Dust collecting device of dust collector producing no raise dust and being easy to clean

A technology for dust collectors and vacuum cleaners, applied in suction filters, spray devices, liquid spray devices, etc., can solve problems such as difficulty in cleaning, flying dust, polluting the environment, etc., to increase quality, prevent dust flying, and reduce the generation of static electricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is a detailed description of the dust-free and easy-to-clean vacuum cleaner dust collection device of the present invention with reference to the accompanying drawings and embodiments. In the drawings of the present invention, the same symbols are used for the same parts as those of the prior art.

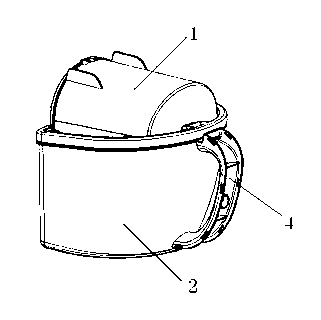

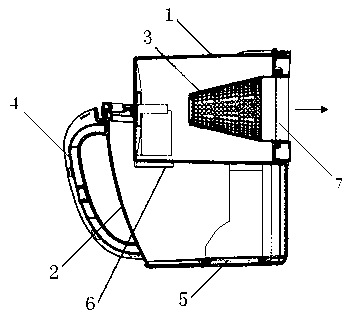

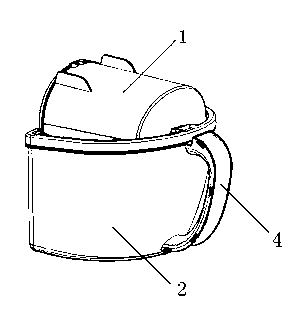

[0037] image 3 It is an appearance view of the dust collecting device of the dust-free and easy-to-clean vacuum cleaner of the present invention. like image 3 As shown, the dust-free and easy-to-clean vacuum cleaner dust collection device of the present invention includes a dust collection bucket 2 and a cyclone separator 1 installed above the dust collection bucket. A filter is installed horizontally inside the barrel of the cyclone separator, and the front end of the filter forms an air outlet. One side of the dust collecting barrel 2 is provided with a handle 4, the bottom of the dust collecting barrel is provided with an air inlet connected to the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com