Anti-popping zipper with guide piece

A guide sheet and zipper technology, applied in the field of zippers, can solve the problems of enlarged gap between the bottom plate and the cover plate, easy damage and tearing of zippers, and falling of double-tooth zipper heads, so as to achieve not easy to tear, reduce tension, and reduce fatigue degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

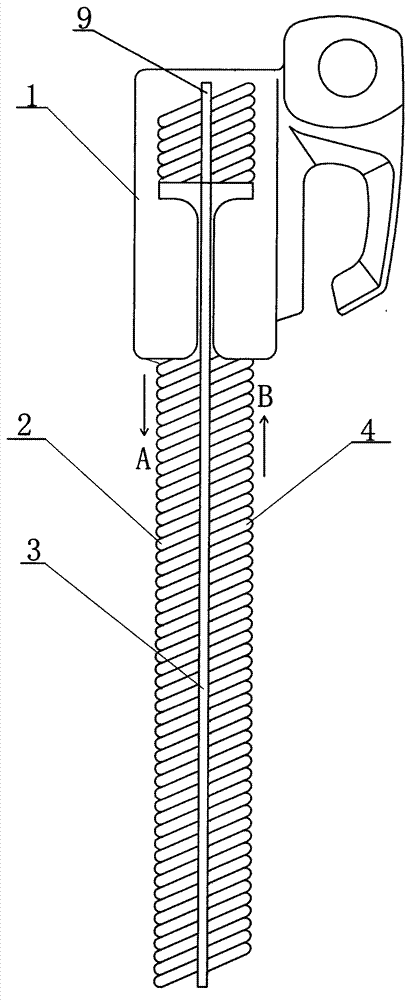

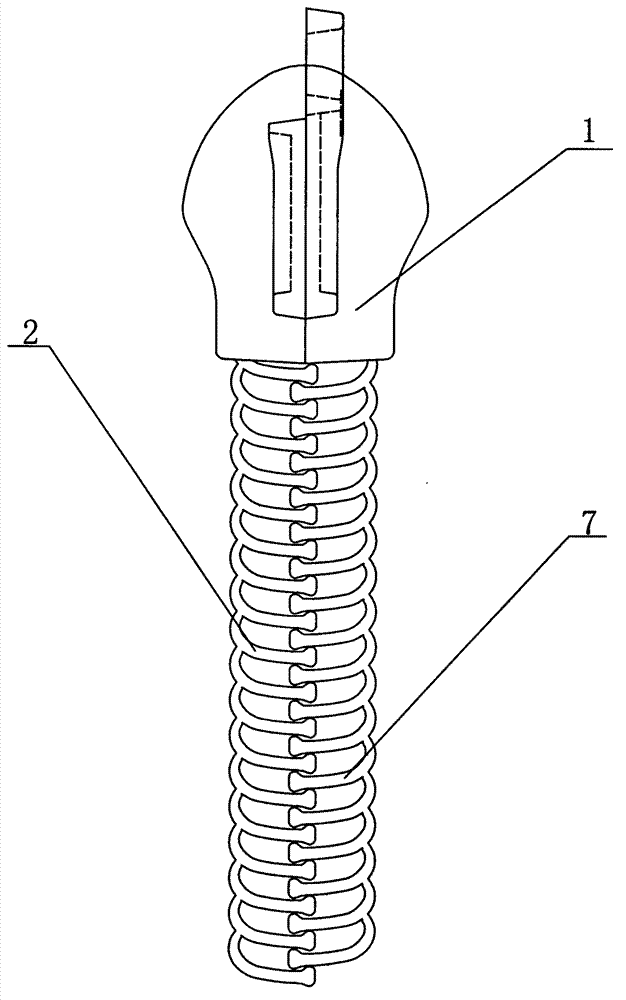

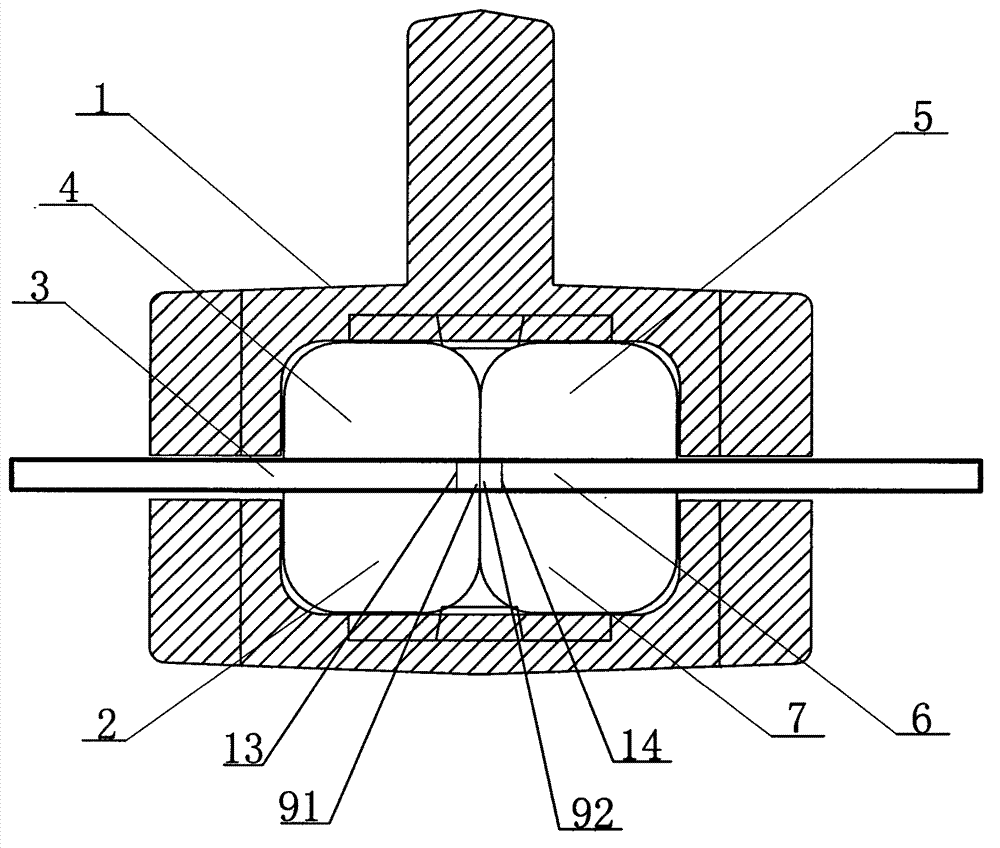

[0029] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0030] see Figure 1-5 , the explosion-proof zipper with the guide piece provided by the present invention comprises the left loop of the zipper, the right loop of the zipper and a double-tooth zipper puller 1; the left loop of the zipper is composed of the lower left teeth 2, the left cloth belt 3 and the upper left teeth 4, The right loop of the zipper is composed of the upper right teeth 5, the right cloth belt 6 and the lower right teeth 7, the lower left teeth 2 are engaged with the lower right teeth 7, the upper left teeth 4 are engaged with the upper right teeth 5, and the double-tooth zipper puller 1 Bite with the combination of lower left teeth 2, lower right teeth 7, upper left teeth 4, and upper right teeth 5;

[0031] The double-tooth zipper puller 1 is provided with a pull column 8, and a guide piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com