Electrode coping and replacing all-in-one machine

An all-in-one machine and electrode technology, applied in the direction of electrode characteristics, etc., can solve the problems of automobile production capacity impact, long time required for electrode cap replacement, and inability to completely avoid line stop phenomenon, so as to achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

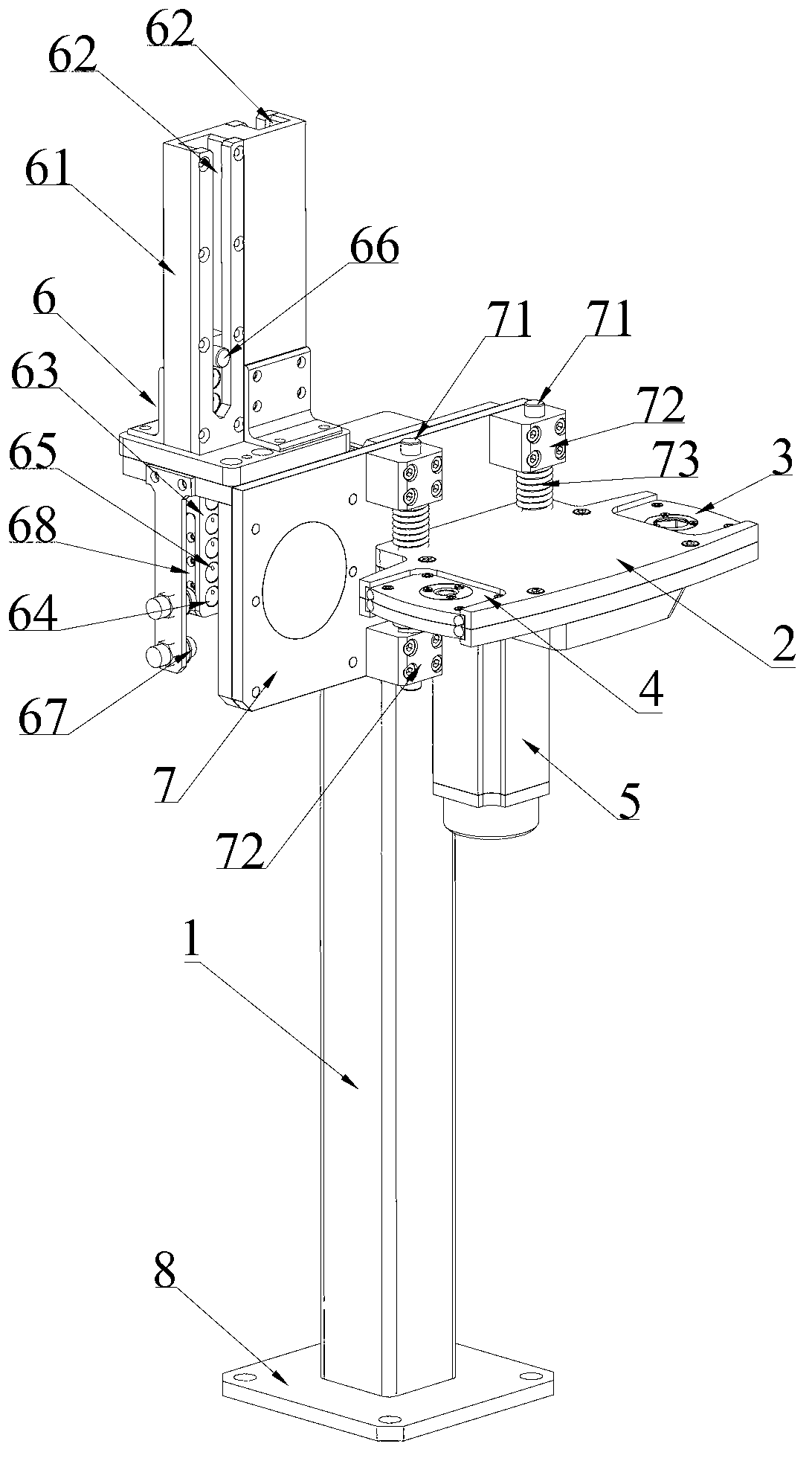

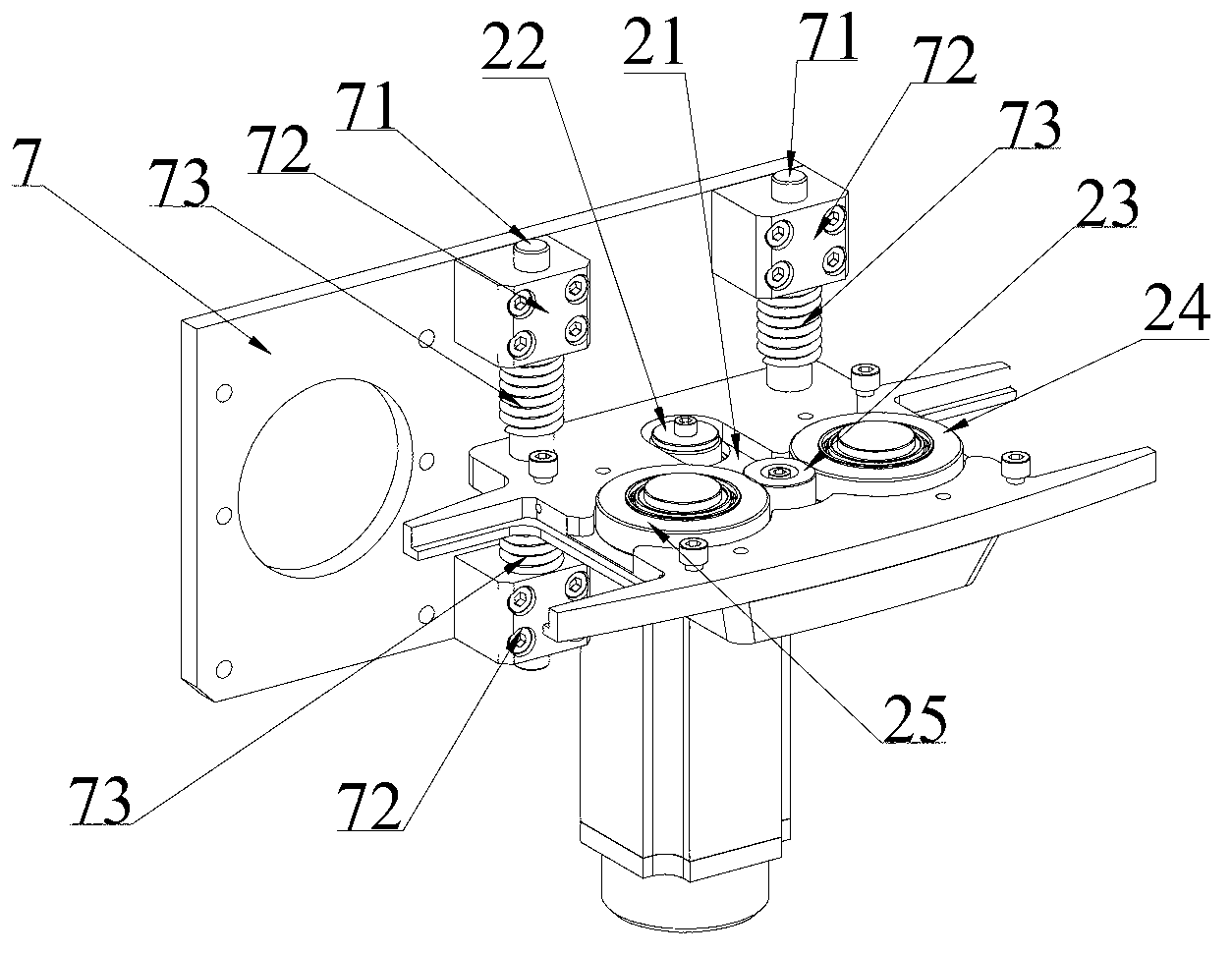

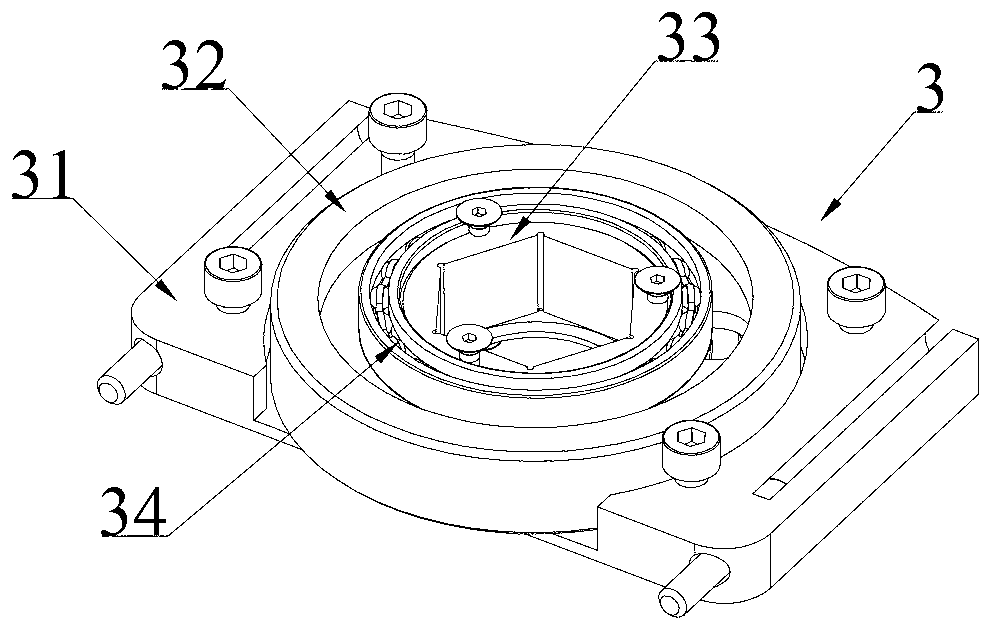

[0023] refer to Figure 1 to Figure 6 , the present invention provides an electrode grinding and replacing machine, including a frame 1, a driving head 2 arranged on the frame 1, an electrode grinding unit 3 and an electrode cap replacement unit 4 arranged on the driving head 2 , the drive head 2 is provided with a servo motor 5 for driving the electrode grinding unit 3 and the electrode cap replacement unit 4 .

[0024] In this all-in-one machine for electrode grinding and replacement, the driving machine head 2 is used as the carrier of the electrode grinding unit 3 and the electrode cap replacement unit 4, and the electrode grinding unit 3 and the electrode grinding unit 3 are driven by the servo motor 5 through the gear transmission inside the driving machine head 2. The electrode cap replacement unit 4 rotates to complete the grinding of the electrode and the replacement of the electrode cap, so that the grinding and replacement of the electrode cap can be automated and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com