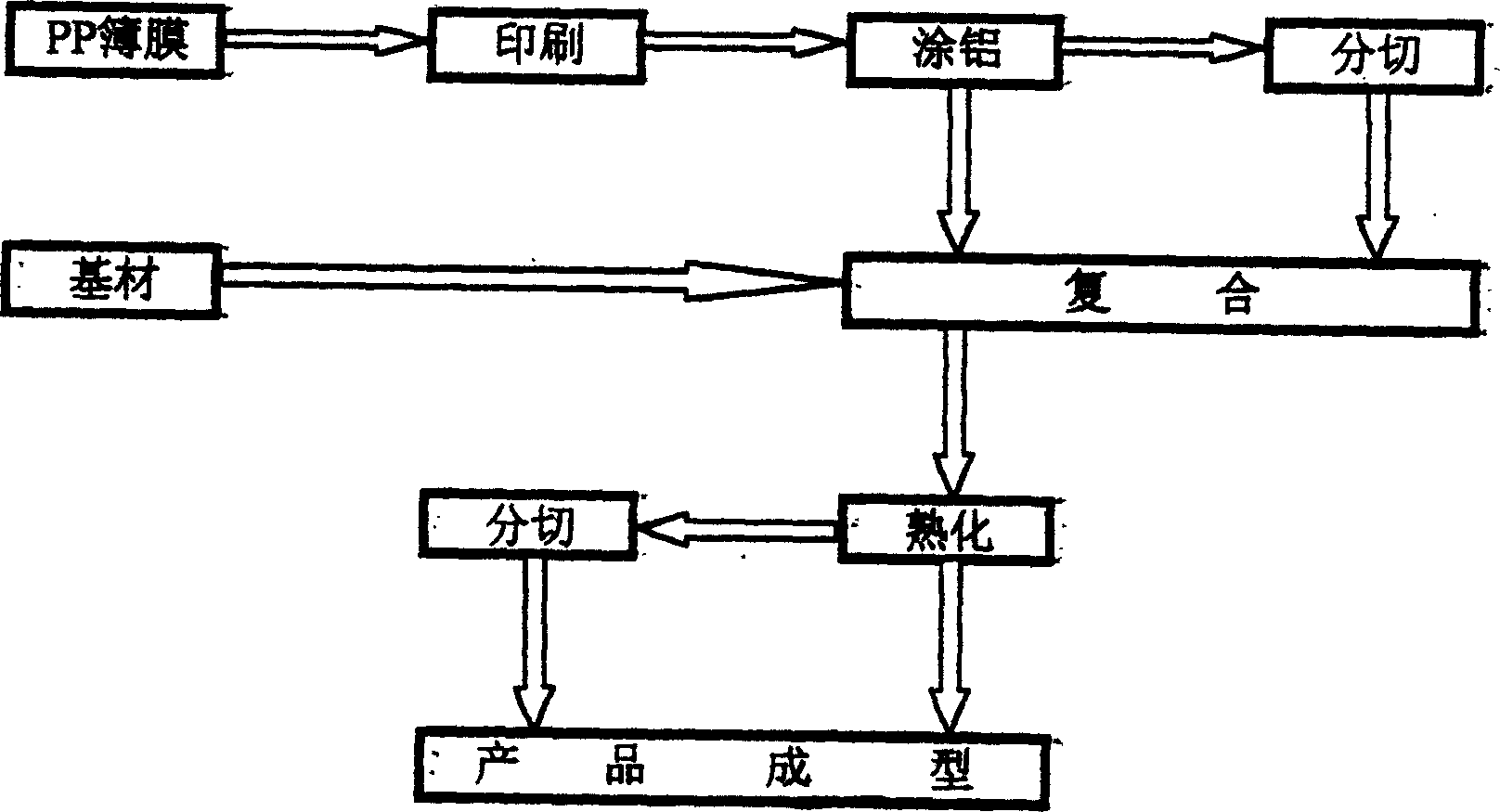

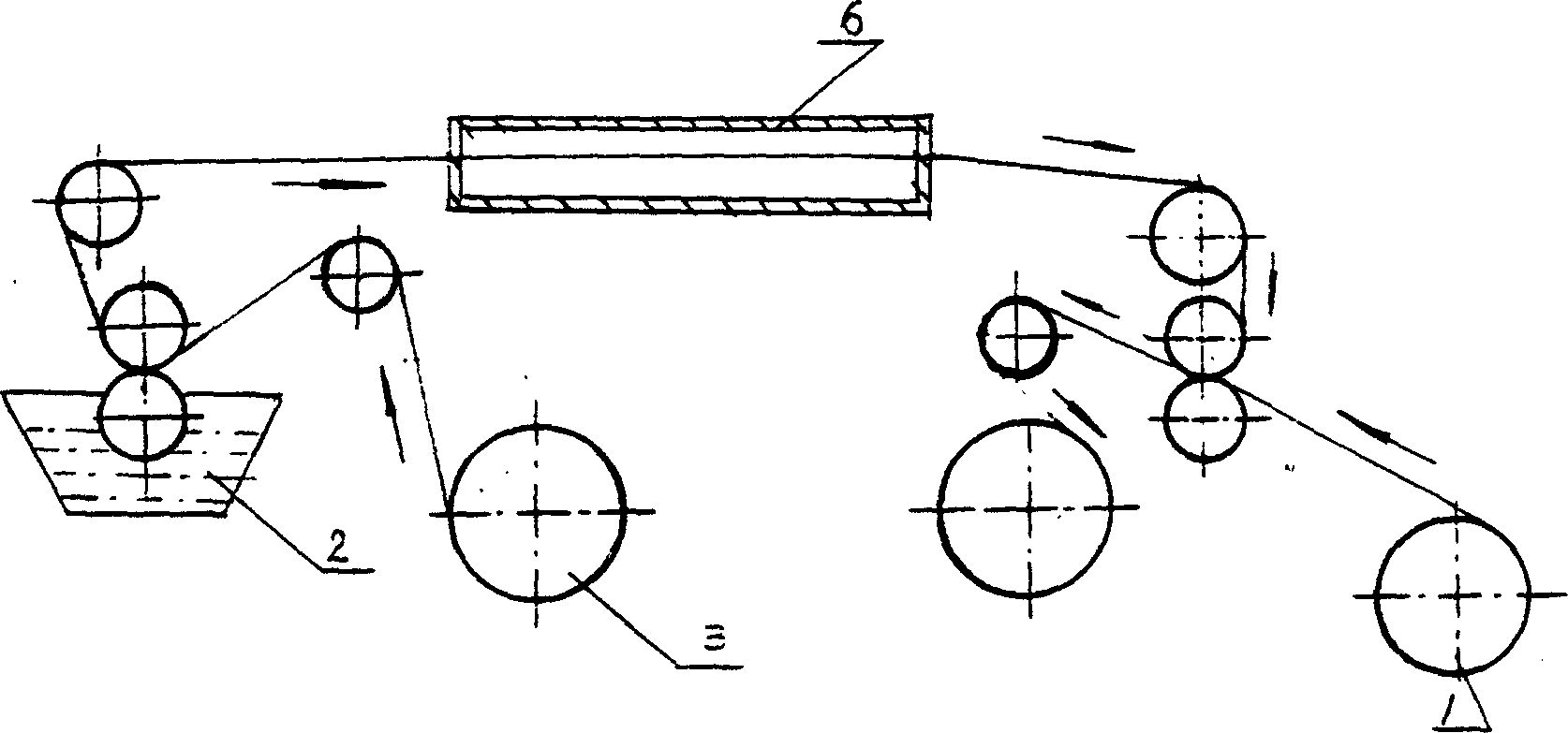

[0016] See attached figure 1 , 2 , 3, at first imitation metal film is processed, add 1.5Kg1702B sizing material by 0.035Kg yellow pigment and add 1Kg ethyl acetate solvent dilution and mix as printing pigment, carry out screen printing on the single side of film 5, form printing layer 4 , as a colored substrate, the printed layer 4 of the colored substrate is vacuum-plated at 1400°C to form a metal-like film, and then coated with butanone solvent on the surface of the vacuum-coated aluminum layer 3 of the metal-like film. A-969V is compounded with A-5 adhesive 2 and substrate 1, dried in a drying room 6 at a temperature of 80°C, and compounded into a composite imitation metal sheet, which is cured at a temperature of 60°C and cut into coils , inspection, storage.

Embodiment 2

[0018] Firstly, process the imitation metal film, dilute and mix 0.035Kg yellow pigment plus 1.5Kg LY-7328 and LY-7328H glue plus 1Kg butyl acetate solvent as printing pigment, and screen print on one side of the plastic film. Form the printing layer 4, as a colored substrate, on the printing layer 4 surface of the colored substrate, carry out vacuum aluminum plating at 1400 ° C to form a metal imitation film, and then on the surface of the vacuum aluminum plating layer 3 of the imitation metal film and Squeeze the adhesive 2 between the substrates 1 for compounding. The adhesives are A3230 and I3000, which are dried in a drying room 6 at a temperature of 80°C, and compounded into a composite imitation metal sheet, and then cured at a temperature of 60°C. , cut into rolls, and then cold processed, using the method of stamping, made into folding boxes, inspected, and put into storage.

Embodiment 3

[0020] Firstly, the imitation metal film is processed, and after 0.035Kg yellow pigment plus 1.5Kg acrylic varnish sizing material is diluted and mixed with 1Kg ethanol solvent, it is used as a printing pigment, and screen printing is carried out on one side of the plastic film to form a printing layer 4. Substrate, on the printed layer 4 of the colored substrate, carry out vacuum aluminum plating at 1400 ° C to form a metal imitation film, and then coat the surface of the vacuum aluminum plating layer 3 of the imitation metal film with cyclohexanone solvent to dilute and bond Agent 2 is used to bond the substrate 1 for compounding. The adhesive is cured at 60°C with A-626 and A11, and compounded into a composite imitation metal sheet, which is cut into coils and then thermally processed. Under hot pressing, it is made into a food tray, inspected, and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com