Material feeding machine for edible fungi industrial culture

An edible fungus and feeder technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem that the output and quality of edible fungi cannot be improved in a large area, the feeding time and quality of mushroom beds cannot be guaranteed, and the work efficiency and feeding quality are poor. and other problems to achieve the effect of ensuring the feeding time and quality, reducing the labor intensity and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

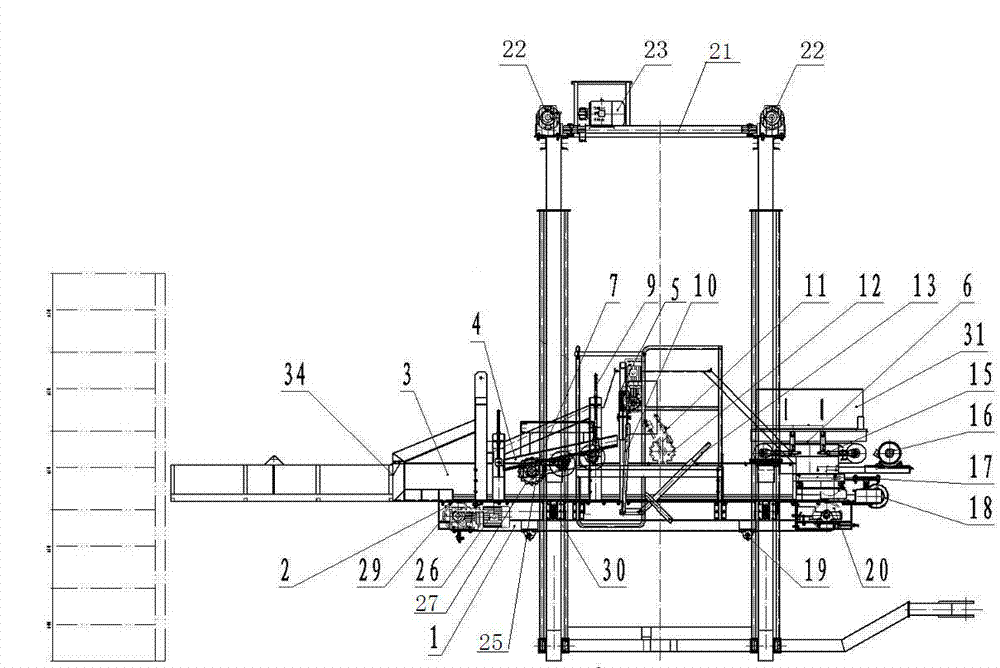

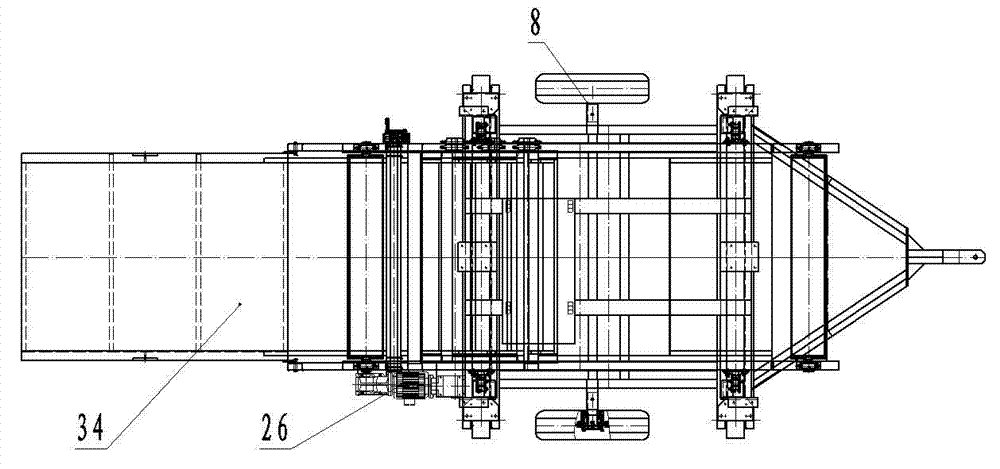

[0032] Example 1, see figure 1 , 2 . The conveying device 2 is composed of a conveyor motor reducer 26, a conveyor driving wheel 29, a conveyor driven wheel 20, and a conveyor belt. Lifting sheaves 30 are installed on both sides of the conveyor belt, and conveyor belt rollers 19 and tensioners are installed below the conveyor belt. Nylon cloth traction area 34 is installed at the front of the conveyor belt, and the conveyor motor reducer 26 drives the conveyor belt to rotate through the conveyor main wheel 29 and the conveyor driven wheel 20; Feeding device 4, thickness setting device 5, and throwing device 6 are three functional unit devices, which form the combined working body of the feeding machine;

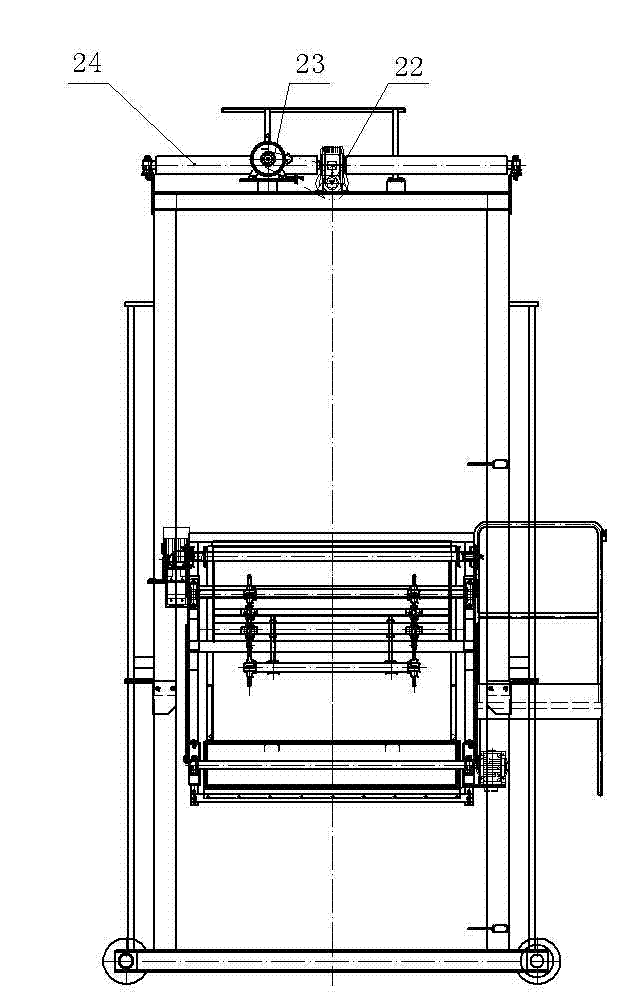

[0033] The above-mentioned pressing device 4 is composed of front, middle and rear three pressing wheels 7, a pressing adjusting lever 9, and a pressing motor 25. The three pressing wheels 7 are arranged at a certain angle, and the pressing motor 25 drives the driving wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com