Water dispenser photocatalytic gas phase sterilizer

A technology of photocatalytic gas and sterilizer, which is applied in disinfection, chemical instruments and methods, and dispersed particle filtration, etc. It can solve the problems of excessive microbial content in water, polluted water sources, unsuitable for drinking, etc., and achieves easy recycling and energy-saving service life. , easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

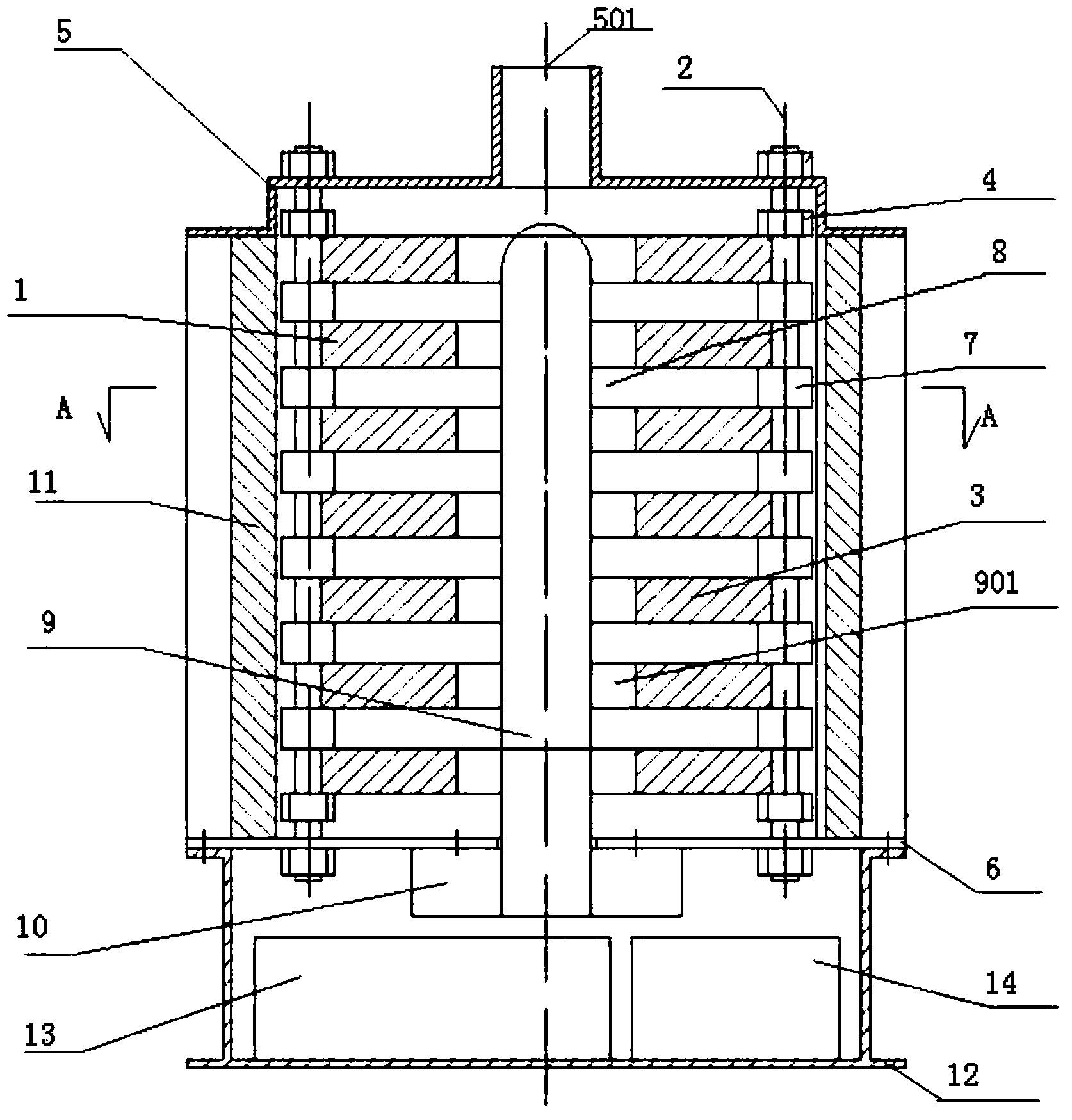

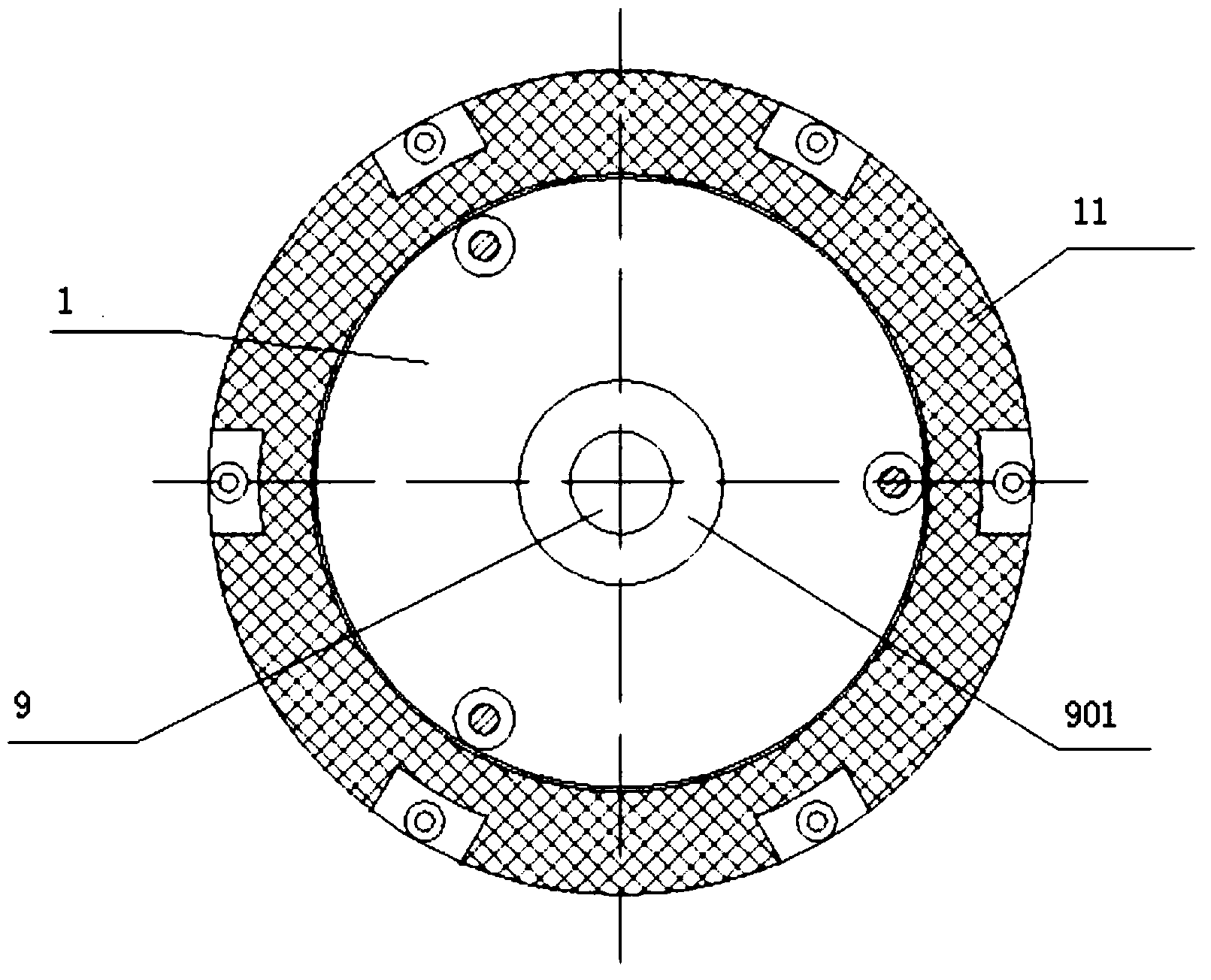

[0016] as attached figure 1 and 2 As shown, a water dispenser photocatalytic gas phase sterilizer, it includes not less than one piece of photocatalytic pottery 1 with a central opening, the photocatalytic pottery 1 is stacked into a cylinder 3 through a screw 2, and the screw 2 is located in the photocatalytic The outer end surface of the pottery piece 1 is locked with a nut 4, and the two ends of the screw rod 2 are respectively fixed on the upper cover plate 5 and the lower cover plate 6, and the photocatalytic pottery piece 1 is separated by a gasket 7 to form a gas phase photocatalytic reaction tank 8, The central hollow of the cylinder 3 is provided with an ultraviolet lamp 9, and the lower end of the ultraviolet lamp 9 passes through the lower cover plate 6 and is fixed on the lamp holder 10. The outer periphery of the cylinder 3 is covered with a filter sponge 11, which is in a compressed state, and the upper cover The center of the plate 5 is provided with an air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com